Manufacturing technologies do not stand still and help to build warm houses in a short time. Today, aerocrete blocks are very popular. They have different sizes, weigh less than ordinary bricks. Build a building from them easily and quickly. How large are aerated concrete blocks, how to build a house from them in this article.

Content

Cost of aerated concrete

Aerated concrete is a modern material that is obtained by mixing concrete, sand and gas generators. Due to this composition, the blocks have low weight and excellent thermal insulation properties. The cost of wall blocks starts from 3000 rubles per cubic meter. m. Partition walls cost a little more, for a cube. m will have to pay 3200 rubles. Blocks for formwork are sold per piece and their price starts from 360 rubles per unit. These are quite reasonable prices. And if you take into account the gas block has dimensions several times greater than the usual brick, this will help to save on construction materials. Also for laying you will need a special glue, which costs from 205 rubles per 25 kg package. For the erection of a full-fledged house, the costs for aerated concrete blocks will be less than for conventional bricks.

Construction of a house made of aerated concrete

So you are ready to start building a house. The site has already been cleared and fully prepared, the necessary material has been purchased. Where do you need to start work? Of course from the foundation. It is a very common misconception that this material is easy and does not need a solid foundation. This is not so, because aerated concrete is very vulnerable to bending deformations. Just the foundation can be done different. The best option to fill in monolithic plate the size of the house. Such a foundation is resistant to soil subsidence. The best thickness for this option is 40 cm, and most of it should protrude above the ground. For the construction of such a foundation it is necessary to install the formwork and to lay the waterproofing. After which the reinforcing mesh is laid, the concrete is poured in several stages in layers of about 15 cm. After the concrete has risen the formwork is removed and the gaps between the slab and the foundation pit are covered with soil.

You can also make the following types of foundation:

Band monolithic. For him, dig a trench (depth of 50 cm) along the perimeter of the future house, make a sand pillow and install the formwork. Then, in the cavity of the formwork, the associated reinforcement is laid and then the concrete is poured. All work is recommended to conduct in the warm period of the year, to prevent freezing of the soil. If you polaniruete to arrange a basement foundation must be damped to the required depth.

Column foundation. It is a pole installed in the places of greatest load, in the corners of the house and in the places of future intersections of the walls. It is recommended to install poles every 1.5 m and the depth of their installation should be 30 cm below the freezing point of the soil. All supports must be strictly vertical. After that, the space between the pillars is covered with a mixture of sand and gravel and filled with concrete, with or without reinforcement. This variant of the basement is suitable for a house without basements.

After the foundation is ready you can start building the walls. For external walls it is best to use blocks with a thickness from 375 to 400 mm, for the device of interior partitions gas blocks for more than 250 mm are suitable. Also in the clutch will help a special tool. We proceed to laying. First, we put a roofing material on the foundation along the perimeter of the walls. After that, we apply the cement mortar and lay the blocks. It must be carefully monitored so that the surface is level, on this depends not only the convenience of further masonry, but also the strength of the structure. Also blocks can be stacked on a special glue. Its consistency should be similar to thick sour cream. It is necessary to put the following rows from the corners of the house. If you plan to build a two-story house you will need U-shaped blocks. They are necessary for the device of door and window apertures, and for installations of beams of overlapping. These jumpers are installed along the perimeter of the walls and filled with reinforcement for rigidity. In places of apertures it is necessary to establish props. Then pour concrete. After its solidification, a monolithic belt around the perimeter of the house is formed. Now you can put beams overlapping, and erect the second floor. As overlapping, it is possible to use aerated concrete slabs or to make an ordinary wooden floor on load-bearing beams.

After the completion of the construction of the walls, cover the roof and proceed to finishing works. In principle, the construction of a house made of aerated concrete blocks does not differ from the construction of a brick house, and will not cause any special difficulties.

Aerated concrete blocks

Recently, aerated concrete has become very popular with the construction of private houses. Of course, like any other kind of building materials, it has advantages and disadvantages. The positive features of aerated concrete include:

- Good strength. Achieved by making blocks under high pressure and temperature.

- Light weight. This allows you to reduce the cost of the foundation, and the purchase of material.

- High heat and soundproof performance. In the finish it is not necessary to provide additional insulation and sound insulation.

- Resistant to low temperatures.

- Good to be cut, sawed.

- Is safe for human health.

The disadvantages include the need for exterior decoration. Aerated porous material and atmospheric precipitation falling on it will leave dark spots on the facade of the house. Over time, it will grow mosses and lichens. This will not look very aesthetic at all, so the building needs to be bricked or simply plastered.

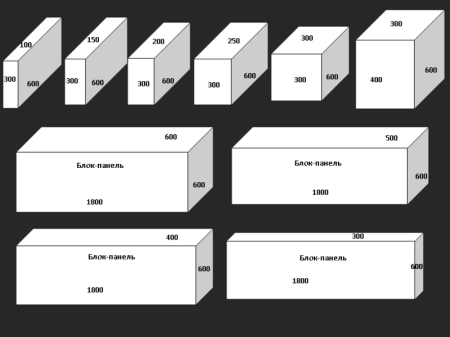

Aerated concrete blocks dimensions

Blocks of aerated concrete, like brick, can have different sizes. There are three types of blocks:

- walled;

- for partitions;

- U - shaped (necessary for formwork).

Accordingly, they have different sizes. The first have the following dimensions:

- length 600 mm;

- width 250 - 500 mm;

- height 200 - 250 mm.

The interior walls of the house do not make it too thick, it's no good. Therefore, the partition walls have the following dimensions:

- length 600 mm;

- width 100 - 150 mm;

- height 200 - 250 mm.

