The popularity of wood in the field of low-rise construction has increased dramatically, especially in the construction of country houses, cottages and cottages. Within the framework of this publication we will tell you what types of wood are used in construction, consider the advantages and disadvantages that a tree has as a building material, and much more.

Content

Types of wood

To solve various tasks in construction, one or another type of wood is used, convenience in purchasing, for example http://bistrend69.ru/doska_brus.php, where there is a great choice.

All breeds are divided into deciduous and coniferous. The latter have a sharp resin smell and have a pronounced macrostructure. The most common industrial breeds of coniferous wood are pine, fir, spruce, larch and cedar.

Most often in the construction of pine.

The color of its wood varies from pale yellow to reddish-yellow.

Pine is an easy and durable material, simple and easy to handle. Pine wood contains a large amount of resin, so it perfectly resists rot and moisture. Thanks to its soft structure, it absorbs paint and lacquer well. Pine almost does not warp when drying. Of the shortcomings of this wood, it should be noted only the impossibility of high-quality finishing and coloring of the surface.

Next, according to popularity, there is a spruce.

Its wood contains little resin, so it is more prone to rot and moisture. Spruce - a strong and light material, but very gnarled, which significantly reduces its quality and cost compared to pine. Of the advantages of this material, it is necessary to note a pleasant light color and low resin content. Well holds all sorts of fasteners - bolts, screws, screws, etc. In construction, it is used to make parts of secondary importance.

Cedar, or Siberian pine.

Cedar wood, although soft, but very dense, is resistant to decay, perfectly treatable, in which it is much superior to spruce.

Fir in its characteristics is not much different from spruce: it is well processed and does not tolerate corrosive chemical compounds.

Fir wood contains little resin, which makes it quickly rot without proper treatment.

Larch wood is valued, in the first place, for strength, hardness and resistance to decay. Larch is so dense and hard material that it sinks in water.

As for hardwoods, they are divided into soft and hard. Wood of hardwoods practically has no smell, the material smells only after a fresh cut. Hardwoods used in construction include: oak, ash, birch. Soft breeds: aspen, alder, linden.

Oak - very durable and resistant to putrefactive material, has a very beautiful texture and has a pleasant color.

Oak is widely used for furniture, art and luxury. Tannins contained in oak wood have strong antiseptic properties. The most beautiful and durable wood (stained oak) is obtained if it is kept in cold running water for one and a half to two years.

Of morenogo oak make expensive luxury furniture. Morainic wood has a deep dark color, almost black. It is almost an ideal material for furniture production, however, it is difficult to handle, as it is very dense and solid.

Birch wood is not very hard and dense, but viscous and homogeneous, has a not very pronounced texture.

Out of the shortcomings of this material, one should emphasize the tendency to crack and warpage, poor resistance to decay, pest damage. In addition, the wood of the birch dries hard. With all its shortcomings, this material is perfectly handled with a hand tool, a good plywood is obtained from the birch, the material is well polished and painted. Since birch wood is viscous and homogeneous, small relief embossing can be applied to its surface.

Aspen is a soft material with almost no knots, thanks to which it can be perfectly processed, but because of the porous structure small parts made from aspen can not be made.

Lime tree is widely used for making carved parts in the production of furniture. It does not crinkle at all and does not crack during drying.

Lime wood has a strong structure, well resists rotting.

Maple - a durable and dense material, almost not subject to buckling.

However, it decays rather quickly and is greatly damaged by pests. Maple is well processed, glued and painted. Maple wood is used for a variety of purposes, both in construction and furniture production.

Mahogany that grows in the rainforests is a very beautiful material of a rich red color.

It is used, mainly, for the production of elite expensive furniture. What is interesting is that "mahogany" is not a separate species, the name is used for many tree species with similar properties.

The mahogany wood is perfectly treatable, polished and absorbs lacquer. Because of the very high cost of mahogany, rarely make high-grade products, most often the material is used for the manufacture of individual parts.

Advantages and disadvantages of wood as a building material

The main advantages of wood:

• Low density, high strength.

• Low thermal conductivity.

• Simplicity and convenience in the processing of cutting tools.

• The wood is very well adhered and retains the fasteners.

• Ability to paint, polish, varnish the surface.

• Beautiful texture.

• Good sound insulation properties, the ability to absorb sound with shock and vibration.

• Excellent sound-emitting properties (resonance).

• High resistance to acids and alkalis, and therefore coniferous wood is used for the manufacture of various types of containers.

• Ability to bend. High bending ability is mainly of deciduous species.

• Good resistance to wear.

• The property of "warning" crackling about possible damage at critical loads.

Disadvantages of wood as a material

Anisotropy - the ability to change its mechanical characteristics depending on the place of growth, the breed, in the cross section of the trunk (core, core, sapwood). Change in the direction of the fibers, defects and deficiencies in their location, humidity and other factors. All of the above significantly complicates the choice of material for use in critical structures and products.

Uneven distribution of moisture in the trunk. Because of this, in certain places there is a stress, leading to cracking. Cracking, of course, refers to the shortcomings of wood, but in some cases it can be useful, since it can increase the density of joints of parts in some constructions (log houses, wooden pipes, etc.). If you fasten swelling wooden parts, then between them there is a pressure of 8 to 32 kg / cm2.

