It is known that the freezing of walls subject to enclosing structures in violation of the thermal regime of the house. Visible freezing is an alarming signal about the onset of a destructive process, which must be quickly and successfully eliminated. What should we do: wait for the repair team or start repairing the defect with our own hands?

Content

The reasons for the freezing of walls

Among the common defects in buildings and structures, freezing of walls is the most common. The paths of the passage for cold air through the walls from outside are sufficient.

The reason for the freezing of walls in a panel house, whether wooden or brick, can be:

• a significant moisture content in the wall material, providing a super saturation of the surface

• lack or lack of ventilation, which can ensure the drying of the walls

• Insufficient heating

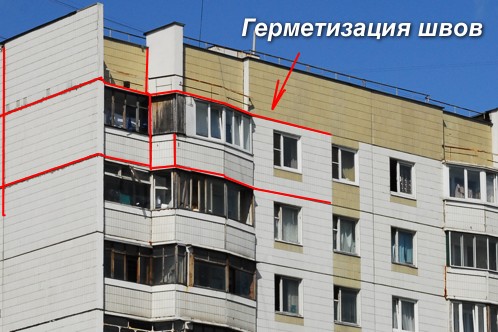

• poor sealing of joints or lack of it.

The freezing of the walls of the house can be facilitated by several factors or sources. For example, the defect of the seam between the plates outside and wetting the walls from the inside.

Before proceeding with the liquidation of freezing, it is necessary to carefully determine where cold air comes from.

Methods for determining freezing

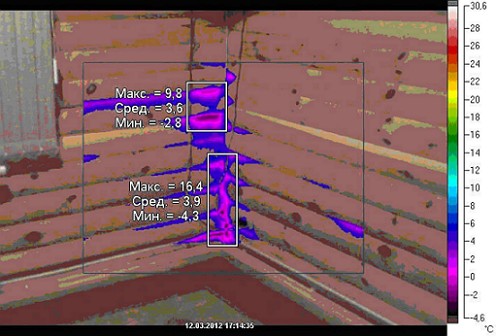

Available methods for determining the freezing of walls are a visual inspection and use of a thermal imager. Naturally, the visual definition will not provide reliable data on leakage of structures exposed to moisture and freezing.

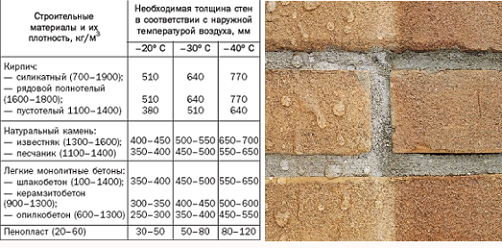

A thermal imaging survey conducted by specialists will fully provide reliable information on the state of inter-panel joints in a multi-apartment building. Recall that between the building material, from which the walls are built, the air temperature and the thickness of the walls of the house, there is a relationship that can not be canceled.

Helpful Tips

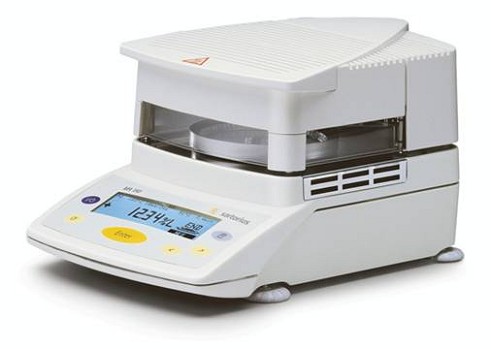

Professional determination of the degree of freezing and evaluation of the degree of damage is based on the analysis of the result of sampling. Sampling is made by the thickness of the panel or the joint of the heater. Defective areas reveal and assess the state of the interfaces. Based on the correlation analysis, the permissible moisture value of the sample is calculated.

In case of exceeding the permissible value, the joint of the structure requires dehumidification and sealing of the defective area. It is recommended to seal the plate around the entire perimeter, despite the presence of one or more local points.

Types of freezing and formation of cold bridges

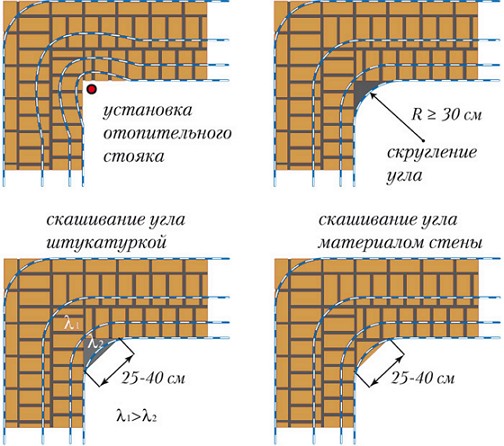

A common type of freezing is local focal, affecting inter-panel joints, corners and joints of corner rooms, especially in multi-storey apartment houses.

