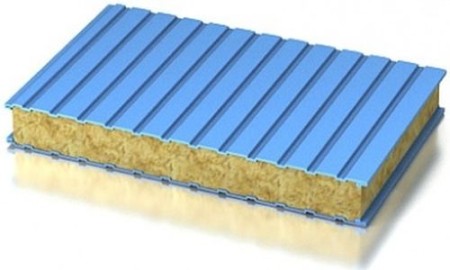

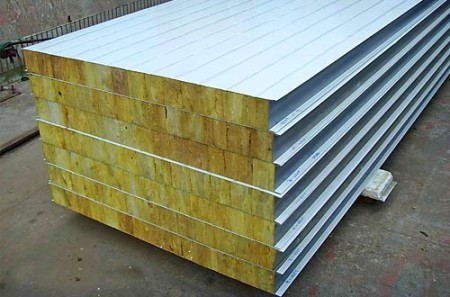

Sandwich panels, the reviews about which are the most positive - modern building materials, consisting of several layers - this is clear from the name itself. In the cut, the panel is very similar to a sandwich, which, in fact, is. Multilayer panels are widely used in the construction of residential and industrial buildings. They are durable, weigh a little, look attractive - all this gives sandwich panels a lot of advantages over similar building and finishing materials. Below we will talk about the materials that make sandwich panels, their varieties, applications, and much more.

Content

Advantages of sandwich panels in front of other building materials

Multilayer panels are among the builders are very popular not for nothing. This is a great analogue of heavy and labor-consuming bricks and concrete. With panels it is easy to work, they just load and deliver directly to the construction site. Since they weigh a little, the walls of sandwich panels do not press on the foundation, therefore, it can save and not build a massive monolithic structure. The wall sandwich panel is, in fact, an element of a full wall, with a heater and external trim.

All the elements of the walls are made according to the drawings right at the factory and the ready-made elements of the "designer" are delivered to the site, which can only be folded in the required order. Thus, a lot of time is saved and the building grows literally before our eyes. Specific figures: one plate with an area of 1 sq.m. weighs about 18 kg, and the thermal insulation properties of the plate thickness of only 18 cm are the same as those of a brick wall with a thickness of one and a half meters. Sandwich panels are not afraid of frost to -60 degrees and heat up to +50 degrees.

The building constructed of sandwich panels, if necessary, can be dismantled very quickly and reassembled in a new place, as a designer. Another important advantage of this building material is that its front surface is already finished with facing material and does not need additional ennobling.

The use of wall sandwich panels is broad: beautiful residential houses, administrative buildings, shopping and entertainment centers, etc. are being built.

So, the main advantages of the joint venture are the following:

• Speed of building construction.

• Ease of the finished building.

• Low cost of the building (up to three times cheaper than brick).

• Non-combustibility.

• Environmentally friendly.

• Strength, durability.

• Good heat and sound insulation.

• You can work with sandwich panels at any time of the year.

Types of wall sandwich panels

All wall sandwich panels differ, first of all, with the cladding material and the insulation used. For example, a material made on the basis of expanded polystyrene or polyurethane foam has good heat and sound insulation, is resistant to mechanical damage, is environmentally friendly and has a long service life.

Such panels are very light, which makes them very easy to mount. Work with them can be even in the most severe frosts - it does not affect the performance characteristics of the finished building.

Panels, in which the material of the central layer serves as fiberglass, are resistant to vibration, do not burn, do not respond to chemicals, have a low weight.

They absorbed all the positive properties of sandwich panels, but they have some disadvantages:

• Low resistance to sudden temperature changes.

• Fiberglass is prone to deformation and shrinkage.

There are also sandwich panels with a combined insulation - they are made using mineral wool and polystyrene foam. Such panels are fire resistant, durable and hardly miss a sound. Gypsum board, metal, paper, wood and polyvinyl chloride are used for the paneling.

Another interesting variant of sandwich panels is the construction of a phased construction. From conventional panels differ in that they are assembled right on the construction site, where they are subsequently mounted.

The main components of such panels:

• The self-supporting cassette profile.

• Internal insulation.

• Metal lining made of corrugated board.

Such panels are inexpensive, but mounting them is somewhat more difficult.

