The topic of building baths is extremely popular on the web. There are a lot of drawings, plans, tips, videos, etc. But about such details as the door to the steam room, there is relatively little information. But this is not only part of the interior of the bath. The door to the steam room is not so simple as it seems at first glance, and it is being demanded, since the door is operated under very harsh conditions.

Below you will find information on how to properly choose and install the doors in the steam room, as well as a few tips for the self-made wooden doors in the steam room.

Content

Requirements for the door to the steam room

When building a sauna, the doors to the steam room need to be given special attention, since it is the door that helps to keep the heat in the room.

In order for the door to cope with its task, it must meet several important requirements:

• The door must be tightly closed so as not to miss the precious steam from the steam room,

however, do not make a completely sealed room from the steam room - fresh air still has to come in, and therefore, when installing the door, small gaps are left between the box and the sheet.

• The door to the therma should keep the geometry, do not deform in conditions of high temperature and humidity.

• The correct door to the steam room must be safe - open only to the outside, not to be too heavy, not to have parts that can cause a burn if touched - this applies to handles, latches, locks, etc.

Materials for the door to the steam room

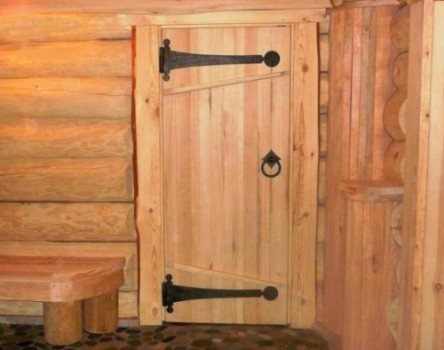

wood

The best option for doors in the steam room. You just need to choose the type of tree.

Some sauna owners negatively speak about conifers, referring to the large tar content, and this is difficult to argue with, as hot resin can cause severe burns. But if it is a Russian bath with a traditional steam room, then there are no such high temperatures in it that the wood tar begins to melt. The maximum temperature to which the steam room is traditionally heated is 85 ° C. Thus, for the doors in the steam room of the Russian bath house, spruce and pine are perfect. Steam room whose dimensions are relatively small, should always have a fresh air supply. Therefore, it is not necessary to make something out of a steam room like a sealed pressure chamber. If the material for the door is a thick board, it does not need to be trimmed any more - neither the canvas nor the perimeter. The right door to the steam room keeps the steam without any problems. To insulate a door it is necessary only when it is made of a thin board. In this case, the door to the steam room is often frayed with felt. Thermal insulation in this case is significantly improved, but with drying of the felt there are problems

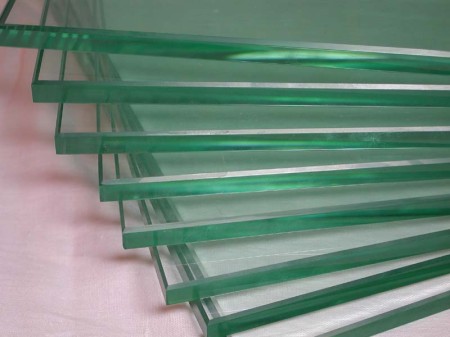

glass

The main requirements for glass doors in a thermae are practically the same as those for a wooden door - tightness and safety. This should be taken into account when choosing a door, and only buy doors made of heat-resistant and impact-resistant tempered glass.

The advantages of glass doors in front of wooden ones include the following:

- Exceptional resistance to extreme conditions in the steam room. The glass is not deformed, and simply "ignores" the high humidity and temperature in the therma, so glass doors can serve for a very, very long time.

- Convenience in operation. The doors to the glass therma are very simple and convenient to wash using the most common detergents. With proper care, the glass doors will not lose their original appearance throughout their life.

- The glass door to the steam room, in addition to its immediate task, can perform a few more: to decorate the interior, visually increase space, make the premises more light. Glass doors in the steam room are made of transparent or frosted glass, which, at the request of the buyer, is applied any pattern or pattern.

Such a door can become a highlight of any bath.

types of glass doors in the steam room

Today, the market offers an extremely wide choice of such products, and you can choose a door of any size, color, etc.

Also, to the colored door you can choose decorative accessories to your taste. In the assortment of most manufacturers you can find glass doors of tempered glass - transparent, matte, mirror in a wide range of colors: green, gray, "bronze". In addition, glass doors are made to order.

The glass door to the therma can be pendulum or swinging. The pendulum door opens in both directions.

Such doors are installed with fixtures in the ceiling and the floor.

Swing doors open only one way (for a steam room - outside), mounted in a door frame on the hinges.

