In most people, the word "chimney" causes associations with the usual brick or asbestos pipe, towering above the ridge of the house. Certainly, pipes made of brick and asbestos are used to this day, but still in houses built today, they are increasingly replaced by more advanced chimneys of a modular type.

What is a modular chimney?

So what is this type of chimney, and what benefits does the developer get from installing it? As is clear from the title, the design of the chimney is a few details-modules, which are very simple to connect with each other, like the elements of the designer. The main advantage of modular chimneys - using parts of different sizes and shapes, it is possible to assemble a chimney structure of the necessary configuration - for example, enveloping possible obstacles: beams, balconies, peaks, and other construction and architectural elements.

Simple installation of a modular chimney can be done on its own, provided that the instructions given by the manufacturer are strictly observed. In this respect, modular structures favorably differ from brick chimneys, which not every bricklayer can build. As is known, for many centuries the construction of chimneys was handled by bricklayers of a narrow profile - the so-called "stoves", today any homeowner can perform this work.

Modular chimneys are distinguished by high efficiency and low weight - that is, the foundation for such a chimney is not necessary to build. Sometimes a modular chimney can be mounted inside an already operated brick chimney. Thus, the efficiency of the chimney structure can be increased severalfold. Another undeniable advantage of modular structures is the ability to quickly replace damaged chimney parts. Modular chimneys are metal, but they are not afraid of corrosion, as they are made of galvanized iron or stainless steel.

Among other things, some elements of modular chimneys are protected by a layer of thermal insulation.

Online http://www.vvd.su/dymokhodnye-sistemy1/keramicheskie-dymokhody you can purchase and obtain all information about modular chimneys.

Modular chimney unit

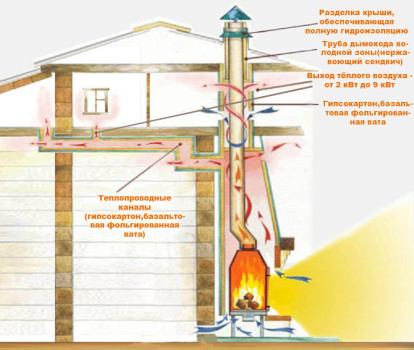

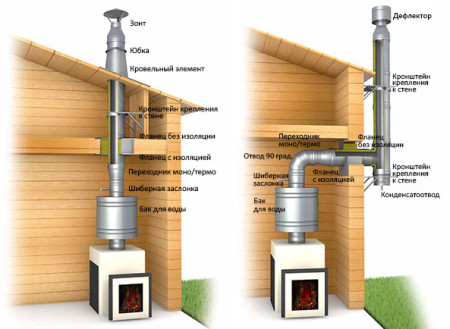

It would be a mistake to imagine a modular chimney simply as a straight vertical pipe leading from the boiler to the outside. In most cases, there are areas with a slope, or even horizontal ones. The main part of the modular chimney consists of pipes that are connected by means of tees or adapters.

If a tee is used for the connection, in this case the connection is equipped with a removable glass, necessary for cleaning the pipe from soot. The mounting brackets are attached to the walls of the modular chimney. The interval of their location is about 1.5-2 meters.

If it is necessary to lay the chimney through any kind of cladding, a wall, a ceiling or a roof made of flammable materials, a pipe passage is used. Elements of the pipe pass have a larger diameter than the pipe itself, and do not allow its contact with combustible building materials.

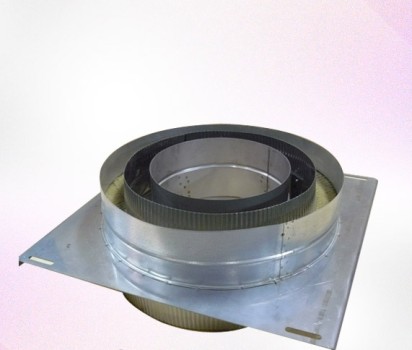

Roof cutting also applies to mounting elements. It is a small branch pipe fixed to a metal sheet. Its function is to ensure tightness at the exit of the chimney from the roof and to protect the space under the roof (attic, attic) from water and debris.

The chimney pipe itself passes inside the roofing. On top, the pipe is additionally equipped with a clamp-apron. In addition to all of the above, there are a number of additional mounting elements - any manufacturer who develops its own parts all depends on the technique and features of the installation.

