Many would like the summer period to last as long as possible, but it's hard to argue with nature, it's impossible to avoid the cold season in our localities. Every home owner starts to think about how to warm your house, at the same time spending a minimum of money. Modern developments in this area are not standing still. Firms engaged in the development of this industry create a variety of heating equipment, which allows using not expensive natural materials (coal, gas, etc.) as fuel, but other raw materials that comply with environmental standards. One of the most striking examples of such equipment can be rightfully considered pellets on pellets. European countries have long used such equipment.

Content

What is a pellet boiler?

Pellet boilers, first of all, are economical sources of heating. They can be arranged in different ways: either as a separately functioning equipment or as equipment with an integrated structure. A boiler of this kind can heat both a single room and housing in general.

In order to heat the adjoining rooms from a single pellet boiler, a ventilation duct system or ordinary ventilation openings are used. In such cases, do not worry about the possible difference in temperatures between rooms, it will be very small and will not have a negative effect on the comfort of the people in the rooms.

Heating systems running on water, gas or electricity, today are at the peak of their potential capabilities for efficiency. In addition, the use of heating systems of this kind, in remote settlements or cottages located far from gas mains, is not always available and is often very problematic.

Comparing practical and economic resources, users are increasingly choosing to use pellet boilers.

Pellet heating boilers

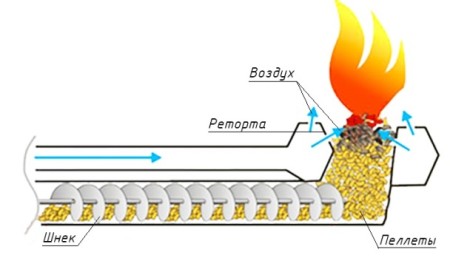

The principle of operation of such a boiler is based on the relationship of the following departments:

- chamber in which combustion takes place,

- receiver in which pellets are placed,

- automated system.

Fuel in solid form, that is, pellets, first enter the receiver, and then into the combustion chamber. Once the pellet pellets are in the chamber, an automatic ignition occurs, which contributes to the further complete combustion of the fuel material.

Translated from English, Pellet's are pellets made of wood and intended for use in heating systems of a certain type. From the waste wood (sawdust) under high pressure, small cylinders, that is, pellets, are formed. The production of this type of material occurs without the addition of any harmful, chemical substances.

The heat output of 1 kg of pellets is 5 kW / h, and the heat produced is environmentally friendly, that is, it is absolutely harmless to humans, animals and the environment. For comparison: the same amount of kW / h is obtained after burning 0.5 liters of diesel fuel.

Compared with the usual wood, the efficiency of burning pellets is much higher. Pellets occupy much less area for storage, because it is denser. In addition to everything else, pellets can not accidentally ignite. It should also be added that when burning pellets, much less CO2 is released than when burning coal, and hence the greenhouse effect is reduced.

Cleaning of the boiler from the ash is not performed more than once a week, the chimney must be cleaned at least once a year. It turns out that caring for heating units is very simple and does not take much time from owners of the house.

Automatic pellet boiler - the reasons for the popularity of heating units of this type

The first and most important reason for the popularity is the very high efficiency of the boiler, if wood with an open flame allows an efficiency of 35%, then the mass of pellets corresponding to it by mass will give an efficiency of about 85%. If the pellet stove is equipped with an additional water circuit designed to supply hot water to the bathroom and the kitchen, the efficiency can increase to 93%.

For the storage of pellets a special bunker is used, the pellets from it to the boiler furnace are fully automated. The program is set by the consumer for a whole week. In accordance with the program, the ignition is switched on at the set time. To the arrival of the owners, the air temperature in the house will reach optimal values. For a given temperature regime in the room, the pellet boilers independently increase or decrease the combustion activity independently and, if necessary, their operation can be controlled by means of a remote control.

A medium-sized boiler uses about 5 kg of fuel per day, the average size of the pellet hopper allows continuous use of the boiler for 3 days without adding fuel.

If necessary, a larger plastic hopper or a box constructed of metal corners trimmed with plywood sheets is installed in the room. If the loading and unloading of the plastic bag with pellets was carried out neatly, if desired, big-bag can also be used as a storage facility, the package can hold up to 800 kg of pellets. Load the external hopper from the outside of the room, i.e. There is no need to carry pellets around the house.

The operation of the boiler is monitored by an automatic control system, since not more than a handful of fuel can be in the boiler burner at the same time, the device overheating is completely excluded. The complete cessation of burning occurs 5-10 minutes after the deactivation button is pressed.