Wooden door to the steam room with your own hands

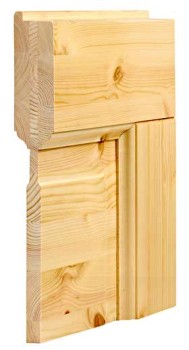

manufacture of a tying of a wooden door

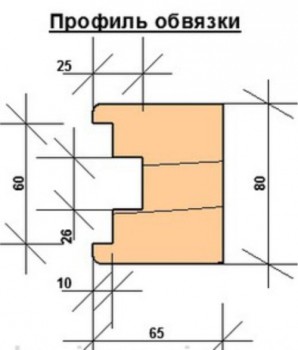

Strapping for a wooden door in a steam room is done in this order:

In the bars with the help of the router make grooves. First, the grooves are machined, leaving a tolerance of a few millimeters to each side for subsequent finishing milling. The grooves intended for the lining make a depth of 1 centimeter and a width of 6 centimeters, slots for the boards - 1 centimeter deep, and 2.5-2.6 centimeters wide.

Vertical profiles of the strapping are cut with a hacksaw to a length of 57 centimeters. At both ends of the profiles make a seat for connection with the vertical profile.

Vertical profiles are cut to a length of 180 centimeters.

After this, the frame is assembled, the final marking is done, the grooves are grooved. Then the frame is collected again, angles are checked, measurements are made for the joints with the door leaf in the steam room.

manufacture of door leaf

The door leaf is made in this order:

First of all, they prepare an extreme board - with the aid of a plane, they completely clean the spike to the body of the board. The canvas of plank boards is collected on a flat surface, beginning with the first board in the sequence "spike in the groove". The width of the canvas should be slightly larger than the width of the door, about the width of one board.

Next, the pencil is made at the right points to the desired width of the door, connect them with a line. It is necessary to leave a few millimeters of tolerance for finishing.

A circular saw is cut along the last board, after which the fabric is assembled. On the table, a flat bar is fixed as an abutment for the cloth. Further, resting the first board in the bar, collect the canvas, pre-processing the spikes and grooves with waterproof joinery adhesive. After assembling the canvas, one more stop bar is fixed to the table with a small gap. Stub bars should be of the same length as the blade. When fastening the laths, you need to leave a small gap, in which wooden wedges are driven - thus, the boards of the sheet are pressed tightly against each other, so that glue appears on the joints. Remains of glue need to be removed. In order that the canvas does not swell, a sheet of plywood or chipboard is placed on top of which something heavy is put on.

After the glue completely withers, check the quality of the fabric assembly. If there are gaps, they are closed with sawdust mixed with joinery glue. All unevenness from the canvas is eliminated by a plane and a wooden block wrapped in sandpaper.

On the canvas, using the tape measure, gon and ruler, precise contours of a door of length 1720 and a width of 570 millimeters are applied, starting from the ends adjacent to the support bar and the outer part of the first board of the web. After this, the saw blade is cut with a circular saw along the outlined contour, the cut places are sanded with sandpaper.

Further along the perimeter of the canvas, it is necessary to make a spiker with a throat width of 1.5 and a width of 2.6 millimeters. To do this, use stubborn straps, which are fixed on the table along the canvas. The bars are fixed in such a way that their upper parts are located strictly horizontally in one plane. The door to the steam room, the dimensions of which were calculated in advance, is placed strictly parallel to the upper faces of the stop bars, which will serve as a support for the router.

Further, the milling cutter is mounted on the studs and the spike is milled in several passes.

After the whole contour is processed, the cloth is turned over and the work is carried out in the same sequence, by controlling the caliper with the thickness of the stud. The thorn should be a little thicker, so that it can later be adjusted exactly when the linen is placed on the harness.

door lining

You can cover the door with a lining in the process of tying the canvas. But it will be more convenient to do the skin as follows:

Take the billet stocking a little longer than the line, passing at an angle of 45 degrees from one long side of the cloth to the other. The panel is fixed to the door leaf with screws into the groove. Next, the whole lining is installed, completely covering the sheet. Next, on the car, draw a contour in such a way that the ends of the lining do not interfere with the binding, on each plate the lining is put, then the lining is dismantled and cut along the outlined contour. After that, all the elements of the skin are fixed in place and attached to the canvas with screws or nails in the groove.

The extreme elements of the lining must be fixed in such a way that the beams of the strapping hid the heads of the screws.

final door assembly

All work on the complete assembly of the door into the steam room is reduced to fastening the strapping to the canvas.

Pre-prepared bar stitches inserted into the spike of the door leaf along the perimeter with a slight interference without gaps. If necessary, the spike and groove are additionally milled.

Finally, check the quality of the assembly and glue the joints with glue. It is often advised to use PVA glue for this purpose. It should be noted that this glue for carpentry is not intended, in addition, it is destroyed under the influence of moisture. It is recommended to use a quality waterproof adhesive, for example, the universal polymer adhesive Dragon. The strapping is additionally attached to the canvas using self-tapping screws.

