When the house is built, it is necessary to move to its interior decoration. The first step is to make the floors. Most prefer wooden floors. They are rather easily and quickly installed and do not weight the construction of the house, unlike concrete slabs. In this article, we will tell you how to arrange wooden floors and properly align them.

Content

The device of a floor in the wooden house

The tree is the most environmentally friendly and optimal choice for flooring in a wooden house. The floor is the uppermost part of the exploitable floor. All the floors in the house can be divided into the following types:

- socle;

- inter-floor;

- mansard;

- attic.

Also, floors must meet the following requirements:

- be stiff and not sag;

- simplicity of installation.

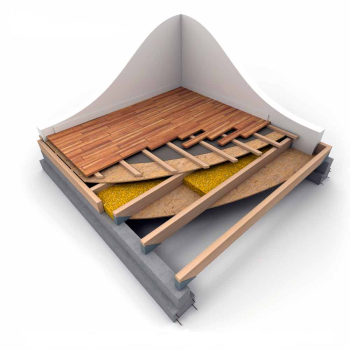

Each type of overlap is experiencing a certain burden from standing on it furniture or other items. Therefore for each room it is necessary to take into account the degree of loading on the surface. By methods of installation, the floor can be divided into two types:

- mounting on logs;

- installation on wooden beams.

the device of a wooden floor on logs

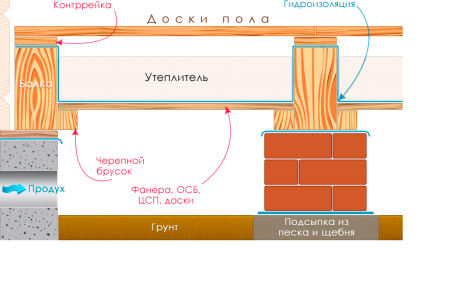

When you build a floor, lags can be placed on a concrete base. Lags can be laid on a special substrate, but it must be taken into account that over time it can deform or shrink. As a result, the floors can creak or deform. Also, the logs can be laid on a cement screed that has leveled the surface. Such a floor will be smooth and durable. Before laying the log on the concrete, you need to do the following:

- conduct waterproofing of the base (concrete is a hygroscopic material), for these purposes polyethylene film is excellent;

- lay sound and waterproofing;

- the floor is cemented with cement.

It is also possible to lay logs on the ground. For this, the surface is carefully tamped. After that, make measurements, and install columns for logs. They need to be covered with waterproofing, to prevent wetting boards. After installing the lag you need to conduct a thermal insulation of the floor. Warming can be any material convenient for you (mineral wool, expanded polystyrene, etc.). A heater is laid in the distance between the lags. If they are on the ground, then the layer of heat-insulating material is put on the rough floor. Laying floor boards usually start from the far corner of the room, gradually moving to the door. The first row should be laid at a distance of 1 cm from the wall, this will compensate for the expansion of the tree during operation. Then fix the screws. If the length of the board is less than the length of the room, the next rows must be stacked with offset. The boards must be inserted in the grooves of the previous row. All the rows of material are laid tightly to each other. The last row is well fixed with screws, taking into account that they will be covered with a plinth. The wooden floor on the logs is easy to install and durable, so it is popular.

device log

Lags are cross beams, on which the installation of the floor itself takes place. They are boards, they can be metal, wooden or reinforced concrete. When installing the floor on logs, there are a number of advantages:

- improvement of noise insulation;

- optimal load distribution;

- presence of underground in which it is possible to lay engineering communications;

- better thermal insulation of the floor;

- strength;

- good access to replace individual items in case of damage.

For logs most often choose quite inexpensive wood: pine, spruce. The least likely is the choice of larch due to its high cost. It is also not necessary to choose the material of the highest grade, 3 or 3 sorts of wood are quite suitable. It is better to use boards of rectangular section, and the height should be twice the width. This size of the log will ensure high reliability of the floor. Also, it is necessary to select wood with a moisture content of not more than 12%, and it is also necessary to inspect the material for defects. They will not contribute to the evenness and reliability of the floor.

floor installation on wooden beams

When you can not put the floor on the lags, it remains to mount it on the beams. They are an integral part of the design of the house and make up its frame. Therefore, the floor on the beams will give the structure additional strength. This method of flooring has a drawback. It is that any impact on the surface of the floor is transferred to the walls and supporting structures of the house. Therefore, before installing the floor on the beams, you need to build an additional frame. But this kind of installation of the coating has the following advantages:

- small installation costs for the lower floor;

- light weight of the whole structure.

