If the plaster windows of the window can be called classics, then plastic slopes are the most economical finish. But there are still some ways to install slopes. How to choose the right material for finishing the slopes of the window, because this will affect the heat savings in the apartment?

Content

Window slopes in the interior

A significant element of the design of any apartment space is a window. From a qualitatively installed PVC window depends on the comfortable stay and reliability of the window structure.

Performing the assigned functions for heat and sound insulation, the PVC window must be equipped with window slopes. A good and properly installed window and slopes occupy not the last place in the interior of the room. Installation of window slopes can be done by yourself. The technology of installation of slopes is somewhat different and depends on the material of manufacture. For installation it is necessary to determine the type of construction and finishing of window slopes.

Types of window slopes

On the location, it is necessary to distinguish between internal and external slopes. The materials and technology for installing window slopes for exterior and interior structures are identical. Methods of finishing window slopes are:

• plastering

• slopes of plasterboard

• plastic slopes

• Slopes are wooden.

By what criteria is it necessary to choose the type of window slopes for later installation by one's own hands? The main criteria for choosing the type of window slope can be called:

• durability

• Easy installation

• subsequent care and maintenance.

Let's really appreciate the quality level of window slopes and the ways of finishing it.

Plastering window slopes is considered the most common and in-demand method of decoration. This method of finishing is suitable for internal and external slopes in houses of various types. However, a simple and relatively cheap option of finishing - plaster, does not fully meet the requirements of thermal insulation. The presence in the plaster layer of the slope layers with different coefficient of volume expansion and compression leads to the formation of cracks on the surface of the window slope.

How to make the plastering of the slopes of the window with your own hands, is shown in the video.

Competently and professionally installed window slopes from plasterboard, insulated with mineral wool or a thin layer of foam, will provide a good degree of excellent thermal insulation properties. However, there are a number of limitations to installing slopes from plasterboard, namely: drywall is designed exclusively for internal works, requiring additional finishing. To prolong the service life of gypsum plasterboard slopes, priming and subsequent finishing painting will be possible.

Window plastic slopes can be safely called avant-garde, possessing not only an attractive and expressive appearance, but also powerful potential opportunities. Plastic slopes can be installed both from the outside and from the inside of the room.

And the angle of the panels to the window plane is not strictly fixed. Installation and installation of window slopes of this type is carried out dynamically in just a few hours, excluding the appearance of an abundance of construction debris. Slopes of plastic and panels for window slopes perfectly match the type and texture of the material that the window structure.

This ensures a harmonious finished look. Among the estimated qualities of slopes from plastic and panels, the following characteristics can be named:

• resistance to hard UV radiation, according to ISO105 B 02

• resistance to fading, mechanical scratches and synthetic detergents, according to ISO 1518 and DIN 53778

• Insignificant coefficient of heat conductivity

• environmentally friendly material, developed according to the recipe of PVC indoor mixtures

• seamless assembly, ensuring the absence of fungi or miasms.

Wooden window slopes are an invariable attribute of an aperture made of natural wood, therefore are excellently used for finishing country houses. Simplicity of installation of slopes from a tree by connection "groove-in-a-groove" allows to make out window openings quickly and qualitatively. The connection and fixing of wooden slopes is carried out using self-tapping screws, preventing undesirable appearance of cracks and gaps.

How to install window slopes with your own hands

Installation of window slopes on the example of plastic panels

Before the installation of window slopes, the measurements must be taken. The purpose of the measurement is to determine the height, width and depth of the opening. This information will serve for the estimated cost of work and the acquisition of the necessary finishing material. After acquiring the necessary material, it is necessary to prepare the working surface of the slope for subsequent installation.

To install plastic slopes you will need:

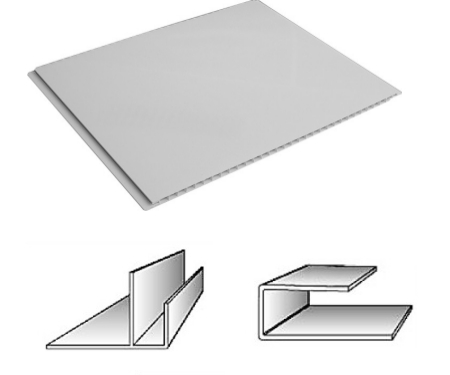

• Starting profile U-shaped

• F-shaped profile

• 15 cm wooden strip.

• insulation

• Self-tapping screws - 95 mm

• self-tapping "bugs" - 4,5 mm

• Sealant silicone is white.

The installation of plastic slopes is carried out in several stages. Initially, a wooden rack is attached to the perimeter of the slopes. Fastening is carried out by self-cutters in length of 95 mm. For an even slope arrangement, it is necessary to check for verticality and horizontality using the level. The wooden strip will serve as the working base for the subsequent installation of the panels. Then the starting profile is attached along the edge. Profile fixing is done using self-tapping "bugs".

It is necessary to set the start profile fairly tightly to the window. Then attach the F-shaped profile to the wooden rail. Grooves or grooves in the foam should be the depth and width of the panel sheet from 6-8 mm.

The next stage will be the insulation of perimeter slopes. As a heater for slopes, you can use a thin foam or mineral wool. The insulation can simply be glued to the wall, reinforcing it in some places. Now we mount the prepared plastic sheets.

Inserts sheets of plastic between the grooves formed as a result of mounting the U-shaped and F-shaped profiles. Mounting sheets of panels starts at the top of the slope. Places of abutting plastic panels to the window and corner joints after installation of slopes are recommended to decorate with white silicone sealant.

For more information on the process of installing window slopes, see the following video.