Screws screwed into the harness with a step of 20-25 centimeters. The hat of the screws must be dumped into the wood a few millimeters so that they do not interfere with the installation of the door hinges. In addition, the beams of the strap must be additionally fastened to the corners. The lower bar of the strapping is usually not glued. This is done in order that, if necessary, you can disassemble the door for repair or replacement of individual elements.

Installing the wooden door in the steam room

One of the main points of installing a wooden door in a therma is the installation of the threshold. Its height should be no less than 15 centimeters, although sometimes it is quite permissible to height up to 30 centimeters. Between the lower part of the door and the threshold it is customary to leave a small gap - about 2 centimeters, in order to circulate fresh air in the room of the steam room.

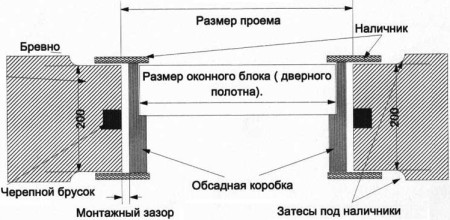

Installation of the doors in the steam room in the wooden baths is done using the window. For mounting in the casing, grooves are made, and on the logs in the doorway - ridges - the same groove and spike, with which the casing is attached in the doorway. The window (casing box) is necessary in order to avoid twisting and deformation of the door into the therma when shrinking the wooden building. The box for the doors in the steam room is made of thick beams.

In the opening it is installed in a comb way. In the doorway of a wooden bath, the ridges are carved and nests are made in the lower log, where the bars are inserted with pre-selected spikes. At the bottom of the doorway you can install a thick log, which will later serve as a threshold.

If the bath is stone or brick, then for the door opening to the steam room use massive bars or boards with a width of 10 and a thickness of about 5-6 centimeters. In the boards choose a quarter, the depth of which should match the thickness of the door.

The width of the quarter is on average 1.5-3 centimeters. The boards of the door frame are connected to a spike. The box is installed in the doorway in such a way that the door opens outward. Next, the box is set on a level strictly vertical and fixed to the wall.

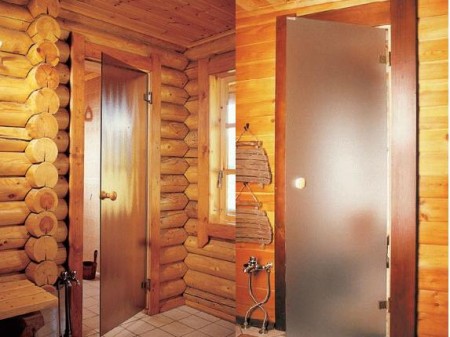

Installing the glass door in the steam room

To ensure that during the installation of the glass door in the steam room did not encounter difficulties, it is necessary to provide several important points in advance:

• Measurement accuracy. The glass door, unlike the wooden door, is no longer possible to fix. Therefore, you need to remove the dimensions as accurately as possible.

• Carefully prepared door installation site. The glass door should be installed in a pre-prepared place - in a door frame or in walls and floor. In addition, you need to immediately determine which side will open the door - to the right or left. In this case, do not forget that the door in any case should open out.

• Having an assistant for work. The glass door, designed for installation in the steam room, weighs a lot, and without additional assistance here can not do.

• Accuracy and accuracy in operation. Glass, even tempered, remains glass, and can break, so during the installation should be careful.

Requirements for the fittings of glass and wooden doors in the steam room are the same: all elements must be resistant to moisture, be comfortable and do not cause burns. As for the aesthetic component, it is very important for a glass door. Therefore, before installing, you need to pay attention to selecting all the elements. Hinges should be chosen from materials that have anti-corrosion properties, handles - only from wood.

Unpacking the glass door, you do not need to throw out the straps from the package - they will be useful in order to lay on them a canvas - it will be more convenient to lift it.

Lifting the door leaf, it is placed in the doorway, fixed with wooden wedges. Having checked all the necessary parameters necessary for normal operation of the door (clearances, geometry, etc.), the door is exposed and the screws in the upper part of the door frame on the hinge side are twisted slightly. Verifying the verticality, the same manipulations are carried out at the bottom of the door.

After installing the box, the glass door is inserted into the hinges and tightened. It is important not to overdo it so that the glass does not crack. The door is checked for symmetry, gaps, tightness to the box, after which it is possible to install handles and latches.

The glass door to the steam room is the most modern solution. The installation of the glass door can be done on its own, the main thing is to take into account all the nuances and follow the instructions given above. More about installing glass doors you can learn from the video:

https://www.youtube.com/watch?v=jBLnmsWpYNc