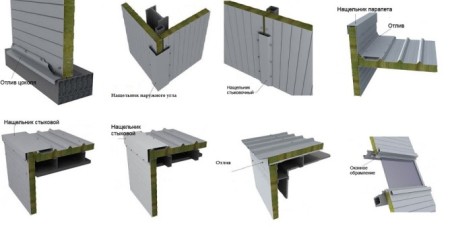

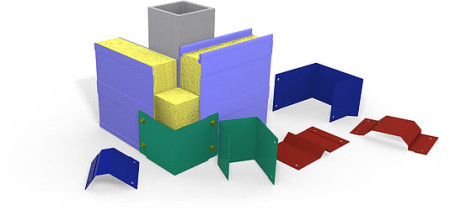

Sandwich panel assemblies

The sandwich panel assembly is a special coupling element, by means of which the panel is fixed to the support. From the nodes it depends on how reliable and reliable the finished structure will turn out. It should be noted that the fastening points are strictly individual for each object.

Their configuration depends on the following factors:

• The thickness of the frame, which will be attached to the sandwich panel.

• Which layout will be used - horizontal or vertical.

• Axial dimensions.

• Features of the climate in the region in which construction work is carried out.

Options for fixing sandwich panels are very many, but they are usually repelled from generally accepted, proven practices.

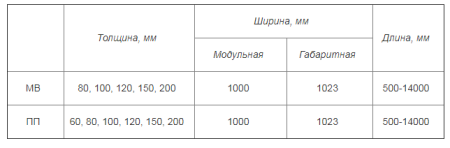

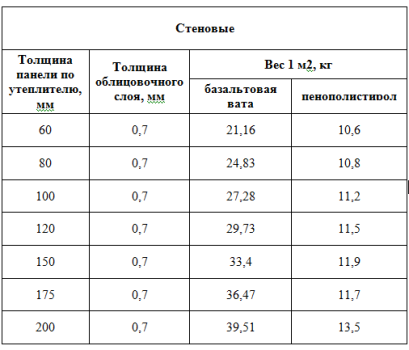

Sandwich panels: dimensions and weight

Wall sandwich panels are produced in several versions: a width of 1000 and 1200 mm.

Roof sandwich panels are produced with a width of 1000 mm.

The length of wall and roof sandwich panels can be from 500 mm to 14 000 mm. depending on the required specification.

With regard to the weight of the panels, it directly depends on the thickness of the panel itself and the type of insulation. This should be taken into account before starting the installation work. So, a sandwich panel with a filler made of mineral wool will be heavier than a panel with expanded polystyrene at the same thickness.

Fillers for sandwich panels

It should be noted that the filler of sandwich panels is fully "responsible" for the heat and sound insulation of the material. Today, the most demanded panels are filled with filler made of such materials:

mineral wool

It is not cheap and weighs a lot. Working with a mineral wool requires certain precautions, the material itself should be stored at a certain humidity, as cotton wool absorbs water very well. Wet cotton at negative temperatures swells a lot and a sandwich panel with such a heater inside is deformed. This leads to delamination of the outer layer and leakage.

For all its shortcomings, this material can prove to be indispensable if it is necessary to use non-combustible sandwich panels for safety requirements. For this reason, such products are used in the construction of industrial buildings, in order to avoid problems from the fire supervision services.

polyurethane foam

Sandwich panels with a filler made of this material are considered to be among the best in terms of thermal insulation, but they are expensive, they are not environmentally friendly, and, besides, they are flammable. Nevertheless, panels made of polyurethane foam are very much in demand in the production of low-temperature refrigerating chambers.

expanded polystyrene

The most optimal material, which successfully combines good insulation characteristics, low weight and moderate cost. Sandwich panels with polystyrene foam are used in the construction of almost any structure. If you need to quickly and relatively inexpensively build a building that will not be subjected to increased fire resistance requirements, sandwich panels made of expanded polystyrene are an excellent solution. This building material is ideal for small businesses - it can be a car wash, shop, storage room, etc.

Material of sandwich panels production

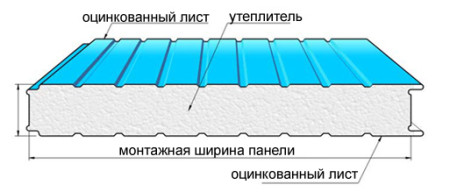

The material of the outer part of the panel depends on its strength and durability. It should be durable, lightweight, attractive in appearance and easy to install. In the production of sandwich panels as a finishing material use:

The zinced steel.

Zinc protects the metal well from the damaging effects of external factors and corrosion. To give the product an attractive appearance, metal sandwich panels are treated with polymers - plastisol, pural, etc., and also painted in popular colors according to the RAL catalog.

On metal sandwich panels, the price "starts" from 1000 rubles (the highest grade, mineral wool filler).

OSB stove. Such structures are called SIP panels. They are used in low-rise construction. Houses built from CIP panels are known as "Canadian".