Consider step-by-step how to fix the floor to the beams:

- On both sides of each beam are installed bars, to which without gaps we attach the flooring. For these purposes, you can use different materials: gypsum board, boards, particle boards, etc. As a result, the flooring in the lower cleaning of the beams will be made.

- Afterwards, on the surface of the floor, we are waterproofing for the safety of the structure.

- We conduct the insulation of the received space between the beams. This can be done as specially provided for this purpose materials (mineral wool, polystyrene), and simply fall asleep with sawdust or expanded clay.

- After carrying out the preparatory work we lay the floor itself. It should be made of boards with a thickness of at least 35 mm. On the beams, you can lay logs, and on top of them to cover the plated coating. This will provide additional ventilation to the entire floor.

This process is not complicated enough. To install the floor on the beams do not need to spend a lot of effort, time and money. With this work even a person far from construction can cope.

Wooden floor installation

It is best to install the floor at the end of the heating season. This is directly related to the humidity of the wood, the boards will not break from the excess moisture. If the summer is in the yard, and the floor needs to be sheltered, wait for stable sunny weather. Before starting the installation, treat the boards with special antiseptics. This will protect your sex from rotting and spoiling it with insects. For flooring wooden floor can come up:

- the board is not edging;

- various sheet materials (OSB, chipboard, plywood);

- board made of laminated veneer lumber;

- processed board.

The first two types of materials are suitable for the device roughing floor, which then put the final coating. The latest materials are used to install the finishing floor. They can be painted or varnished. The boards are best to match the width of the room. Most often used material of coniferous wood: pine, cedar or larch. Very rarely the floor is made of hardwood.

Leveling the wooden floor

The wooden floor is very beautiful. But over time, the tree can crack, and the floors begin to creak and sag under the load. For the flooring to last a long time and do not cause trouble, it should be leveled. How to do it now tell. When aligning, the first thing to do is to determine the height differences. For this you can use both laser and water level. With a laser level, it is quite easy to determine the difference. If you have a water model, it is better to take it 2 m long. Then we start measuring the entire floor in the room and marking the walls. If the resulting drop is 1 mm, then the floor can be considered absolutely flat. If the difference is 1 - 3 mm, it can be easily corrected by mixtures to level the wooden floor and remove the boards, and sanding them in place. At large differences, it is necessary to level the floor with plywood. It's fast and simple enough. The alignment of the floor is as follows:

- it is necessary to measure the dimensions of the room, and cut the plywood sheets according to the dimensions (it is necessary to take into account the gaps from the walls of 1 cm and between the sheets of material 5 mm);

- after it is necessary to install logs 3 - 4 cm wide by means of glue or screws;

- after that, we mount the plywood sheets on the prepared surface and fix it with dowels or screws.

Remember to treat the material with antiseptics. Also, plywood can burst with fasteners, so it is necessary to pre-drill holes for fastening.

The cost of wooden flooring

When installing the floor, you can hire specialists. Then the square meter of floor you will cost 1400 rubles. This includes:

- concrete screed;

- installing the lag;

- flooring boards;

- the installation of plinths.

You can do everything yourself. To do this, you need to purchase floor lags. The average cost of one cubic meter is 7000 rubles. Also, the sex boards will need prices, which range from 550 to 2500 rubles on average. Also you will need waterproofing on average 1000 rubles for 15 kg of mastic, and thermal insulation from 500 to 4000 rubles per packing, depending on the material. In this case, you do not have to pay for the work and you will be able to fully control the process. In any case, independent installation of the floor will cost less than hiring workers.

This article describes the types of wooden flooring. Tips are given for laying and leveling the surface. Also, an approximate calculation of the cost of self-installation of the coating and recruitment of specialists is given. Thanks to the advice of the article, you can easily select the best option for a floor device, easily pick up materials and arrange a wooden floor in your home. Good luck in your endeavors.