When the pellet boiler is operating, the oxygen burn-out process is completely eliminated - the combustion air supply circuits and the heating circuits are divided among themselves. Some users go for small tricks and draw air from the basement - this allows you to dry and ventilate the basement without using additional energy resources.

In addition to the above:

- the pellet boiler is equipped with a noiseless fan, which makes it possible to obtain an even circulation of air,

- the release of combustion products during the operation of the boiler is minimized, even if we compare pellets and the highest quality wood, the first leaves after combustion twice less ash and soot,

- when the boiler operates, its housing does not heat up, the entire system works to heat the air, the unit poses no danger to nearby people and animals,

- the presence of a timer, thermostat or intelligent control system system allows to ensure continuous safe operation of the boiler,

- the buyer has the choice of a system for supplying fuel to the boiler (auger, pneumatic and other systems),

- to the dimensions of the boiler room, special requirements are not imposed.

The advantages and disadvantages of boilers can be found in more detail from the video:

Among the shortcomings that distinguish pellet heating should be remembered:

- the cost of pellets, which still exceeds the cost of conventional firewood, although the increase in convenience for the user is always associated with some increase in costs,

- storage of pellets should be carried out in a dry room,

- relatively high for today is the cost of the boiler itself,

- the consumption of funds for the purchase of pellets in the heating season will amount to an amount exceeding the cost of natural gas spent for heating the same premises, but taking into account the stable growth of energy prices, it can be assumed that in the near future interest in pellet boilers will increase.

Safety of operation, environmental friendliness and long service life have already led pellet boilers to the first place in the market of alternative heating systems.

What are the characteristics to pay attention to when choosing a pellet boiler

To select the optimal boiler model, experts recommend taking the following into account. Boilers are produced with type spirit burners.

The retorts do not require frequent cleaning, they are not so demanding for the quality of pellets, the flame from them is released upwards.

Stockers can work only on clean, low-ash fuel, their burners are often clogged and require systematic cleaning, the flame emanating from them horizontally. Consequently, appliances with retort heaters are more practical.

Automation level Pellet boilers may have a different degree of complexity, especially those equipped with the function of control via SMS messages, i.e. a person has the ability to remotely control the device's turning on and off, adjust its temperature, etc.

An additional advantage is the warning of the owner about the emergence of a critical or emergency situation in the operation of the heating device.

Screw, which are equipped with boilers can be flexible or rigid.

The latter is attractive for low cost and simple construction, but it has limitations in length - 1,5-2 m, it is impossible to change its position relative to the burner, eventually it leads to irrational use of the area. A flexible screw system allows the hopper to be installed at a distance of up to 12 m, and the fuel supply line can have any geometry.

Complexity is caused by the fastening system of a flexible structure. When choosing, it is necessary to determine what is more important: ensuring the reliability of the feed or the possibility of creating a longer line.

Heat Exchangers for pellet aggregates can have a vertical, horizontal, flat or tubular structure, they can be equipped with turbulators, have a different number of turns and turns. According to experts, the devices with two or three strokes equipped with a turbulator are most effective.

It is important to consider the reliability of the design, it is safer to buy models that have been on sale for several years and received positive feedback from users. It is also desirable to make sure availability of spare parts for this type of equipment - it is difficult to guarantee that in the coming years no replacement of any unit will be required. The device must be serviced by a qualified technician.

Pellet boiler installation

Among the important advantages of aggregates working on pellets should be attributed the possibility of installing them yourself. This can be done even by those who do not have experience in performing complex assembly works. Moreover, the installation of a heating device of this type does not require obtaining special permits.

Rules of maintenance and installation of pellet boilers, after completion of which no alterations or other additional actions are required:

- installation of the boiler is best done in a separate room from the dwelling (cellar, extension and the like),

- floor, in the room where the installation of the boiler is planned, should be made of ceramic tiles or concrete,

- the location of the boiler must be thought out so that it is possible without problem to clean, repair or care for it,

- the front wall of the boiler should be at a distance of not less than 1 meter from the wall opposite,

- the temperature regime in the room with the boiler should not be lower than +10 degrees, while the humidity should be within the limits of the norm,

- in accordance with the technical characteristics of the boiler, it is necessary to equip the hood and ventilation system in a room intended for heating equipment.

Stages of installation:

- Installation of the unit should begin with the design of the heating system, a professional approach to solving this issue will ensure its effective operation.

- The preparation of the premises will consist in erection of the podium, installation of ventilation and smoke extraction systems.

- If the unit is not equipped with a bunker, then it will be necessary to think and carry out the assembly and installation of a suitable size structure.

- After installation of the boiler on the podium, the piping systems of hot water supply and heating are connected to the unit.

- Then connect the chimney and perform commissioning.