Since ancient times the process of laying pavers was kept in deep secrecy. At work each master used "his" secrets and know-how, laying out with love the mosaic paths in the garden. Useful tips have never hurt anyone, so you should use this information.

Why we choose cobbles

The attractiveness and style of the appearance of the infield area depends largely on how it is designed. Accuracy and cleanliness of the lines of flower beds and lawns excellently emphasize tracks and pavements paved with paving stones.

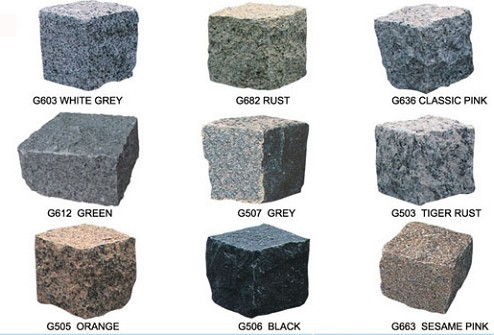

Paving stone make out almost any site, and everywhere it harmoniously fits into the natural landscape of the infield. The atmosphere of luxury is emphasized by the amazing durability of the granite pavers.

By laying pavers in the local area, you can forget about the need to repair or replace the mandatory coverage of the site for a long time. Traditional methods and methods of styling are not a secret. Therefore, you can pave the cover with your own hands, taking into account useful advice from the masters.

Helpful Tips

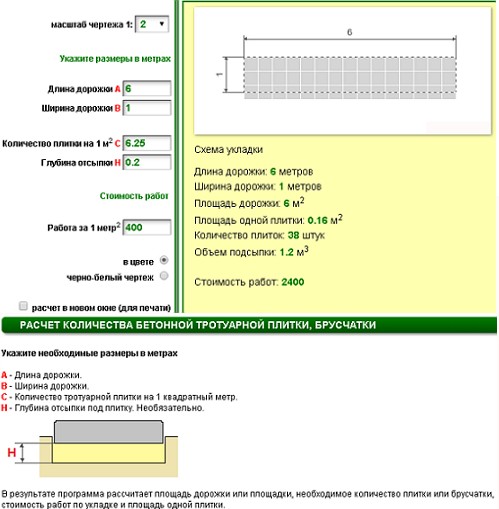

With the use of pavers, the configuration of the coating on the site will not be limited to paths or areas of strict geometric shape. Therefore, we recommend creating a sketch of the location of the cover, which will prompt the appropriateness of the location of tracks and areas. There is a convenient program for calculating the total number of pavers for styling, which can be used on-line.

On the steps of the history of paving stones

Paving stone is a kind of pavement with a hard surface. Cobbles consists of bars of the same shape and size.

The appearance of pavers as cover, we owe to European countries. The first covers of squares and streets from hand-worked cobblestone stones were produced in Europe two centuries ago.

With meticulous precision, slabs from pavers were laid out by masters at the paving of roads, access roads and steps. Borrowed from the picturesque squares of those ancient times, at present the paving stones safely migrated to landscape design, gradually displacing the paths of gravel and stone.

The multifaceted color of small tiles allows creating real works of art. What kind of paving stone is recommended for use in decorating and how to lay paving stones correctly.

Many-faced paving stones

paving

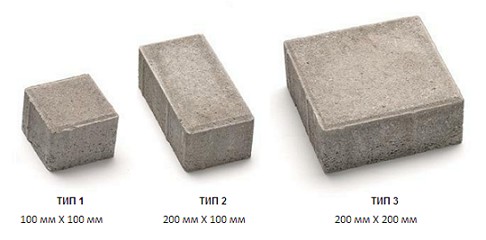

Designers and architects have long dreamed of creating a cover that would embody the quality of the old granite pavers and the style of the pavement. Therefore, the appearance of pavement pavement caused universal admiration and approval. Sidewalk pavers are made in traditional square and rectangular shape, and also in the form of segmented elements that allow to create round ornaments.

