Ecowool is a very convenient and profitable insulation material. However, it is still used quite rarely, giving preference to polystyrene and mineral wool. This is not surprising, since ten years ago nobody heard about ecowool in our country, and equipment for the industrial production of this heat insulator appeared only in the 1990s. What are the benefits of using ecowools, what is the field of its application, what is this material about? We will answer all these questions in order within the framework of this publication. In addition, we describe all the options for mounting this remarkable thermal insulation material.

Content

What is ecowool?

80% of the composition of ecowool is taken by natural cellulose. Heat-insulating properties of cellulose are extremely high, and due to their mechanical properties, cellulose easily forms a homogeneous seamless layer.

Cellulose in its pure form in construction works is not used, as it is easily ignited and destroyed under the influence of many biological factors. To eliminate these drawbacks, borax and boric acid are added to the ecowool. Bura plays the role of fire retardant, that is, it prevents the ignition of the material. Due to the use of this substance, the eco-wool is given the degree of fire safety G2. However, it is not used for warming places with high temperatures - chimneys, heating boilers, etc. But for the insulation of the roof, walls, floors between the floors is an excellent material. Due to the use of boric acid, ecowool is practically not affected by the destructive effect of rot, mold and fungi, and rodents do not settle there. It may look a bit strange, but boric acid gives almost one hundred percent protection of the material from rodents, which, as is known, do not disdain to arrange housing even in mineral wool.

If we compare the eco-watt with the usual thermal insulation materials, such as polystyrene or mineral wool, then we will not notice any outstanding thermal insulation or other properties of this material. Ecowool has nothing special about its characteristics, but it is in no way inferior to the "classical" heat insulators. However, this material has a number of unique advantages that make it literally irreplaceable for the insulation of residential buildings.

ecowool: ability to absorb and evaporate moisture

Despite the fact that the ecowool very poorly passes air and moist steam, it is able to absorb a fairly large amount of moisture. But, unlike the same mineral wool, this material absorbs water, and at the same time its thermal insulation characteristics do not deteriorate in any way. So, if the moisture content of mineral wool increases by at least one percent, its thermal conductivity, respectively, grows by 8-9 percent. Ecowool, even with an increase in humidity by 25 percent, begins to conduct heat only 2-3 percent more. Cellulose, which consists of ecowool, is able to absorb and evaporate moisture without any consequences. And if the ecowool is used as a heater for a wooden frame house, the optimal humidity will naturally be maintained inside the living rooms. But to allow moisture to evaporate unhindered, suitable conditions must be created, otherwise the microclimate in the building will be disrupted. Therefore, the ecowool is not used for the warming of the basement floors and basements, that is, places where the humidity level is very high.

integral thermal insulation layer

Ecowool is a loose, homogeneous mass. It can simply be poured into a pre-prepared frame on a wall or floor. As a result - a continuous seamless coating, which, on condition of high-quality work, fills absolutely all the volume intended for it. At the same time, the possibility of forming bridges of cold or voids completely, which can worsen the heat-insulating layer, is completely excluded.

soundproofing properties

As we have already mentioned, this material carries the air quite badly, much worse than mineral wool. But along with this ecowool is very elastic material, and excellently extinguishes any sounds, unlike the same polystyrene. Thus, this material perfectly protects living quarters from external noise.

safety and environmental friendliness of the material

Ecowool does not contain any harmful and toxic substances. As a sticky substance, in the ecowool there is lignin, which does not pose any danger to human health. As for boric acid and borax, these substances are not sprayed or evaporated, so they are also completely safe. Ecowool does not emit absolutely no harmful vapors, in contrast to the widely used expanded polystyrene.

material release form

Looks ecowool, as a heap of cellulosic fibers, representing a loose material. In the industrial installation of ecowool, the material is slightly moistened before spraying, after which it is applied directly to the surface. The material is also used without humidification, pumping it into the frame with the help of a powerful compressor. You can also put the ecowool manually, if it is a question of insulating a small area, for example, a summer cottage or a garage. It will take a little more material and time to work.

Ecowool: mounting technology, wet method

When ecowool is applied in a wet way, lignin is used as an adhesive. Due to this, the eco-wool perfectly sticks to the walls from any material. This creates a layer of insulation, having a density of 50 to 65 kg / m3. Wet method of applying ecowools is perfect for insulation of buildings made of bricks.

To apply a heater you only need to make a crate from a metal profile or wooden bars. Use wood for burrs is preferable, since the heat insulator is better adhered to the wooden surface. After the crate is ready, the material is applied to walls using special equipment. During the work, fluffy ecowool at the outlet of the nozzle is impregnated with a small amount of water and applied under pressure to a heatable surface. A wet method of applying eco-wool has only one significant disadvantage - the need for specialized equipment.

If it is necessary to apply a heater to some complex surface, a suspended structure or a ceiling, an additional glue is added to the water, which together with the lignin ensures a good connection of the material to the surface. This is the so-called wet-adhesive installation of ecowools. The material that favors the battens is neatly cut, dried, after which it can be reused. Thus, the work on the insulation of ecowool is practically non-waste, which can also be attributed to the undoubted advantage of this material.

Dry method of insulation with eco-wool

Cells of the crate, all kinds of niches, holes can be filled with dry material. For this, the eco-wool needs to be slightly swollen. This can be done in a plastic container using an electric drill with a nozzle for mixing the solution. After that the eco-watt simply fall asleep where it is necessary, simultaneously densely ramming.

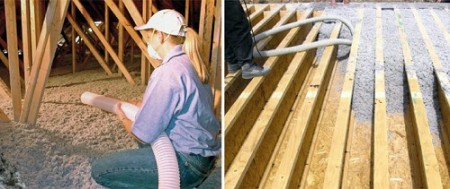

Application of ecowool with the use of a compressor

This industrial method of applying a heater requires the use of a powerful compressor. The coating is completely covered with film or special paper. At the highest point of the battens make a hole in which the supply hose is mounted. The installation of ecowools is carried out by supplying air to the inside of cells, while the material fills everything, even the smallest cavities. After the cell is fully filled, the hole is tightly closed.

Disadvantages when using ecowools

Serious drawbacks of ecowools do not. The only significant disadvantage is the expensive specialized equipment for installing ecowools and the need for skilled workers. Drying ecowool for several days. Wants are not loved by everyone, and someone can attribute such a long period of drying the material to shortcomings.

The result

Based on the above information, we can conclude that ecowool in no way inferior to any other thermal insulation material. Undoubted advantages include environmental friendliness and a long service life of the material. With the help of industrial equipment, you can apply a layer of insulation to a large area of any complexity. When working with ecowool there is no waste, it is a cheap material, it is mounted very quickly. Mounting eco-wool with your own hands is not anything complicated, unless you need a little more material and time. Thus, when warming your house with eco-wool, you will undoubtedly save time and money, and the result will please you for decades.