Many know that for the hydrophobization of wood and wood products use protective agents that reduce water absorption. Impregnation for wood during application does not change the appearance of the product. The whole secret of the working capacity of the protective material is hidden from prying eyes deep in the fibers.

Content

For an inexperienced master, materials - impregnation, priming or oil for wood are synonyms. The same available method of application and almost identical chemical composition are misleading: what is the more preferable to choose. Useful tips will help you figure it out.

What is necessary for the impregnation of moisture antiseptic

It is known that the building material wood, from which most of the elements of the interior and exterior decoration of houses are made, is exposed to moisture. Excess moisture in the pores of the tree causes the process of decay. For protection of wood The industry produces special antiseptic impregnations, which counteract the formation of condensate and the process of decay.

Impregnation for wood is a composition that does not create, in contrast to primers and varnishes, a film on the surface of wood. Impregnations have a liquid consistency of maximum absorbency.

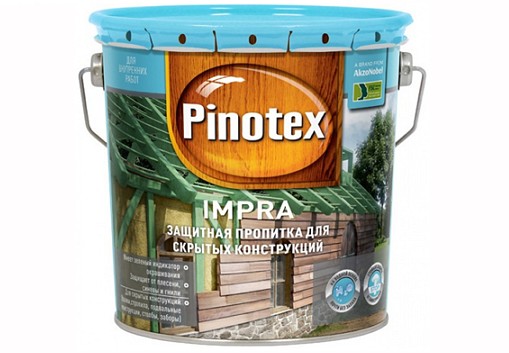

Deep penetrating impregnation of wood is subject to: wooden facades, garden furniture, truss systems, floor slabs, baths and saunas, window frames and temporary product protection.

Any impregnation of an antiseptic is simultaneously a priming layer for sawn and planed wooden structures. Among the variety of materials - impregnation, oils and wax, primers and stains, you should choose the right impregnation, which is different in chemical composition and purpose, and even more so in the correct processing of sawn timber and wood products.

Types of impregnations and primers

The main task of impregnation from decay and moisture is to protect wood and improve the characteristics and performance of the product.

Applying primer for wood provides a layer that enhances adhesion to the surface to be painted.

Therefore, you just need to know how to handle the lumber before applying.

selection criteria for impregnation

Distinguish impregnation for wood for outdoor work and internal use. The criterion for the choice of impregnations and primers is the penetration depth, the chemical composition of the substrate, the type of binder, the material consumption and the method of application or treatment.

depth of penetration

It is necessary to distinguish between impregnations according to the depth of penetration into the layer of wood: capillary, diffuse and hydrostatic, and also by the type of film formation.

Capillary impregnation penetrates into the depth of the wood under the influence of its own pressure.

Diffuse impregnation is well absorbed into the fibers through movement through capillaries and fibers.

Hydrostatic type impregnates wood fibers due to artificially created pressure by capillaries.

Any type of impregnation stabilizes the size of wood fibers, reducing the ability to crack and rot. We will suggest that impregnations without film formation are intended to protect sawn timber and products from mold and bugs. Foam-protective impregnations are able to protect wood from moisture, violating the decay of wood.

chemical composition and type of binder

The chemical composition of impregnations for wood, with a certain drying time, is as follows:

- water-based, t dry for 2-3 hours.

- on an organic solvent, t dry for 12-24 hours.

- based on the composition of nitrocellulose, t drying more than 24 hours.

Naturally, the chemical composition provides the performance characteristics of the impregnation material.

Helpful Tips

More information on the composition of the impregnation is shown in the video.

Nomenclature of wood impregnations and primers

There are impregnations and primers, which are water-soluble and waterproof materials applied before painting or used as a separate composition without preliminary priming. Such impregnations are suitable for application to sawn and planed wooden surfaces.

For example, water-dispersed alkyd impregnation Flügger Wood Tex TransparentFlügger Wood Tex Transparent, part of the Wood Tex processing, is used as an external facade treatment of wood. The flow rate of the solution is from 4 l / m2 to 10 l / m2, depending on the condition of the surface of the lumber.

priming antiseptics

Primers with a solvent base and adhesion bridge properties.

This type of primer is designed for the processing of wooden structures with sawn and planed wood with further application of frosting antiseptics or coloring.

For example, priming antiseptic formulation of oil-based impregnation TIKKURILA Valtti-Pohjuste is intended for external processing of wood with subsequent glazing and painting.

Useful tips on how to apply a protective coating on the skin are shown in the video.

oil treatment of wood

The treatment of wood with oil is suitable for solid finishing varieties of wood and is justified by water repellent properties. The technology of processing and applying the oil composition is no different from the application of ordinary impregnation and involves preliminary surface treatment.

Surface treatment of lumber before application

There are basic rules for applying impregnation and priming on wood.

We will show that these are the following stages:

- surface preparation (removal of foreign particles of earth, dust, dirt and paint)

- stripping and machining of the base layer

- uniform application of the initial impregnation layer

- application of subsequent layers after the final drying of the starting layer

- finishing and polishing.

Let's say that the price of impregnation is not a reasonable indicator of quality, because impregnations and primers have the same physical properties throughout the entire technological cycle of application.

methods of impregnation

Impregnations for wood with increased fluidity and density of the solution are applied by one of the following methods: application by brush, roller, spraying or dipping.

Judging by the reviews of the use of impregnation for wood, dipping or dipping the product into a working solution is effective for industrial processing of wood and a significant amount of lumber. In this case, the consumption of the working solution for processing is from 250 to 350 g / m2. Impregnation of wood according to the temperature regime is recommended in accordance with the manufacturer's recommendations.