The mastery of the popular and expensive specialty of a polypropylene pipe welder by the method of polyfusion welding has now become possible thanks to welding machines. It's up to the properly selected equipment and mounting tool. Likbez of welding illiteracy we begin with the basics of the properties and characteristics of PP pipes.

Content

Types of polypropylene pipes - properties and characteristics

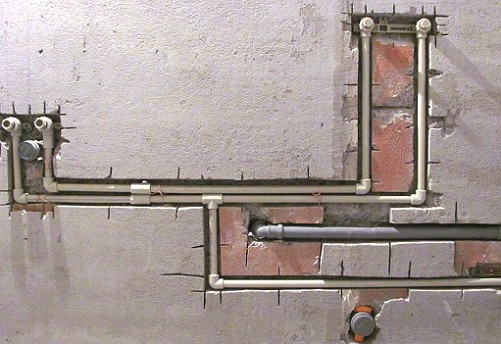

In modern water supply and water consumption systems, developers increasingly prefer polypropylene pipes, with the use of which it is possible to install trunk networks.

The features of the propylene material (random polypropylene copolymer) in the production of polypropylene pipes for water supply are high wear resistance to aggressive water and the ability to withstand the temperature for a long time. We will suggest that for the industrial production of pipes a random copolymer of polypropylene (PP Random copolymer) is used.

When choosing water pipes, it is necessary to take into account the performance characteristics of polypropylene pipes and types.

On what grounds do PP pipes for water supply classify and how to determine the best polypropylene pipes?

classification of PP pipes

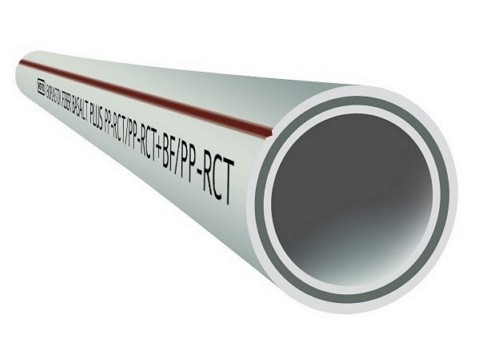

There are pipes for production - one-piece plastic (Fiber Basalt) and multi-layer reinforced (Stabi Plus), and also by the main criteria: designation, working pressure, carrier temperature, ø cross-section and dimensions of polypropylene pipes.

PN10 are designed for the installation of HV systems with a working pressure in the pipeline 1.0 MPa, a temperature regime of 20 ° C, an external diameter of 10-20 mm.

PN16 homogeneous pipes are designed for the distribution of cold and hot water supply systems with a pressure of up to 16MPa, a temperature of 60 ° C, a cross section of 16 mm.

PN20 are thick-walled pipes for cold and hot central water supply and heating, capable of withstanding the temperature of 60-90 ° C.

For example, pipes PN16 from the manufacturer Wavin Ekoplastik, an outer diameter of 110 mm with a wall thickness of 15.1 mm, a length of 4 m in length, with a working pressure of 16 MPa are the ideal solution for the installation of external and internal HW systems and the supply of warm water.

It should be remembered that the propensity of PP pipes to the thermal elongation of polypropylene pipes for hot water determines the necessity of using P and Z-shaped expansion joints for installation.

The video will tell about the types and benefits of polypropylene pipes.

But, of special interest are polypropylene PP-RCT three-ply polypropylene pipes with an oxygen barrier with aluminum reinforcement, which shortens the linear expansion at heating and PP-R 100 pipes, reinforced with glass fiber with the technology of pipeline installation by polyfusion welding.

Mounting tools and apparatus for welding polypropylene pipes

assembly tools

Installation of individual sections of the water supply system can not be performed without properly selected tools and apparatus. Moreover, frankly, it should be professional equipment, indicated by criteria, which polypropylene pipes can be welded.

The assortment of mounting tools and apparatus is represented by such devices:

• edged scissors

• by hand soldering irons and welding machines

• Special nozzles for the soldering iron and drills for the welded saddle.

