Warming of the outer walls of a residential building is the main and the most correct way to keep heat in the dwelling and save considerably on heating. The benefits of warming the building are obvious, and we will not consider them. No less important is another question: which heat-insulation material is better to use, what tools and devices are needed for work? For work at height, you must have scaffolding. We advise you to use the services of a specialized company and rent used scaffolding. So you will solve an important problem and save your finances. And the most popular thermal insulating materials today are mineral wool and polystyrene foam. We will talk about the advantages and disadvantages of these materials, and in passing we will try to answer the question: what is better - polystyrene or glass wool?

Content

Styrofoam, or expanded polystyrene

A very popular thermal insulation material, it is used everywhere in private and mass construction. Polyfoam consists of small balls, inside of each of which are thousands of microscopic cells filled with air. Cells are hermetically sealed, and air can not move. This explains the excellent thermal insulation performance of the foam. Strictly speaking, this material consists of air at 98%. Hence one of its main advantages is its low weight.

Polyfoam - which is better?

Manufacturers produce a foam of different density. The higher the density - the worse the thermal insulation properties, but the higher the resistance to mechanical stress. As a heater, plates of foam of different density are used. Polyfoam with minimal strength characteristics in the process of building insulation should be protected from mechanical damage as much as possible. A plate with a low density is most often used with a wireframe method of installation, when the maximum load falls on the frame.

Where is the foam used as a heat insulator

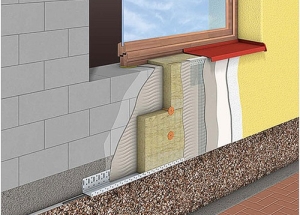

As a thermal insulator, this material is used for the insulation of facades, exterior walls, attics, cellars, floors, foundations. Sometimes foam plastic insulate the internal parts of the walls, which should not be done for the reason that the foam-coated interior wall will be poorly warmed. As a result, the "dew point" is displaced inside the wall, moisture begins to condense there. This can lead not only to a violation of heat exchange, but also to premature destruction of the wall itself.

Therefore, if you decide to stop your choice on a foam plastic, it is better to use it solely for exterior decoration. But it must be remembered that this material, even having the maximum density, is extremely unstable to mechanical damage. Because of this, it becomes necessary to strengthen the outer surface of the foam board. You can do this with plaster or reinforcing mesh.

In the case when the foundation is warmed with the help of foam plastic, it must be protected not only from the external pressure of the soil, but also from the loads that occur in winter, when the soils are frosty. Grid or plaster here does not help, you need to protect more seriously, at least - brickwork or wooden formwork.

advantages of foam plastic

- This material is not afraid of moisture and does not absorb it.

- Excellent thermal insulation properties.

- No mold and fungi on the surface.

- Light weight.

- Cheapness.

- Resistance to temperature changes.

- There is no need to install waterproofing.

- Simplicity and ease of installation.

disadvantages of foam plastic

- Very poor resistance to mechanical damage.

- Poor air flow.

- Instantly destroyed from exposure to paintwork and solvents.

Mineral wool

Minvata is a heat-insulating material, no less common and popular than polystyrene. Depending on the raw materials used in production, mineral wool is of the following types:

- Glass wool. In the production of the material, a glass melt is used.

- Stone wool - used rocks, a product of volcanic eruptions.

- Slag - is made from slag - waste of blast furnaces.

Plates of mineral wool can have a different structure of fibers. This is due to technological features of production. Vata can be horizontally-layered, vertically-layered, spatial or corrugated. This feature greatly expands the range of application of this material in construction.

Which minvata is better?

There is no unambiguous answer to this question, since everything depends on the purpose for which the material will be used and under what conditions. For example, to insulate a roof with an even surface, rigid boards with a horizontal fiber structure are best suited. If the roof is pitched, then plates with a spatial structure are used, which give a good bias. Answering the question "What is the best mineral for the walls?" It is necessary to consider which parts of the walls will be insulated - external or internal? For external insulation, a two-layer stone wool slab with a hard top layer is well suited - it protects the plate well from deformation, and provides a flat surface. For internal insulation, soft glass wool sheets are suitable. Mount them best in the framework of the profile, which is later attached sheets of drywall or other finishing material.

Where mineral wool is used

Minvata is very resistant to high temperatures and various aggressive environments, excellent sound insulation and thermal insulation characteristics. Therefore, today it is produced quite a lot. Minvata is successfully used for heat and sound insulation of walls, ceilings, various fences, as a soundproof material for acoustic screens, as protection against fire, etc. In addition, mineral wool is insulated by surfaces that have a very high temperature - heating mains, pipelines, furnaces, etc.

advantages of mineral wool

- Excellent thermal insulation properties.

- Resistance to high temperatures, incombustibility.

- Resistance to mechanical influences.

- Tensile strength.

- Excellent soundproof performance.

- Easy to install.

- The material does not deform when temperature changes occur.

disadvantages of mineral wool

- The material is unpleasant for the skin, harmful to the eyes, lungs.

- If phenol-formaldehyde resins were used in the production process, it is harmful to health.

- Minvata with low density will eventually shrink.

- Needs waterproofing.

- High, in comparison with polystyrene, the price.

In conclusion, we note - the debate on the topic "What is better - polystyrene or mineral wool?" Have been conducted for a long time, and no unequivocal answer has been received. Polyfoam and mineral wool are materials with completely different characteristics, and each of them can be an ideal option in this or that situation.