Low resistance to splitting

This disadvantage is also useful, for example, when harvesting firewood and other chopped assortments.

Propensity to decay of ignition, damage to insects and rodents.

Building materials made of wood

All species can be divided into several types:

• Round timber.

• Lumber.

• Semi-finished products, wood products.

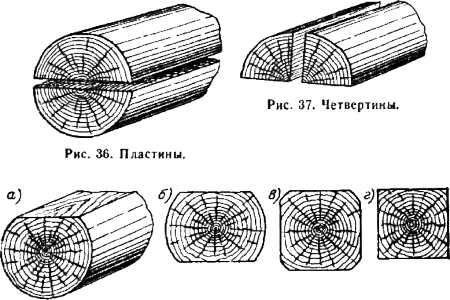

Round timber is trimming of a tree trunk, peeled from knots and bark.

All round building timber, depending on the diameter, is divided into logs, podtovarniki and poles.

The log has a diameter of the upper part of not less than 14 cm, its length is from three to five meters. Logs are used as a ready-made building material or go for sawing to obtain sawn timber.

For construction, logs of coniferous species are used most often, less often deciduous logs. For the production of plywood, alder, aspen or birch ridges are best suited (logs are cut off a trunk with a diameter of at least 20 cm). The variety of logs depends on its quality. The log is cleaned from knots and branches flush with the surface.

Podtovarnik - trim trunks of medium thickness, a diameter of about 8-13 centimeters, a length of 3 to 9 meters. They are used for a variety of purposes, for example, in agricultural construction for the construction of temporary and economic buildings, as well as in housing construction.

The pole is a thin roundwood, a little thicker than a branch, 3 to 7 centimeters in diameter, 3 to 9 meters long.

Round timber is stored in stacks according to length and grade. Untreated round timber is used less and less, due to the development of industrial production.

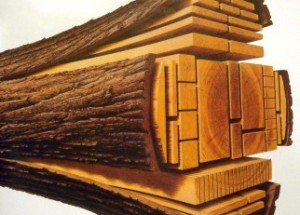

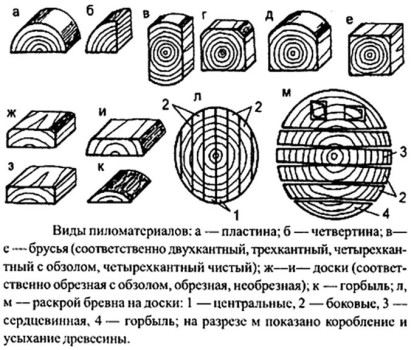

Lumber is the product of longitudinal sawing logs. Sawn timber without edges is called edging, with edges unedged. A timber with a partially removed edge is called a half-edged.

According to the method and form of longitudinal sawing, sawn timber is divided into:

• Bar.

• Board.

• Plates.

• Quarters.

• They mourned.

The bars have a thickness of more than 100 mm. Can be filed on four sides (four-edged) and with two (two-edged). The bars are made from both coniferous and hardwood. They are used in construction works as supports for interfloor overlappings, rafters, logs, etc.

The bar has a thickness of less than 100 mm, the shape is square or close to it. Length from 1 to 6 meters or more. The bars are used for the manufacture of joinery and various elements of wooden structures.

Board - a material whose width exceeds its double thickness.

Edged board - material in the form of a regular rectangle with four processed edges.

Unedged board - a material with untreated edges.

The thickness of the boards is from 13 to 100 mm, width - from 80 to 250 mm and more. The boards, sawn from coniferous wood, most often have a length of up to 6.5 meters, of hardwood about 5 meters.

Tes is a thin board (thinner than 32 mm).

All the boards and boards are divided into five varieties. In the construction works are used all without exception, in carpentry only the first and second.

Plate - the half of the log obtained by longitudinal sawing.

Quarter - the fourth part of the log, which is obtained when sawing along two perpendicular directions.

Slabs - the first spills, which are obtained in the process of sawing logs on boards and beams.

Marbled, quartered and plate are used in construction work as auxiliary and auxiliary materials.

All lumber is stored in stacks protected from snow and rain. Transportation of sawmills is most often done on railway platforms.

Finishing materials from wood

Finishing of wood has been and remains one of the most popular options for decorating the interiors of both private households and urban apartments.

Finishing of wood is very widely used both in interiors and in exteriors. Is used for:

• Facades.

• Ceilings.

• Sex.

• Stairs.

• Door and window openings.

Finishing materials made of wood are represented on the market by such types of products as:

• Boarding.

• Block house.

• Planken.

• Glued beams.

• Parquet.

• Decorative wallpaper.

• Wooden panel.

• Gusvarblok.

• Shield furniture.

• Floor board, etc.

Finishing materials are recommended to buy only from one lot, so that there are no noticeable differences in shade and texture. Before the direct work with wood begins, the material should be allowed to lie in the room, where the finishing will take place at least three or four days. This is necessary to ensure that the tree "acclimatized" - gave away or absorbed the right amount of moisture. For finishing works, the temperature in the room should not be in the range of 15 to 30 ° C, humidity not more than 30%.

https://www.youtube.com/watch?v=LDuYVn0Ev_Y