Materials for manufacturing modular chimneys

Modular chimneys are made from different materials, each of which has its own weak and strong sides. Modular chimneys are made from:

• Metal.

• Plastic surgery.

• Ceramics.

• Glass.

• Volcanic rocks.

Choosing the material, you need to build on the operating conditions of the chimney, the complexity of the design, and, of course, its cost. The most common are steel chimneys. A steel chimney pipe may have one or two walls. A single-wall modular stainless steel chimney is best suited for a boiler room in which a heat source is installed.

For example, you can connect, for example, a fireplace to a ready-made operating chimney without any problems. Among the advantages of single-wall chimneys, it is necessary to note, first of all, their rapid heating, which eliminates the formation of condensate, as well as the rapid and complete removal of combustion products of fuel. This design is very durable and reliable, it does not accumulate soot. Modular single-walled chimney features a low heat capacity, a good level of thermal insulation.

A double-walled modular chimney is two pipes of different cross-section, inserted one into the other.

In the free interval between the pipes is installed heat insulation material, which makes the chimney work more efficient. Such structures can be mounted both inside the building and outside. If necessary, the chimney can be tilted if you need to bypass any obstacle.

A double-walled chimney, like a single-walled chimney, has a sufficiently high thrust, effectively removes all combustion products, very quickly heats up, is not susceptible to corrosion, perfectly resists the effects of atmospheric factors.

But, along with advantages, modular systems have several drawbacks. So, if the construction is large, the steel chimney will have a big weight. Consequently, a support structure is needed. In addition, not all developers want to see over their roof unpretentious steel pipes.

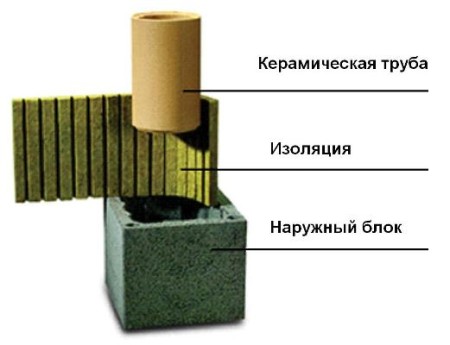

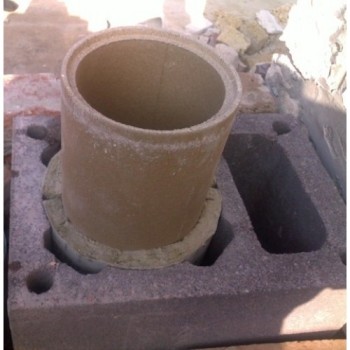

Ceramic construction has absorbed all the advantages of a brick chimney, the simplicity and speed of mounting modular structures.

On domestic ceramic designs are still not very common, but manufacturers are constantly expanding their range. The advantages of ceramics include absolute resistance to a damp and aggressive environment, as well as substances that are contained in combustion products, temperature changes (the temperature in the chimney cavity can exceed 600 ° C), as well as the heating rate, excellent traction, compact external dimensions. Disadvantages: heavy weight, the need for a foundation, the inability to bypass obstacles, since the ceramic construction must be installed only vertically.

As one of the options, you can consider a chimney made of ceramics and equipped with a steel or foam concrete casing. Inside the structure there is a heat-insulating material. This chimney combines the advantages of steel and ceramic structures, and its performance is very high. Of course, the price of such designs is appropriate.

Aluminum modular chimney, despite the name, is not completely so.

The main part of the construction is really made of heat-resistant high-quality aluminum, capable of withstanding the temperature of more than 250 ° C without problems, the rest of the parts are made of stainless or heat-resistant steel. Such a chimney has a small weight and is distinguished by a variety of forms of construction.

Plastic chimneys are used only when the temperature of the combustion products does not exceed 120 ° C. The plastic is not subject to moisture and aggressive environment, it is durable, but it does not have high strength, therefore it needs protection from mechanical damage.

Fireclay module is a pipe that has a thermal insulation coating and an external protective steel or foam concrete cover. This design has high performance characteristics and is quite expensive.

Glass chimneys - a rarity, they are very expensive and difficult to install. Their main advantages are thermal inertia and total immunity to external factors.

Quite often in the market there are chimneys from asbestos cement. It should immediately be noted that such pipes are strictly forbidden to use in residential buildings, since asbestos-cement has a very negative effect on human health, and can contribute to the development of malignant tumors.

