After all the works connected with the construction of the house are finished (the foundation is filled, the basement is framed, the walls are removed, the roof is blocked), you can start the construction of the blind area. In fact, the blind can be done after the walls have been laid. But experts argue that the most appropriate time is after the completion of construction work, because the decoration of the blind area is considered a finishing work. When the plans are to perform work on the lining of the socle, then the blind is made after decorating the socle.

Content

Is it obligatory to make a blind area

Experienced builders advise: even with a budgetary construction with planning no big financial waste, you should find an opportunity and allocate the necessary amount for construction of the blind area. Work on its construction must be completed before the fall of the storm. In this case, you can be sure that the house will pass the winter cold without problems.

Blinds carry much more essential functions than it might seem at first glance:

- it is one of the important decorative elements, its construction is considered the final stage of outdoor decoration;

- it is the main protection for the foundation, preventing the penetration of moisture inside (melting snow, precipitation), properly decorated blind area promotes the diversion of water into the sewer;

- it prevents the freezing of the soil around the house, as a consequence, contributes to the preservation of the heat formed in the house;

- in addition, there is a guarantee that not frozen soil will not be swollen (if the indications of geodesy indicate that in this area there is a tendency for soils to swell, then the blind area will have to be warmed).

Construction of concrete area

The most often used and not difficult version of the blind is a concrete area of 60 cm wide, located on the perimeter of the house.

When performing a blind area, you must follow the following rules:

- the width of the blind should be greater than the projection of the roof (not less and not the same width as the ledge), the correct width of the blind is equal to the ledge of the eaves or the roof, plus 20 cm;

- the blind area should be located continuously along the perimeter of the house, only in this case there is a guarantee that moisture will not penetrate to the basement floor;

- the width of the blind area directly affects the improvement of the protective functions against moisture penetration;

- to equip a blind area with a slope of at least 1.5 degrees.

Concrete blind area with own hands

Blinds carry important functions and must therefore be carried out according to the rules. Before you make a blind, you need to remember that it depends on its quality:

- duration of the operational period of the foundation,

- a significant reduction in financial waste and time for repair work of the plinth and foundation,

- as well as the lack of experience after the completion of self-construction.

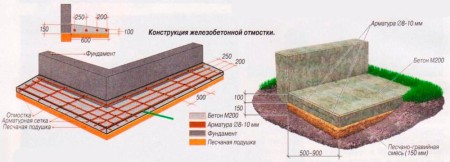

Blinds have two main layers:

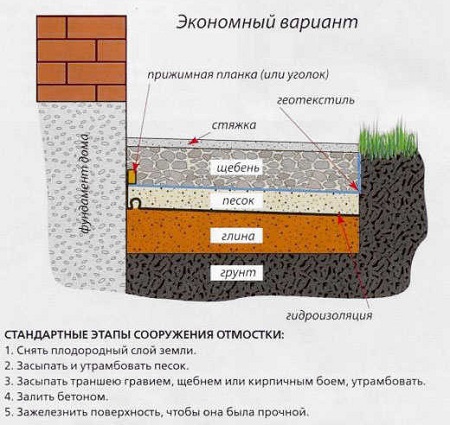

- The first, litter - is a leveled dense base for creating the main cover. can be made of the following building materials: sand, gravel (fine), clay. The choice of litter material directly depends on the intended coating material. The thickness of the litter should not exceed 20 mm.

- The second, the coating - is made of a material that does not penetrate and does not absorb water, and also does not deform under the influence of moisture. Coating can be used concrete, cobblestone (fine), asphalt, clay (this material is used for both litter and coating). The thickness of the coating should not exceed 10 cm.

Blind concrete - technology of creation

First you need to make a markup for the blind area. Then correctly calculate its width. The concrete area around the house is laid only after the soil is removed and well-consolidated along the perimeter of the building. When building a blind area, the soil is prepared precisely for the width of the planned blind area, relying on the markings produced earlier. In order to understand at what depth it is necessary to make a groove in the soil for the blind area, it is necessary to take into account what building material it will be made of. For example, when making a blind from concrete, the depth should be on the spade bayonet, that is, up to 25 cm.

In some cases, when there is a threat of damage to the blind area near the roots of growing bushes and trees, the visible root system under the removed soil is treated with herbicidal composition.

Now you can start building a wooden, removable formwork. It will require boards with a thickness of more than 20 mm.

On the compacted soil layer, put clay, medium thickness, level and compact well. Now a layer of sand, about 10 cm thick, which is also diligently compacted. For a more compact tamping, you can pour the sand layer with water. The water should be a moderate amount, do not forget that under the sand is clay and do not need to allow it to get wet. When compacting sand, special attention should be paid to parts located directly near the foundation.

Now it's turn to rubble. Its layer should be 6-7 cm.

In order to strengthen the blind it is necessary to reinforce a special grid designed for this purpose. Reinforcement will help to withstand the stresses on tension and compression.

Now you can make out a compensating (temperature or deformation) seam. It is located in the place where the junction and the socle are connected. This seam will prevent the destruction of the blind area and the socle when the ground settles. When sinking, the blind area will sit on the seam and do not deform the base. The width of the seam should be about one and a half cm. The filling of the seam can be done with the following materials: gravel (fine) + sand, mastic, bitumen, several layers of roofing material. You can also fill the seam with foam polyethylene (tourniquet), with a diameter exceeding the width of the seam by 25%. Only in this case, the tourniquet tightly fills the seam.

Filling the concrete area, at a distance of about two meters from each other, it is necessary to have temperature seams. They will protect the concreted area from possible ruptures when exposed to low temperatures. To do this, use rails of wood, put on the edge. The location of the top of the rack must coincide with the concrete surface. In order to protect the slats from rotting, they need to be treated with a special compound (bitumen mastic, used oil and so on). Deformative sutures must be done in the corner parts of the house.

The next stage in the construction of the blind area is laying and compacting the concrete mixture. The base is leveled using beacons - pre-installed wooden rails.

The thickness of the concrete area should be from 8 cm - this layer of high-quality concrete can withstand serious loads.

Concrete for blind areas is usually prepared with the addition of plasticizer, its presence improves the quality of concrete and gives it some plasticity, which is very important when performing laying operations. The greatest degree of strength of the surface of concrete can be obtained through ironing. The ironing done by the wet option will increase the moisture resistance of the blind area to the maximum level.

The final stage of work is to cover the surface of concrete with a cloth, which will have to be periodically dosed. Such a process will prevent the drying of the concrete to the final solidification. In case of registration of the blind area during the period of active precipitation, the area can be not humidified additionally. Everyday rainfall will do its job.

At the end of the week, the concrete area made of concrete is made according to all norms, it will be ready.

Concrete area and its repair

When the socle, foundation and scaffolding are made qualitatively, a long period of time the occurrence of problems will be ruled out.

There are cases when cracks or defects form on the surface of the blind, occupying a decent area.

To get rid of small depressions, you can use the composition of cement, prepared in a proportion of 1: 1. More impressive excavations need to be cut down to the bottom and cleaned of contaminants. After that you should use the mastic prepared in the following ratio: 70% bitumen, 10% fine slag, 15% asbestos. After filling, the cracks are sprinkled with sand.

When the deformation of concrete is very visible and accounts for more than 50% of the total area, it is restored with new concrete. Before this, the renewable area is cleaned of dirt and primed. As a primer, a cement solution prepared 1: 1 is used. Then pour the necessary amount of solution and level it. Then follows the wetting of the concrete layer until the final hardening.