The tree is a truly unique natural material, endowed with excellent decorative and operational qualities. Due to its aesthetic and ecological safety, a wide range of textured and color solutions, light weight and ease of processing, increased strength and durability, wood is successfully used massively in the construction of residential structures, modern interior decoration and the creation of original decor elements.

Modern parquet cover and its features

Parquet - this is the most common and sought-after finishing material for decorating the floor surface of a residential and office space. The quality and durability of natural flooring is determined not only by the quality and performance characteristics of the raw materials, but also by the technology of laying the parquet or parquet board.

Therefore, if you seriously think about finishing the floor with parquet, we advise you to familiarize yourself in detail with the technology of its installation and the features of the operation of the parquet flooring.

As a material for the parquet floor is a parquet board, consisting of several layers of wood. Thanks to the special technology for manufacturing parquet, all layers are assembled and glued together into a solid monolith. The fibers are perpendicular to each other. For the production of the lower two layers, strong and cheaper types of wood are used, but the upper layer, which is the main focus when walking, consists of lamellas of expensive wood species. This feature gives the floor covering a high reliability and the possibility of long-term operation.

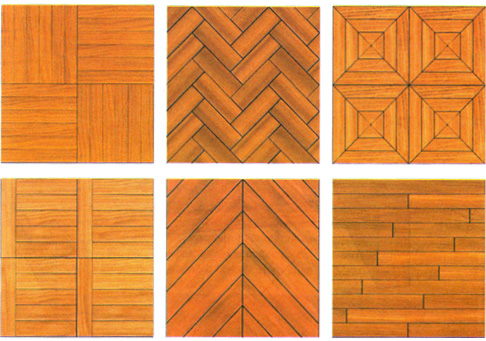

Today, the market of building and finishing materials offers an extensive selection of piece parquet from absolutely any kind of wood. The variety of textured and color solutions, every possible arrangement of lamellas (in the form of braids, a Dutch pattern, a Christmas tree) will allow you to realize any design fantasy.

Technology of laying parquet

Before you decide on the need to lay parquet, we remind that wood is a "living" natural material, the quality and durability of which is determined by the temperature and humidity level in the room, which means that it is advisable to lay parquet only in the premises where you yourself you can adjust the temperature and humidity level.

A low level of humidity in the room threatens the moisture loss of the parquet board. Due to shrinkage, the shape and size of the strip deform, and crevices form between the boards.

With a high level of humidity, the board will absorb and swell it, and increasing in size, forms the effect of "boat".

The optimum conditions under which the finishing material retains its original appearance and humidity in 9 + 3%, if the temperature in the room varies from +18 FROM up to +24 ° С, and humidity of air does not exceed 40-60%.

Today you can lay parquet in three ways:

- laying of parquet on screed;

- laying of parquet on logs;

- parquet laying on the floor

laying of parquet on screed

This method of laying a parquet is advisable to use if, when measuring the surface of the base floor, you have detected unevennesses of 2 cm.

1. Before carrying out tie-up work, you will conduct waterproofing of concrete floors using a thick polyethylene or foil polypropylene film. This process will allow you to avoid penetration of the solution to the lower floors. Drying of cement screed can take you 4-8 weeks depending on its thickness.

2. At the next stage, install a sheet of plywood 10-20 mm thick. Pre-dried screed is ground and treated with glue. Square sheets of plywood (from 40x40 cm to 75x75 cm) are laid like a brickwork, not forgetting to leave gaps between the sheets of 3-5 mm and up to 10 mm - from the edge of the sheet to the wall surface. These intervals are then to be treated with a sealant. Fix the plywood on the screws through the pre-made holes, drowning the screw heads for 3-5 mm.

3. Thoroughly polishing the plywood, proceed to the construction of parquet with a spatula and special glue. Using mechanical or pneumatic equipment, perform the alignment of the strap along the edge to the edge. Such simple manipulations will allow you to remove excess glue and create a uniform device of the slats during the polymerization.

4. After 5-7 days, you can polish the parquet and apply the putty on the color of the parquet board. To obtain such a putty mix the parquet dust with a special liquid.

5. After finishing the polishing of the parquet, treat the floor covering with varnish. Avoid drafts and work air conditioners, primruntuyte, and then carefully polish the parquet and apply 2 coats of finishing varnish.

6. At the last stage, fix on the glue or nails the parquet skirting, allowing to disguise all the roughness of the floor near the walls and hide the electrical cable and wires.

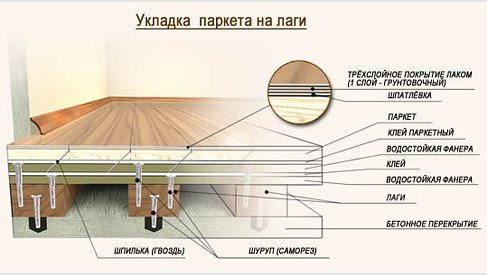

laying of parquet on logs

In comparison with the previous method, the flooring of the parquet coating on the logs excludes the carrying out of dirty works and saves considerable time. Using this method, you will be able to lay any communications under the cover and increase the level of heat and sound insulation by installing a layer of insulation between the lags.

Logs are wooden planed bars, impregnated with an antiseptic, having a section of rectangular shape 50mm x 70mm and humidity 12%.

1. Have logs on a concrete foundation strictly perpendicular to the floor covering. The axial distance between the lags is 25-30 cm. The fastening is made using dowels or screws evenly at a distance of 50 cm from each other. Having established the lags, you have to align them on one level.

2. Then install 1 layer of plywood on the logs, then on top - another one. Watch out for the total thickness of the plywood! It must be at least 20 mm.

3. Then the plywood is ground and the parquet is laid.

In more detail the process of laying a parquet on the lag is shown in a video on youtube.

parquet laying on the floor

This method is the most simple and economical, since it excludes the time costs for creating and drying screeds and installing lags.

"Parquet cake" includes:

"Parquet cake" includes:

- 1 adhesive layer on the roughing floor,

- 1 layer of plywood,

- 1 layer of glue on the plywood,

- parquet flooring,

- putty and 2-3 layers of varnish.

At the same time, the quality of the floor covering directly depends on the quality of the black floor, which should not creak and move underfoot.

Only with strict adherence to the technology of laying the art parquet and its correct operation, you will be able to enjoy this amazing natural flooring for a long time.