Polystyrene is a material of predominantly white color with a honeycomb structure. The material itself consists 98% of the air, which is in the foamed plastic masses. The microcells in which the air is contained are reliably isolated from each other, therefore the foam has excellent thermal insulation properties. This material is widely used for insulation of buildings, in the manufacture of refrigerators, as a protection against freezing of various communications, etc. Below we will take a closer look at the characteristics of foam and its use in construction.

Content

Polyfoam as a heater. Characteristics, advantages and disadvantages

As we have already said, polystyrene is a plastic mass, foamed with air. The foam plate weighs very little, because inside it is almost one hundred percent filled with air, which makes the foam plastic an excellent heat insulator. The material of which the foam is made has a slightly higher density than the raw material.

advantages of foam plastic as a heater

- Polyfoam is an environmentally friendly material. Does not pose any threat to human health, since it does not release toxic substances.

- Unlimited shelf life - the foam does not have fungi, mold, moisture and microorganisms.

- Low thermal conductivity, high thermal insulation properties.

- Styrofoam does not burn without a source of fire. It certainly can catch fire, but if the source of fire is removed, the foam will immediately go out.

- Very low weight - does not create additional stress on the building and foundation.

- It is very cheap, durable, with foam it is easy to work.

disadvantages of foam plastic

Like any building material, polystyrene is not without some disadvantages:

- Extremely unstable to mechanical damage, requires additional protection.

- Instantly destroyed when exposed to any solvents and nitro dyes.

- Practically does not let in air.

- Rodents very often damage sheets of polystyrene, arranging nests there.

Heat insulation of walls with foam plastic

Polystyrene is a perfect insulation for walls both outside and inside. But more often still do external insulation work with foam, as in this case it is possible to move the freezing point to the outer wall, thus preventing the cold from entering the building. Walls that go out into the street, insulated with polystyrene from the inside is not recommended. The thing is that the wall should be warmed from the inside, and a sheet of foam plastic will block the access of heat to the wall. As a result, the dew point is displaced either inside the wall, or it will be between the wall and the sheets of polystyrene foam. This is very bad, since in the vicinity of the dew point condensation begins to condense, which will freeze in severe frost and gradually destroy the wall. For this reason, the insulation of the walls with foam is the most preferable option. Sheets of foam plastic after installation must be finished with a layer of strong plaster, as the foam does not have high resistance to mechanical damage. When the facades are heat-insulated with foam plastic, plastic dowels must be used for fixing plastic plugs, since heavy finishing materials are often mounted on top of the plaster layer - tiles, siding, lining. Polyfoam can not withstand the load and break away from the wall.

Warming of the floor with foam plastic

Polyfoam is a good material for floor insulation. Fitted on the floor, polystyrene not only saves heat, but also significantly mutes the sounds of footsteps and moving furniture, which is especially important for multi-storey buildings. The thickness of the foam, which is used to insulate the floor, should be at least 5 centimeters. The sheets are laid over the waterproofing, after which the seams between the sheets are sealed, and only after that a rough screed of the floor is made.

Roof insulation

There are several ways to heat insulation foam roofs: ventilated, "cold" way, and unventilated, "warm". In the first case, sheets of foam are mounted from the back of the roof to prevent the formation of water vapor.

In the second method sheets of foam plastic with a thickness of 7 centimeters are laid on the entire surface of the roof, and poured from above with a layer of bitumen.

Foundation foam insulation

Warming the foundation, it is necessary to take care of reliable protection for sheets of polystyrene, since they will be subjected to significant loads. The earth will constantly pressurize the insulation, and in winter the load increases many times, due to the punching of the soil. As a protection for foam plates use either brickwork, or produce a monolithic pouring of concrete.

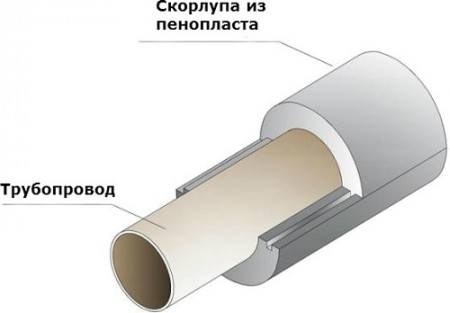

Warming of communications

Recently, polystyrene is very often used for the insulation of a wide range of utilities - sewers, water pipes, heating mains. In these cases the foam plastic is practically indispensable, because due to its heat and waterproofing properties it helps to avoid pipes freezing and serious troubles connected with it. In addition, polystyrene is used for thermal insulation of ventilation and telephone cables.

Ways of fixing foam on the walls

Since the foam is most often used for warming walls, it is necessary to consider this issue in detail. So, to attach a sheet of foam to the wall can be one of the following ways:

- With glue.

