Since ancient times, mankind has used clay. Soft plastic material has found application at the device of furnaces-жаровен. Echoes of ancient symbolism, personifying the earth and the sun, are present in the form and material of the construction of the clay tandoor. The appearance on the private plot of a private house of this unusual oven is palpable at once - the dishes cooked warmly and tasty. How to build a tandoor with your own hands?

Content

Salam alleykam, tandoor or Hello, I'm your new stove

Trying once a delicious dish of oriental cuisine, it does not matter which: nuhat shurpa, Bukhara samsa or spicy Gijduvan shashlik, melting in your mouth, you will long remember the taste of food. A special taste for a meal prepared in tandoor.

For residents of Central Asia tandyr is a familiar word, especially as the clay oven serves as an important element and attribute of everyday life.

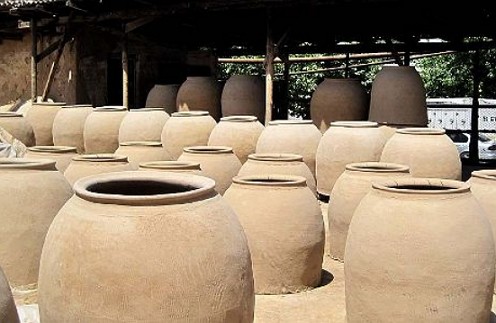

Furnace-brazier is a clay or ceramic hemisphere with a round opening at the top or side. The furnace volume can reach from 0.25 to 1 cubic meter.

The upper part of the furnace is narrowed, the diameter of the top can often be 0.7 m. An obligatory element of the tandoor is the top cover, which is opened with cooking products in the oven cavity.

Traditionally, the oven-brazier is installed in the yard of the house on a clay foundation or a furnace is buried in the ground. Certainly, such a stove-brazier will decorate any household plot. An indispensable condition will be strict adherence to fire safety rules when operating a tandoor and proper laying.

What are tandyr furnaces

Furnaces tandyr for cottages are both portable and stationary.

Portable furnaces in their shape resemble vases or amphoras having a two-level cover and wide metal handles. To strengthen the design, the furnace is tightened with metal strips.

The lid and neck of the portable tandoor amphora are equipped with a special device for lowering and vertical positioning of products for frying. In the lower part of the furnace there is an ash-pit for ignition and extraction of spent coal and ash. The originality of the portable design of the oven-frying pan was to many liking. But the desire to install tandyr is stationary for many people is a dream. Where can I get the tandyr drawings and how to build the furnace correctly?

The construction of a stationary tandyr

Structurally the oven-brazier consists of the following elements:

• grounds

• foundation

• a special tank

• outer layer of fireclay bricks

• Internal protective thermal filler

• grates, pits and awning.

To build a stove-brazier it will be necessary to erect a base for its installation, to make brick laying according to the order, to make thermal insulation (to smear the oven) and to decorate a convenient neck.

The design of the furnace, except for the ground version, can be arranged in the ground. The variant of the device of the furnace in the earth will be convenient in that case when the personal plot is limited in size and does not have sufficient area for erection.

To do this, excavate the pit and conduct an asbestos-cement pipe, through which air will be provided to the furnace.

templar

The inside of the oven-frypot has a peculiar barrel-like shape. Therefore, in order to give this form of construction it is necessary to build a template, using which can be attached and retained the necessary shape when laying a brick. Let us tell that between the inner vat and the outer brick layer it is necessary to leave a free space (10 cm) for the heat-insulating material.

Doing a tandoor with your own hands

The following materials will be required for construction of tandyr:

• sand-gravel mixture

• M400 cement

• refractory bricks

• mesh for masonry reinforcement

• refractory masonry mix

• steel wire Ø 3 mm

• Fireproof paint.

foundation

The peculiarity of the design of the furnace and its impressive weight suggest that the foundation must be done on a dense sand cushion 20-30 cm high. To build a frying pan it is necessary to make a solid foundation, up to 1 square meter. It is desirable that the base plate protrudes beyond the dimensions of the furnace by about 30 cm. For grouting the foundation, a cement slurry is used.

base (first row)

The base of the furnace is a layer of bricks laid flat on the finished foundation. Sutures between the bricks of the base layer are covered with clay. If the tandoor is dug in the ground, the edge of the asbestos-cement pipe for air supply must be located from the level of bricks of 5 cm. The pipe must be positioned at an angle of 45 degrees.

We prepare for the laying of bricks a rotary pattern (temalo). To exclude basting of bricks, the shape of the pattern is linked to the dimensions of the bricks used, taking into account the width of the seam from 3 to 9 mm. Spreading and fitting the width of the seams between the bricks of the first row, aligned by rotating the template by 180 degrees.

Then, each individual brick is removed, we put the masonry mortar on the surface and set it back in place. This method of laying bricks is called "on dry".

order

Starting from the second row of the furnace, we set the bricks no longer flat, but on the butt. The number of rows of the kiln can reach 4-6, and the inner diameter is up to 1.5 m. It is important to remember that in the bottom in the 1st row it is necessary to leave a gap for the ash-bluff.

The subsequent rows of the furnace are laid out according to the scheme: on a dry - check by a template - on a solution. Ideally designed pattern and width allow you to spread all the rows of the oven only with whole bricks.

Let's say that when calculating a template, one rule should be observed: the protrusion of the inner row is taken less than ¼ of the width of the brick or to produce a brick with a slight slope of the brick. This eliminates the need for internal lining of the furnace.

bricks reinforcement

After laying the rows of the furnace, it is necessary to make reinforcement of the brick layers from the outside using a thin wire. Bricks are wrapped in wire in three places: above, below and in the middle.

furnace coating

For coating the oven or thermal insulation, a special coating solution is required. Initially, the lubricating solution was made from clay mixed with fat with the addition of animal wool. You can do with a simple fire-resistant coating mixture, which you can prepare yourself.

The thickness of the coating layer should reach 10 mm. It is recommended to make a thorough, even layer from the bottom upwards. The upper part of the resulting furnace is shaped as a roller.

Then the tandoor is covered with a film for natural drying.

The final decoration of the exterior can be done whitewashing, as is customary in Asian countries.

After carrying out the work and drying, we make the roasting of the oven from the inside. Now the oven-brazier is ready to load the products for cooking.

More detailed information on the device of the furnace is presented in the video.