With the use of trimming shears, the edges of the pipes are ideal for welding. The nozzles in the complete set of the welding equipment allow quickly to pick up conformity of the used model. The basic set of nozzles is the most commonly used pipes ø 20, 25, 32 and 40 mm.

Fittings or welded saddles are able to ensure the correct shape of the mounting holes.

But the lion's share of the mechanization of the welded process is accounted for by welding equipment, a soldering iron for polypropylene pipes, the prices of which allow you to purchase a device for carrying out work with your own hands.

welding equipment

Equipment for welding PP pipes is divided into the following types:

• Hand soldering iron for welding small diameter pipes (10-50 mm)

• machines for welding mechanical for welding pipes with a diameter of 400 mm and above.

Recall that distinguish three versions of the equipment.

option

A simple version of the configuration involves the presence of a welding and mounting wrench under the nozzle. This option is perfect for the master, who produces occasional welding of PP pipes of two diameters.

A medium-sized version is suitable for frequent welding using nozzles of different diameters.

Convenient transportation of the device to the workplace provides a roomy case.

The variant of professional equipment with a variety of nozzles and trimming devices ensures the convenience of daily use of equipment. By the way, the finished bundle of Professional will be cheaper in comparison with the purchase of individual elements.

Principle of operation and composition of welding machines for PP pipes

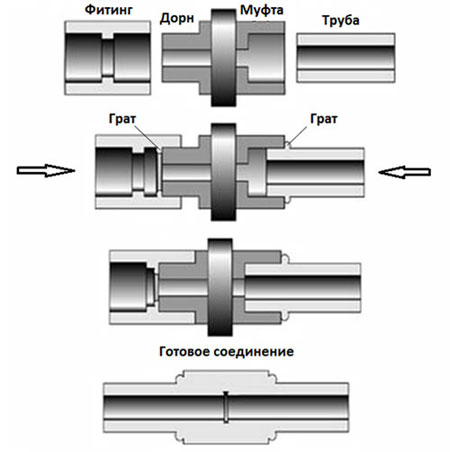

The principle of operation of welding machines is based on the ability of polypropylene to change the shape (diffusion) with short-term heating. After heating, the ends of the PP pipes can be joined manually, keeping the assembly immovable.

At the end of the process, the welded seam acquires the properties of the starting material of polypropylene.

For soldering reinforced aluminum foil and glass pipes, the technology is slightly different. Beforehand, it is necessary to remove the foil to the end face of the plastic, protochiv and removing the groove in the end, and to produce heat.

manual welding machine

The manual welding device for polypropylene pipes has been exaggerated, intended for heating the ends, consists of a heating plate and a thermostat. The difference between models of manual control devices is the power of the heating element and the shape of the metal plate for the nozzles.

The coupling shape of the nozzles allows heating the ends of the PP pipe from the outside and from the inside.

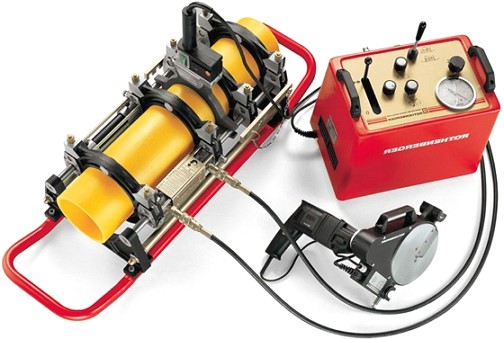

The power of welding machines can range from hundreds of watts to kilowatts. Thus, apparatus for small diameter pipes, have manual execution and low power.

The manual device does not contain a mechanical drive, the appliance is powered from a household outlet and such devices are successfully used for the distribution of water pipes in rooms. The most common variant of the heating plate is a tapering metal plate with heating nozzles. The type of heater can be flat and cylindrical.

mechanical welded devices

More difficult to consider mechanical welded devices for PP pipes of large diameter. The device is equipped with a frame and grips, by means of which the tube moves along the frame along the axis.

Mechanical welding machine for pipes of diameter greater than 400 mm expensive and designed for professional work.

Detailed information about welding machines is in the video.