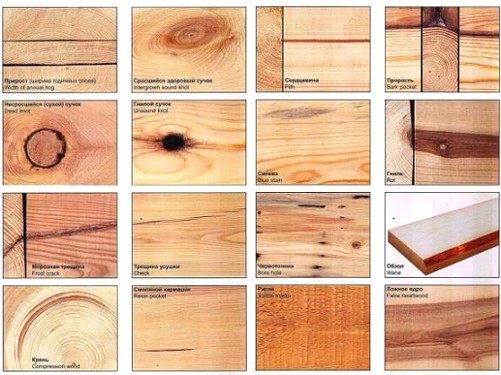

It is known that the professional choice of sawnwood is rather complicated when buying. Especially when you want to choose a product cheaper. But the choice of boards does not tolerate fuss, let alone an amateurish approach. Therefore, consider carefully the plank imitation board. You will discover a lot of cognitive: resin pockets, non-strog and wormholes. Then the false beam will not look fake and you will be able to make the finish with wood.

Content

Choosing a board imitation bar

Almost everyone knows about the attractiveness of a wooden house from a bar. The majesty of the house made from environmentally friendly sawn timber is confirmed by the main qualities of wood: good thermal insulation, durability, soundproofing and medicinal properties of the wood species.

The only thing that confuses the choice of wood is the solid price of the bar. A comparatively new sawn timber is imitation of a bar, which visually does not differ from the original product, the detailed information is contained http://faneramonolit.ru.

Products imitating a bar have several names:

• planking board

• panels under the bar

• falshrus

• lining.

We are talking about the same lumber - a planed board, with ends equipped with a special profile and a locking system.

However, the variety of names did not prevent the wooden product from gaining popularity among developers.

Choosing a board for imitating a bar for exterior and interior finishing is recommended for assortment and size.

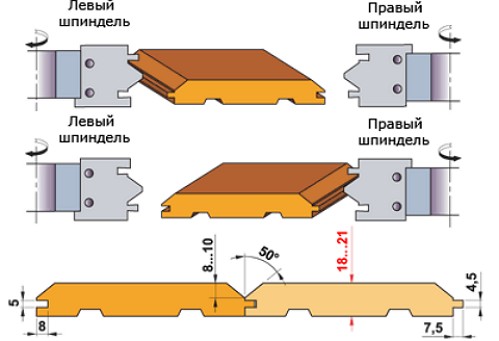

Profile of beam simulation

Exaggerated profile of beam imitation resembles the profile of a wooden lining. Board simulating the bar is an industrialized product, the interconnection of which is carried out with the use of grooves and tongues.

When choosing a board for imitating a beam, it is recommended to understand the assortment of lumber.

Nomenclature of assortment: without a hitch

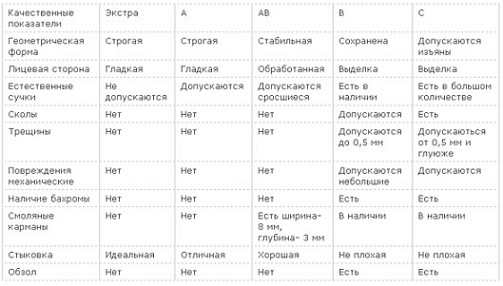

Nomenclature of the assortment of the board imitating a bar is as follows:

• extra class It is represented by a board with a smooth surface that excludes defects: rot, wormholes, knots and a sprout. A small amount of resin pockets with a size of 20x3 mm and end fissures of 30x0.5 mm is acceptable. At visual inspection, a slight overlook and non-strog is allowed only from the back side.

• to grade A carry the board without dropping knots and putrefactive lesions. Admissible a small number of end cracks that are not through-through, resin pockets and chips only on the underside of the groove. Non-strog is only valid from the wrong side.

• variety B represented by a board without putrefaction, perhaps the presence of dead knots of dark color with a diameter of not more than 10 mm and wormholes up to 5% in batch. There may be a non-rigidity on the underside and an invisible look or fading.

• variety C allows the presence of wood defects: dead knots, longitudinal cracks 30x3 mm, sprouting and rotting, as well as defects in planing from the visible side and survey.

Thus, it can be concluded that the proposed board for simulating the beam at a price will in most cases be Class A or B. An extra class of a product can be considered a rarity in the sawnwood market.

How to determine the quality of lumber will help you video.

Dimensions of the board

The dimensions of the simulation board manufactured by the industry can be:

• length 3.0-4.5 m, width 0.105 m and board thickness 0.015 m

• imitation of a bar without a knot: length 3,0 - 4,5 m, 0,135 m and 0,020 m.

• a false beam length of 4,0 - 4,5 m, a width of 0,140 -0,185 m with a board thickness of 0,020 m.

