Finishing work in the apartment can not be imagined without the use of tools. And here to help the home master come spatulas, rollers, soldering irons for PVC pipes and many, many other tools for finishing works. The right choice of finishing tools is the link in the chain "quality of repair."

Content

Tools for finishing works

When carrying out interior works by the home decorator in the apartment, the list of works performed is extensive and includes such types:

• wallpaper gluing

• Facing

• plastering

• Painting.

The list of finishing works can be continued, but this option does not limit the minimum set of tools.

What tools exactly include such a "gentleman's" set?

As the practice of construction and installation works shows, the following traditional tools are used for finishing the room:

• Hook drill, cordless drill, screwdriver

• wire brush and other grinding tools

• Flat spatulas of various sizes from 100 to 500 mm

• Toothed spatulas for tiles and floor coverings

• Circular saw, grinder and grinder

• building measuring instrument

• a set of drills and drills, as well as a bit

• Wallpaper steamer

• level and rule

• rollers and brushes

• Tile cutters

• soldering irons.

Naturally, for carrying out a certain type of work, specific tools are required.

So, for example, for work with gypsum cardboard the necessary set of tools for subsequent finishing can be called:

• building level

• Cutting knife

• Screwdriver or drill

• set of drills and bits

• sandpaper

• putty knife.

And for the installation of suspended ceilings from gypsum board, the presence of electric saw is mandatory. With the use of this tool, with which the cutting of plasterboard slabs and the ceiling finish will be more dynamic. However, how many types of finishing works, there are so many tools that make it possible to comfortably produce a room decoration

With this minimum set of tools, finishing work is done quickly and efficiently. But I always want the finishing tool to have multifunctional characteristics, freeing from routine manual labor.

There are such tools, the universality of which should be emphasized. Such building finishing tools include construction thermofan, plunger pistol and soldering iron for PVC pipes.

Building thermofane - warmer, even warmer

When carrying out finishing works, where it is necessary to use a source of hot air without the use of a construction hair dryer is indispensable. A powerful continuous stream of hot air softens a layer of old varnish and paint, produces processing of wooden parts, produces film welding and soldering of metal.

The appearance of the building thermo-foam is similar to an ordinary hand dryer for drying hair. But the temperature of heating the air jet reaches from 100 to 650 degrees.

The main technical characteristics of a construction hair dryer are:

• operating temperature mode

• power consumption

• airflow.

Thermophanes are equipped with two operating levels of airflow temperature control. These are thermofans with a special electronic system for regulating airflow temperature. The heating temperature is set exactly and automatically maintained the required time. This dynamism is facilitated by the presence of a special built-in temperature sensor and control system.

A building hair dryer is required when performing finishing works when it is necessary to change the structure of the coating or element sharply. The maximum number of working attachments contributes to successful work. It does not hurt to remember that the nozzle of the thermofan and the nozzles cool down to an acceptable temperature after some time after shutdown.

How to choose a building hair dryer will help this video.

Plunger pistol - learn to stick firmly

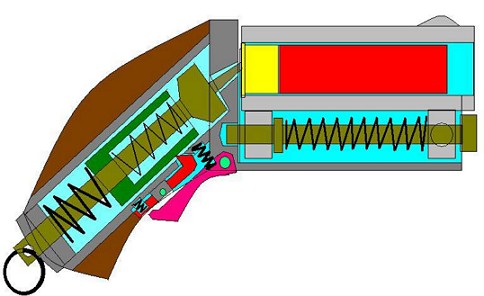

Plunger pistol is designed to supply construction sealants and materials with a significant viscosity coefficient. The smooth and continuous flow of material through the nozzle of the plunger piston, ensures a high-quality application.

Structurally plunger pistol consists of a handle, a cylinder for the mixture and a trigger lever. Ease of use of the tool is provided by a wear-resistant mechanism that includes a coupling, a plunger stem and connecting-rod necks.

The aluminum cylinder for injecting the mixture provides the work of the plunger mechanism without any rest to use the working mixture from the cylinder.

Working with unpainted sealants and materials becomes more economical and profitable. Cylindrical tube is equipped with special fixatives, resistant to various kinds of solvents. Therefore, the process of cleaning the plunger pistol is simple and does not cause changes in the structure of the material.

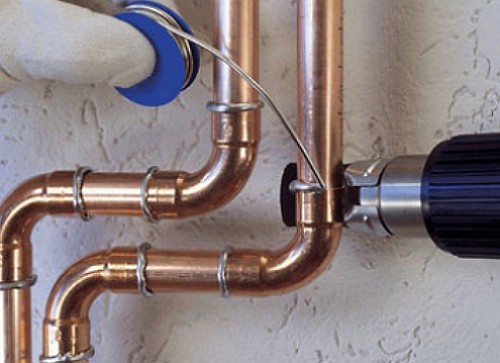

Soldering iron for PVC pipes is a plumber

A soldering iron for plastic pipes is designed for manual contact welding when creating permanent joints. The practice of creating a permanent joint of polypropylene and plastic pipes such as PP-R and PE involves their fusion by heating a special soldering iron into the socket.

The soldering iron for PVC pipes is used by masters for coupler welding and fittings of insignificant diameter up to 63 mm. In this case, the welding force, which carries out welding is insignificant. The presence of a built-in thermostat in the soldering iron allows to regulate the necessary working heating. The main technical characteristics of the soldering iron for pipes are:

• rated continuous operation

• Teflon-coated nozzles

• Presence of a three-mode thermoregulator

• Insufficient heating time

• Ability to work from the network.

In addition to the supply of tools, manufacturers include a metal stand, a Phillips screwdriver and a hex key.

Certainly, any home master strives to acquire a tool with the highest comfort and complete working kit. Therefore, before choosing a finishing tool, it will not hurt to learn more about its capabilities. The received knowledge and reliable information about the subject will create all the necessary prerequisites to become a real right professional Master.