- With the use of dowels.

- With the help of glue and dowels - in case the heater will be lined with heavy material.

All these methods are widely used for insulation of various types of buildings. Glue is most often used for internal work, since reinforced fastening in this case is often not necessary. Glue for foam plastic can not be diluted with solvents, as they very quickly destroy the foam.

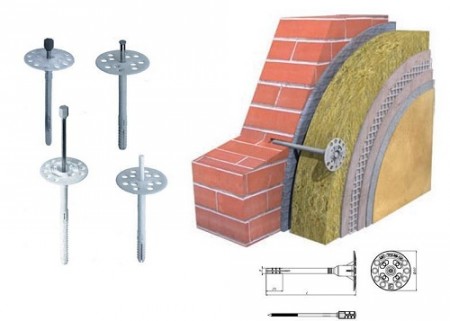

dowel attachment

Dowels foam is fixed mainly to the ceiling, when you need a reliable grip with the base. With the help of glue alone, a ceiling foam can be attached, which again comes into fashion. Fastening by dowels and glue is simultaneously used if ceramic tiles or other heavy finishing material are placed over the foam plastic. This type of fastening is used mainly for outdoor work.

fastening of foam with glue

With the help of sheets of polystyrene it is possible not only to insulate the room, but also substantially to level uneven walls. For work, a special dry glue, or gypsum plaster is used. Before starting the installation work, the surface of the wall must be thoroughly primed for reliable adhesion. And the walls should not be heavily curved, otherwise it will inevitably affect the finish finish. The easiest way is to glue a piece of foam with a mounting foam. With this composition, the foam is adhered to almost any surface, quickly and qualitatively.

application of polyurethane composition

The use of this composition makes it possible to glue the foam plastic very simply and at the maximum speed, and even to save at the same time. The polyurethane composition costs about the same as the dry mix, but the mixture still needs to be prepared, and the composition is sold fully ready for work. Using polyurethane, do not forget about washing, as the composition dries very quickly. A small disadvantage of polyurethane mixture can be considered the impossibility to hide small uneven walls. When using a dry mix, this is easily done by applying a thicker layer of glue. But this small disadvantage more than covers the numerous advantages of this material.

Cutting foam. Practical tips

Many people, especially those who first decided to work with polystyrene, a natural question arises - how to cut it? And that not only quickly, but also qualitatively, smoothly. The density of the foam can be different. Polyfoam with high density, harder, is processed well, but with soft problems begin - it starts to "loach", crumble and break during processing. In addition, the thickness of the foam can be different, so it is impossible to give one specific advice, but we will still try to cover this issue.

Soft foam is quite convenient to cut into pieces with a stationery knife. With polystyrene, he handles quite well. However, this knife has a very thin blade and can not be cut carefully by a thick piece. Thick sheets can be cut with a sharp sharpened long knife with a strong blade, and it is desirable to heat the knife strongly.

If you do not need a perfectly smooth and neat line of the cut, you can try to cut the foam with a saw with wood with small teeth. Some builders use to remove foamed plastic with an electric grinder, but this tool strongly tears soft material, and it will not be possible to cut off a neat piece.

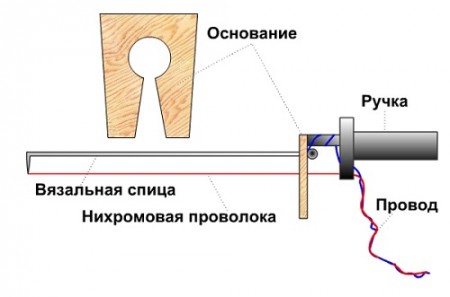

You can achieve an almost perfect cut using a red-hot nichrome wire. To do this, you will need to assemble a kind of primitive machine, as shown in the figure.

The wire is pulled strictly vertically, and a current of 12 volts is passed through it. Folk craftsmen often adapt for this purpose a transformer from an old TV, devices for recharging batteries, and generally any transformer with suitable voltage. To the electrical network it is necessary to connect a rheostat or alternating resistance. If you are at least superficially familiar with the basics of electrical engineering, then you will do it without difficulty. The current must be kept under control, because if the wire heats up, it will, firstly, burn quickly, and secondly, the foam plastic begins to melt severely on the cutting line and may even catch fire.

This method is good in that it is possible to cut foam plastic not only in a straight line, but also to cut figured elements.

Another option for cutting foam - with the help of a Bulgarian. At the same time, you need to use the thinnest disk that you can find. However, with the help of the Bulgarian, it is also impossible to achieve an ideal cut - the result will be almost the same as with a jigsaw.

In general, polystyrene can be cut with any of the above methods, the only question is how you need to cut the foam. If very carefully - use a nichrome thread, if not - choose any suitable tool.