The board thickness can be from 16 to 30 mm according to GOST 8242, which regulates the production of profiled wood finishing material.

Due to the variety of assortment and sizes, it is possible to choose a suitable board for simulating the beam, the dimensions of which will avoid trimming and waste.

Moreover, when manufacturing the entire range of sawn timber, it follows a single technological process.

Finishing board imitation bar

The choice of wood for finishing should be justified, because wood materials. except for advantages, have some drawbacks. With the passage of time and with improper care, the wood trim can be rotted, insects and damaged by moisture.

In addition, the produced external or internal decoration under the bar looks monotonous for a considerable period of time. If you are ready for this, then finish the board with a block house imitation of the beam or another possibly with your own hand.

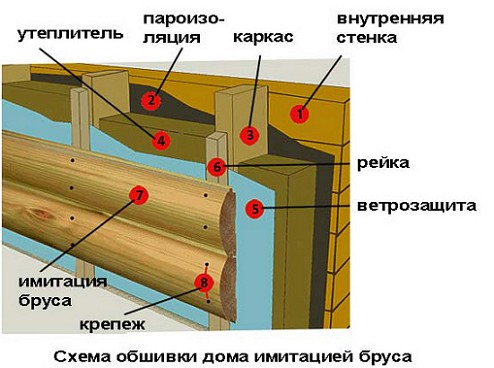

The board board can be considered universal because it is applicable for finishing the internal and external surfaces of walls made of brick, stone, wood and concrete.

And, the type of walls does not matter. These can be load-bearing walls or frame partitions. The most demanded is the installation for the skinning of frame walls.

Imitation of the beam with a wide profile is used for exterior decoration, for the visual increase in space, the inner space is covered with narrow panels.

Stages of installation of products of imitation of a bar

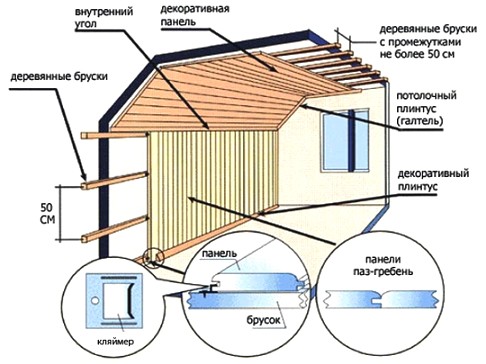

Finishing "under the bar" is made according to the following algorithm:

• Calculation of the surface of the upcoming finishes and fastening elements

• selection of the type of panels or boards, according to the calculation scheme

• installation of the flooring with the selected step for the finishing material

• installation of finishing panels or boards simulating a bar.

Before the installation of boards of imitation of the beam, the walls are leveled using a crate, which compensates for existing irregularities. The cladding is erected from brusks or metal profiles in steps of 60-80 cm.

Then calculate the total number of panels (boards) taking into account their width and the lock part.

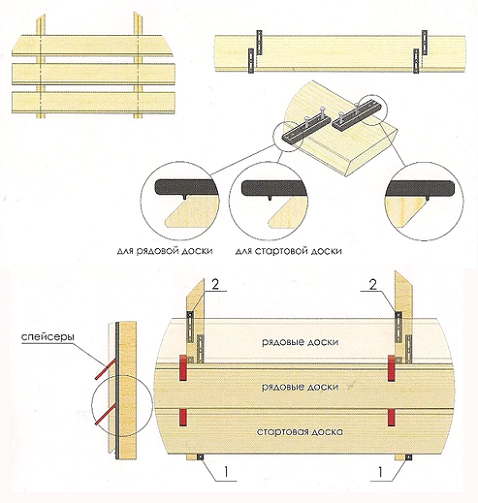

For fixing the boards, preference is given to: kleimers and spacers.

Modern technologies for mounting the simulation board are presented here.

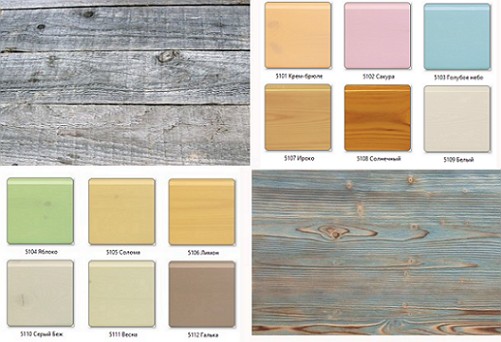

Painting coatings simulating the timber

Finishing the imitation of the timber is impregnation, coating with paint and varnish.

The coating can be made in a transparent composition (glaze, aqua-varnish, impregnation with oil and coating composition) and opaque (enamel, acrylic and water-dispersion paint).

Apply a varnish-and-paint coating to the board of imitation of the beam with the outer (3 layers) and internal (2 layers) finish in the traditional way.