PVC

Use in the production of extruded plastic allows you to get beautiful products that are used for internal facing works. So, for finishing window apertures, especially slopes, plastic sandwich panels are the most effective solution. They well insulate the window opening, do not freeze and do not allow condensation to form. On plastic sandwich panels the price is approximately the following: a plate with the size 10x1500x3000 costs from 1000 to 1200 rubles for a joke (expanded polystyrene)

Laminate

This type of wall sandwich panels is mainly used for facing door and window openings. To ensure that the finishing materials are in harmony with the main interior of the room, laminated sandwich panels can be used, which have a standard three-layered structure with plastic trim, which is covered with a special decorative film.

Fastening sandwich panels and installation features

Immediately before the installation of wall sandwich panels, it is necessary to check the steel frame of the structure and the basement of the building.

Preparatory work consists of the following stages:

• Checking the presence of the required amount of wall sandwich panels, all the necessary tools and materials for work on the territory of the construction site.

• After the basement of the building is constructed and waterproofing is applied to it, it is necessary to calculate the exact order of fixing the wall sandwich panels.

• Install the wall panels always start from the bottom, gradually moving up.

• To reduce the vibration of wall panels with columns, a special adhesive tape is used.

• Before starting the installation work, you need to mount special shaped or supporting components.

• Wall panels can be installed on wooden, concrete and metal facades.

• Sandwich panels, which are used for finishing or erecting the plinth, must have high thermal insulation characteristics.

• It is necessary to monitor the correct positioning of the outside of the wall panel - the rainwater should flow freely over it. Dimensions of sandwich panels depend on the features of the building under construction.

• The supporting sandwich panels are quite wide - the minimum width is 600 mm. If the buyer wishes, the inner and outer sides are treated with a special film protecting the panel from damage during transportation and during installation.

• The outer film is peeled off at the last stage of the installation of each panel, and the film on the inside of the panels is removed only after mounting all the panels, but no later than three months from the date of manufacture of the sandwich panel.

For cutting panels use tools that will not heat the material of the structure. It can be electric scissors, electric jigsaw, etc. The chips are removed with a stiff brush.

several rules for the correct cutting of sandwich panels:

• All work is carried out only in a horizontal plane. It is forbidden to cut panels vertically, in the air.

• The gap between the wall sandwich panel and the window or door opening should be 1-3 millimeters.

• Labels are placed on the two sides of the panel, between which a cut line is drawn. The straightness of the line must be controlled with the help of a building level.

• First cut one, then the second side, then cut completely and remove the cut piece.

• The front axle of the façade is the starting point for mounting the sandwich panel. Those parts of the design that are joined with windows, doors or other openings, it is necessary to accurately measure and cut off on the previously made markings.

When building a building from wall panels, you can install doors from both plastic and wood. The best thermal insulation properties have plastic doors.

The partitions are installed in the same way as a sandwich panel is attached to the wall. When fixing sandwich panels that are installed on load-bearing walls, care must be taken to ensure that the load is properly distributed.

It is necessary to control the force when tightening the fasteners. Work should be not in full force and you need to tighten the fastenings as follows. If you screw the screws too tightly, this will greatly reduce the life of the panels. A weakly tightened fastener will destroy the panel, since the load will not be distributed correctly.

To accurately calculate the required number of screws that will be needed to fix the panels, you need to consider:

• Possible load from the wind, which depends, first of all, on the height and location of the structure.

• Type of standing object: closed or open.

• The area of the facade where the panel is located. So, the wall panels, which are at the edges, must be fastened with additional screws.

• Number of fasteners and their load-carrying capacity.

It is very difficult to independently calculate the necessary number of screws, so it is recommended that you contact the designers who will provide ready calculations, respectively, with local climatic conditions.

When installing the panels, you should closely monitor the longitudinal joints. The appearance of gaps in these areas is unacceptable, since they have a very negative effect on the performance of the building. If there are gaps between the panels, cold bridges and condensation will appear.

If the climate in the region where the building is built is soft, then there is no need to further compact the panels. In severe climatic conditions, both sides of the longitudinal joint are treated with a special sealant. In addition, the use of a special sealing tape allows you to prevent air circulation and seal the fasteners.

Before installing the shaped elements, all the slots are carefully filled with a heater and assembly foam. Shaped elements are attached with an overlap of approximately 5 cm.

The fixing step is 50 cm. There should not be any gaps between the shaped elements and the sandwich panel, otherwise water will fall on the surface of the panel, which will worsen its performance characteristics and, consequently, the service life.