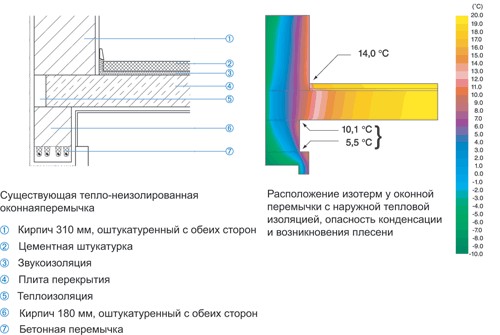

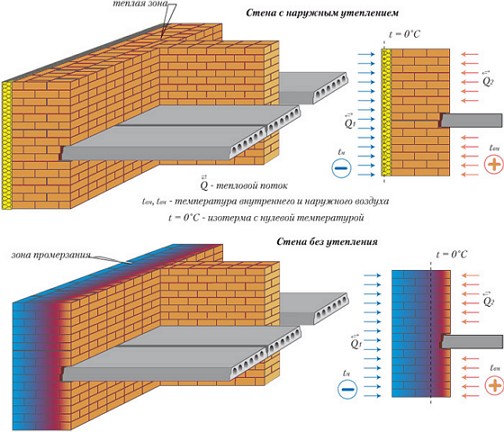

Let us say that the causes of glaciation in violation of waterproofing, vapor barrier and heat insulation of seams. This formation of "cold bridges" is characteristic for the freezing of the brick wall and the panel wall.

Systemic wetting of walls and destruction of the concrete layer leads to damage to the heat-insulating layer and the formation of voids in the corner joints and seams. Moreover, the depth of freezing of the walls begins to increase rapidly with time.

which promotes the formation of cold bridges

The reason for the formation of "cold bridges" are:

• the opening of joints and the formation of cracks of high degree of expansion between the panels

• The thickness of the partitions does not correspond to the project normative

• destruction of the foundation or facade due to non-compliance with construction technology

• emergency condition of the house or apartment (the flow of the roof and walls).

However, the reasons for the formation of problem areas can be abound. The main thing is to begin to force the freezing factors of walls, causes and methods, the elimination of which is regulated by regulatory documents.

Methods for eliminating freezing

Eliminate the freezing of walls by several methods.

Methods for eliminating the freezing of walls are divided into internal sealing of apartment seams and external insulation, using innovative technologies.

internal insulation

For the internal type of warming of the freezing wall, it is preferable to use the method of Warm plaster, which is distinguished by the ease of applying the working solution, quick setting, high vapor permeability and thermal insulation properties. For your reference, the layer of Warm Plaster with thickness up to 50 mm guarantees lower condensation, corresponding to a healthy microclimate.

Internal corner warming perform in several stages:

• walls and corners are peeled off from plaster or wallpaper

• produce barbed and stitched (cross section 20x20) corner joints

• the angle is dried and milled

• the angle is frosted and after the final setting of the foam, followed by removal of the excess heat insulation.

The internal method of warming is more economical and technologically simple. You do not need to resort to the services of industrial mountaineering.

How to make the insulation of a wooden wall, shown in the video.

How and what to produce external insulation

materials for frost protection measures

Let's remind, that the traditional materials intended for protection against freezing are:

• polyurethane foam

• expanded polystyrene and penoplex

• erection of an internal wall or a partition with an interlayer from a heater

• primer for walls from freezing armor

By the way, materials for external insulation of seams are recommended to be chosen, taking into account good adhesion to the concrete surface, high elasticity and high strength characteristics.

At present, there is a certain tendency to use liquid suspensions based on acrylic polymers and synthetic rubber to eliminate freezing.

The application of a liquid heater with the freezing of wooden walls replaces the existing insulation.

technology of external insulation of walls

The existing technology of warming the walls from freezing is known and available for hand-made execution. As a useful advice, we will show that the most popular, practical and economically profitable are the Wet Facade

http://svouimirukami.ru/dvuhetazhnyie-doma/mokryj-fasad-mokryj-fasad-tehnologiya-montazha-poleznye-sovety.html

and Warm seam.

warm seam

To carry out repair work to eliminate the freezing of defective areas of external joints of panel houses, it is recommended to follow the technical requirements of VSN-119-75 "Guidelines for the sealing of joints for the repair of full-assembled buildings for the production of repair work" paragraph 4.2.

To eliminate leaks that entail freezing, re-seal the inter-panel joints with mandatory opening of the joints of floors located above the site of leakage along the vertical. Unfortunately, the teams of builders from ZhEKov do not adhere to these rules. It is enough to look at the outer seams of the house in the form of separate patched fragments.

How to prepare interpanel joints, shown here.

The features of the Warm Seam technology consist in filling the voids of the defective area with a wiltherm mounting foam with a tubular insulation from the outside. When applied, the foam, expanding, fills the existing voids and cavities. More detailed information in this video.