In the manufacture of cobblestone paving concrete (M600) is used, which, when vibrated, provides good strength and water resistance, frost resistance up to 300 cycles. Coloring and color saturation of the pavement pavers is retained for a long time.

The rough surface of the pavers is quite convenient for paving garage entrances and rest areas on the site. Let's add that the shape of the paving stone is designed from the viewpoint of ensuring the versatility of the application when laying.

Helpful Tips

Pavement paving is produced by industry of standard sizes: 100x100 mm, 200x200 mm, 300x300 mm. Therefore, there is a great opportunity to create new interesting drawings for styling.

However, there are plenty of options for stacking pavers and you can always choose the right pattern.

clinker

An ideal variant of paving of a personal plot can be called clinker blocks, which have improved performance characteristics and aesthetic requirements. The variability of landscape solutions is considered to be clinker blocks and bricks for lawns. The successful arrangement of pavers of various sizes in one composition allows to "unload" the paving area.

Therefore, for the design of tracks using smaller pieces of pavement blocks than for sites with traffic load. The most common type of clinker coating is a rectangular brick of standard size 100x200 mm.

Such a brick, thanks to the correct geometric shape when laying, leaves virtually no waste. Several rounded edges of the tiles during laying create an interstitial space through which rainwater or melt water freely flows into the soil. The coating from the clinker paving stones looks fresh and clean.

How to lay sidewalk paving stones

The process of laying pavement paving stone paving is painstaking and lengthy, requiring "perseverance", because the tiles must be laid on their knees. The sequence of technology consists of the following stages:

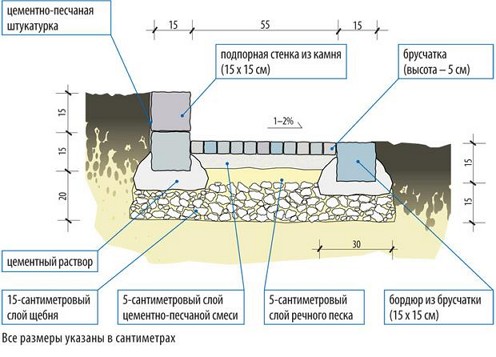

- preparatory (marking the plot and the base of the site) with a padding of the leveling layer 5 cm.

- laying of prepared tiles

- tamping of laid tiles

- grouting

- stripping of the laid coating

foundation preparation

The paving stone should be laid on a level platform, so for the marking, hammer the pegs, pull the rope and conditionally specify the direction of water drainage. Do a sanding of the leveling layer with a thickness of 5 cm. The leveling undercoat neutralizes the difference in the thickness of the tile to be laid. Level the site with a rod and pour abundantly with water.

laying of working tiles

We prepare a dry working mix for packing from sand and cement.

Lining undercoat - garnovka is a dry mixture consisting of six parts of sand and one part of cement.

On the basis of a dry mixture is recommended to spread out as you install the next row of pavers. Cobbles are laid in the direction from the edge to the center, each time checking the level of masonry. When laying a complex colored ornament, paving stones are taken from several pallets.

The position of each brick pavers as they are installed are pummeled with a rubber mallet. After laying the whole field, a tamping of the laid tiles is made. For this purpose it is recommended to use mechanical tampers.

Helpful Tips

It is recommended to place shaped pavement elements 1 cm above the marked level of paving. This stock must be adhered to, because when tamping (one or two passes), the paving stone will settle on such a thickness.

tamped pavers

Having finished the laying of pavers, we make the tamping of the mounted covering. For this purpose, an electric, diesel or gasoline plate compactor is used. The vibration plate sole should be equipped with a rubber pad, which excludes any damage to the face layer of the coating. Passages, and there may be several, are carried out until the paving stones completely shrink into the leveling layer.

grouting

After one or two passes, dry sand or fine gravel must be spread over the surface of the coating, which is distributed at the seams of the stone blocks until the joints are completely filled. The final stage of stacking pavers is the cleaning of the laid coating with a brush.

Learn more about the intricacies and secrets of laying pavers in this video.