Manufacturer of modular chimneys

The quality of the modular design is due not only to the material of manufacture, but to the good faith of the manufacturer. In order not to buy into a high-quality fake at first glance, you need to carefully study all the offers of the market, the price / quality ratio of the reproducers of interest, be sure to review the product reviews. At purchase it is necessary to demand the certificate of quality, the permission to realization, and operation of a product.

As for the manufacturers of modular chimneys, there are many, but so far not all work in the domestic market. For an approximate introduction, below is a small list of the most famous companies engaged in the production of modular structures:

• Selkirk.

• MK.

• Raab.

• Pougoulat.

Bofill, and many others. Among the Ukrainian manufacturers it is possible to note the firm "Sofia", which produces modular chimneys of high quality according to German technology. All listed companies produce only metal modules, but the products of each of them have their own flavor. Thus, Bofill manufactures flexible chimneys, which allow assembling the design of any configuration. Raab products are made from special mirror steel. Some models can be used for any type of heating, others are only operated under certain conditions (temperature, pressure, fuel, etc.). This must be taken into account when buying.

Requirements for modular chimneys

There are very few requirements, as such, but, nevertheless, they must be strictly observed, and then the system will function without fail in the entire period stated by the manufacturer. Below we will list the basic requirements for modular chimneys:

• If equipment that burns solid fuel is used, the smoke channel must ensure complete elimination of toxic gases - combustion products.

• Any heat source must have its own chimney. It is inadmissible to connect several heat sources to one chimney, for example: a stove, a fireplace, a boiler, etc.

• The chimney pipe must be of the same diameter along the entire length and not taper to the outlet.

• The elements of the steel module must be made of special steel, resistant to corrosion. The wall of the pipe must have a thickness of at least 1 mm.

• Docking of individual pipes in the interfloor is not permissible.

• The design of the modular chimney must be equipped with devices to clean it from soot.

• Between the chimney and flammable building materials, a cutting must be made to protect against fire.

• The height of the chimney directly depends on how it is positioned relative to the ridge, and on the type of the roof itself. For example, if the roof is flat, enough height of half a meter. For a pitched roof, the height of the chimney depends on the distance between the chimney itself and the ridge:

• 1.5 meters - the chimney rises above the ridge for at least half a meter.

• 1.5-3 meters - the chimney does not rise above the ridge, but it is not lower than it.

• More than 3 meters - the chimney is not below the line drawn from the ridge down at an angle of 10 °.

How to assemble a chimney

Unambiguous advice is difficult to give, since the method of installation is almost always determined by the manufacturer. Each firm has its own assembly technology, which is described in all details in the instruction sheet attached to the product. The installation of modular chimneys can be compared with the assembly of the designer - all pipes are assembled in size, and fasten each other with clamps every 1.5 to 2 meters. The sequence of installation is always the same - start from the bottom point, from the connection point, for example, to the boiler, and gradually the whole structure is built up.

If it is necessary to lead a chimney through a roof or a wall, leave a gap of 15 centimeters if the pipe is protected by a thermal insulation layer, or goes through a through pipe. For pipes that do not have thermal insulation protection, a gap of at least 35 centimeters is required. The gap is filled with a dense thermal insulation material that does not support combustion. Some modular chimneys, as in the photo below, can be mounted outside the building.

This greatly simplifies their installation. Chimneys made of stainless steel, placed outside, must be insulated to prevent condensation. To the wall they are fixed with special brackets, or placed inside the supporting structure.

In the insulation require pipes located on the street, but also those that are located in unheated rooms, for example, in the attic. it is strictly forbidden to enclose the pipe with a brick or cover with a layer of mortar - this will inevitably lead to the appearance of damage and cracks. At the bottom of the chimney must necessarily be a special hatch to clean the pipe of the residues of soot.

If we talk about the cross section of the chimneys, it can be either rectangular or oval. It's good if the pipe is square or round. For rectangular pipes, the aspect ratio should be 2: 3. If there is a choice, it is best to use a round tube, since vortices form in the corners of a square or rectangular pipe, as a result, soot accumulates and the draft is weakened

A modular chimney requires proper periodic maintenance - this directly determines the life of the chimney. It is recommended to clean the chimney no less than two or three times a year.