For the arrangement of door and window openings, blocks with a recess in the middle for casting a concrete belt are used. Such a block has the size:

- length 600 mm;

- width 300 - 500 mm;

- height 200 - 250 mm.

Dimensions are very diverse and everyone will be able to pick up the material of the necessary dimensions.

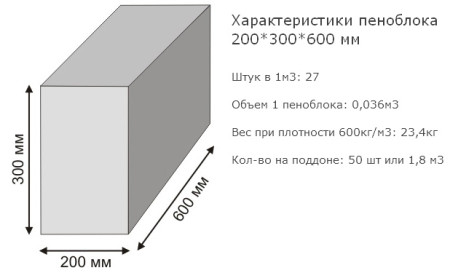

How many blocks are in the cube of aerated concrete

Of course, the material for building walls is convenient to buy a cube. meters. So you do not have to buy blocks if there is a shortage, and the construction will go faster. The number of blocks per cubic meter directly depends on their size. It can be calculated by simple mathematical calculations. First, you need to measure the volume of the block. To do this, multiply all its parameters, first translating them into meters. For example, 0.6 * 0.3 * 0.25 = 0.045 cubic meters. After this, 1 cu. m divided by the number obtained. As a result, we get: 1 / 0.045 = 22.22222 pieces. Rounded, we get that in 1 cu. m is 22 blocks. Now on the sites of the producers of the material the data on the number of aerated concrete blocks of different sizes in one cubic meter are given. Knowing the exact figure, you can easily count the number of blocks on your house. To do this, you need to find the volume of the wall, multiplying its height, length and thickness. Then multiply the resulting number by the number of blocks per cube. m. The obtained value and will be equal to the amount of material for one wall.

Bricklaying of aerated concrete

If you know all the nuances of laying aerocrete blocks, you can easily build a garage or a house from them. You need the following tools to work:

- level;

- a cord for marking;

- mallet;

- hacksaw and plane for aerated concrete;

- shtroborez;

- armature;

- brush for removing dust from depressions.

Then it is necessary to prepare a cement mixture or special glue. Now you can start building. The first row is fixed to the cement mixture, the thickness of which should be 2 cm. Using the level, we check whether the blocks are evenly laid. After the end of the first row, it is necessary to fasten the cord, which will serve as a guide for the subsequent rows. To adjust the blocks it is necessary to use a kyanite. Each row must be sanded for smoothness of the next layer of blocks. It should also be remembered that the blocks should be placed with a displacement of 8 cm or more for the greatest strength of the structure. Also the guarantor of the strength of the house is the reinforcement of the walls. Every four rows in blocks it is necessary to make grooves 4 cm wide, retreating from the edges of 6 cm. After that, the bars of the reinforcement are placed in them and filled with special glue or cement mixture. Next, the following rows are laid. The technology of construction from aerated concrete is pretty simple. Therefore, for construction, it is not necessary to resort to the help of specialists, it is quite possible to manage on their own.

Aerated concrete with own hands

It is not necessary to buy the material in the construction markets or to order from the manufacturer. You can make blocks in the home. To do this, you need:

- concrete mixer;

- forms;

- wire.

With these tools, you can go on to make a solution. To do this, you need:

- cement;

- quartz sand;

- quicklime,

- caustic soda or sodium sulfate.

Mix components in small increments, gradually adding components. Everything must be thoroughly mixed, it is easy to achieve this by means of a concrete mixer. After that, the resulting mixture should be poured into molds. After the filled molds stand a little to the wire, level the surface, cutting off the irregularities. After that, the solution remains in the form of about 20-24 hours. Of course, this technology has drawbacks, the quality will be inferior to the production counterparts. Although it will be cheaper to purchase material from the manufacturer. Do the blocks yourself or acquire their personal business. Although the technology of independent production is not so complicated.

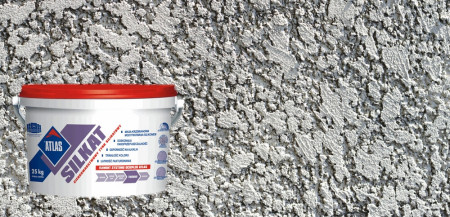

Plaster for aerated concrete

Inside the blocks of aerated concrete there are many voids due to which it absorbs moisture well. Therefore, exterior decoration of the building is simply necessary. Plaster walls from aerated concrete are better after some time, so that they are well dried. Not all finishing materials are suitable for blocks. Now in the market special plasters are presented, which will perfectly lay down and form a protective layer on the wall made of aerated concrete blocks. Let us consider these materials in more detail:

Lime - sand mixture suitable for manual finishing. It is sold in packages of 25 kg. Has a grain of 1 mm. The packaging of this material will cost an average of 265 rubles.

Acrylic plaster. Suitable for more decorative home decoration. However, according to the parameters of vapor permeability, they are inferior to sandy lime mixtures. The cost of 25 kg is an average of 2000 rubles.

Silicate plaster. Provides good vapor permeability and low absorption of moisture into the walls. The disadvantage is a small selection of colors. Its cost is comparable to acrylic analogs and is equal to 2000 rubles.

Silicone plaster. Creates a durable coating that is resistant to rainfall. For a long time keeps an attractive appearance. The price of this plaster varies from 1700 to 3200 rubles.

The assortment of plaster is very diverse and everyone will be able to choose a mixture with the necessary physical properties and attractive appearance.

This article tells about gas-concrete blocks. It tells about their size. Using the advice of the article, you can independently calculate the number of blocks and build a house. If necessary, you can independently manufacture aerated concrete. It is also easy to pick up plaster for exterior wall finishing. Successful construction.