Concrete staircases are very durable and have almost unlimited lifespan - in other words, a staircase made of concrete can serve as much as the house itself. Additional strength is provided by steel reinforcement inside concrete structures. Thanks to the reinforcement, concrete does not crack and does not crumble. Interstitial concrete ladders according to the manufacturing method are divided into several types: prefabricated, which are assembled from pre-fabricated parts and solid monolithic, which pour out of concrete directly in place. The only significant drawback of concrete stairs is an extremely gloomy and unattractive appearance. But this can be corrected with the help of additional decorative details - handrails and fences, as well as a variety of finishing materials. Of course, if your house is built by specialists, such as OOO StroyProekt - You do not need to worry about finishing, as all the work will be done qualitatively and reliably. But if you do everything yourself, then we recommend reading this article. In the framework of this publication, we will talk about how to trim the concrete surface of the interstore ladder with wood, what materials to use, briefly describe the process technology and pay attention to errors that should be avoided.

Content

Some Common Errors in the Cladding of a Concrete Staircase with Wood

Let's start with a common misconception. Most developers believe that the biggest cash costs are associated with the pouring of the stairs. We dare to assure you that this is not so. Very often, the finishing of a concrete staircase with wood costs considerably more than the staircase itself.

And in order not to increase the already high cost of cladding works, avoid the following errors:

- In no case do not fix the wooden parts directly on the concrete surface - this finish will not last very long. It is necessary to use a substrate of plywood.

- It is not necessary to save on the thickness of wooden parts - a minimum of 3 centimeters. Wooden parts will need to be ground, level the surface and do the veneering.

- Do not use lacquer or paint, which completely hide the texture of the tree, you will spoil the appearance of the stairs.

- Before you start the cladding, carefully clean the concrete surface of debris, otherwise the adhesion to the surface will not be strong enough.

- Do not rely solely on fixing with glue - always use dowels.

- Do not try to save on paint and varnish materials, buy only a moisture resistant varnish. Steps need to be opened with a varnish minimum two or three times, with drying of each layer.

- Quite often the owners of two-story country houses want to restore the old concrete staircase. And although the restoration work is more labor-intensive, but the result will undoubtedly please the owners, the steps will look like new ones. Finishing the stairs with a tree is not as difficult as it might seem at first glance.

Required Tools

So, we need:

- Electric drill or screwdriver.

- Hammers of different sizes.

- Electric jigsaw.

- Hacksaw on wood.

- Building level and plumb line.

- Sanding machine.

- Frazmashinka.

After all the necessary materials have been bought: wood, plywood for linings, sand, cement, glue, screws, dowels, paint and varnish materials, you can start work.

Cladding installation process: step-by-step instruction

- To begin with, thoroughly clean the concrete surface of the steps from dust and debris, make sand-cement mortar. Clean steps are treated with a mixture of PVA glue with sand. The layer should dry completely, it takes about 5 hours.

- Take a spatula and level the surface of the steps with cement mortar, filling all the potholes, cracks and irregularities.

- While the solution dries, you can deal with treads and risings. To ensure that the lining of the stairs lasts for a long time, only hardwoods should be chosen.

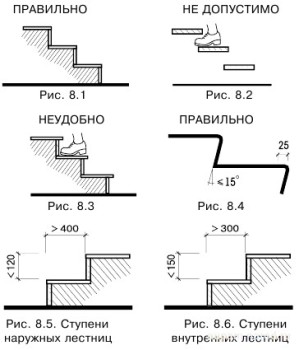

- The standard width of the stitches is 27/32 cm, the risers are 15/18 cm.

- Cooking and mounting these elements is necessary, based on the features of the march of your stairs.

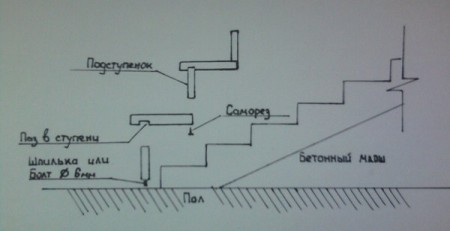

- The risers and treads are attached with screws as follows. With the help of a milling machine a groove is made, then the riser is attached to the tread with the lower edge, flush with the lower part. The upper edge of the tread is inserted into the groove from the back side. Optimal dimensions of the groove: width - 2.5 cm, depth - 1.5 cm.

- This process can be greatly simplified and accelerated if we collect a "ladder" from several steps and risings. At the same time, it is necessary to use a corner made of metal from the side of the tread.

- It does not hurt to make additional insulation of the steps. For this, it is possible to use a conventional polyethylene having a thickness of at least 3 mm. It will provide sufficient protection of concrete and wood from moisture, and, in addition, will act as a soundproofing device, significantly muffling the sound of footsteps.

- The lining of the concrete ladder with wood starts from the lowest riser.

- On each workpiece, mark and drill two holes on each side.

- Each part is installed in the groove of the previous one and is set up strictly vertically. At the end of the staircase with the help of a metal corner or a board the last step is set.

- Do not screw the screws until they stop completely, until the entire structure is completely mounted. At the end of the installation work, you should carefully check everything, and only after that you can tighten the screws to the end.

- After that, you can do the finishing of the handrail, if this operation is planned. In this case it is desirable to use the same wood species as for finishing stair flights.

- Straight sections are easy to mount, complexities arise when creating intricate turns - "snails", sharp bends and kinks.

- The handrail in the corners is mounted by cutting the parts at a certain angle with subsequent gluing, and then fastened with screws to the base. To cut the line was smooth and without torn edges, you need to use a hacksaw with small denticles. When the finish of the staircase is finished, the joints are gently squashed and then polished.

- The last stage of finishing works - grinding and covering the steps with several layers of varnish. As we already mentioned above, it is strongly discouraged to save on paints. Buy a high-quality varnish, and do not forget to carefully study the instructions. Cover the wooden parts in two or three layers. After applying each coat of varnish, you should wait until it completely dries.

- Varnish try to pick one that he does not hide, and emphasized the texture of wood, and gave your stairs an additional attraction.

The choice of wood as a material for cladding

Any owner of his own house will try to do everything possible to make the staircase in his home not only practical and convenient, but also beautiful. For this, it is necessary to select the grade, color and shade of the wood correctly and tastefully. People who can afford it, in pursuit of originality and spectacularity spend furious money on rare, exotic breeds brought from afar to be "steeper than neighbor's."

But it is not necessary to finish your steps with ebony wood from the monsoon forests of India - you can buy quite good, beautiful and high-quality material in your region.

Oak

Recognized as a favorite among finishing materials. Durable, beautiful, and, most importantly, affordable material. Has a pronounced texture and a pleasant palette of hues - from soft yellow to blood-brown and brown. Oak finish will make any staircase turn into a beautiful and respectable piece of furniture.

Larch

Widely distributed in the territory of Russia the material, you can buy it without any problems, and it is inexpensive, several orders of magnitude cheaper than oak, and there is little inferior to it in quality. It is quite strong and reliable material with a long service life.

Ash

Its cost compared to oak is also much lower, and the ash wood is stronger than oak, it has a beautiful texture, a pleasant range of colors, a great variation of shades in light and dark colors. Ash - the material is available, there will be no problems with its purchase.

Beech

Very beautiful and durable material. Has a continuous uniform texture, very soft pleasant color, often used as a mahogany imitation. The cost of beech is somewhat higher than that of larch and ash, but it is still affordable material.

Important point: do not be tempted by the beautiful structure and low price of materials such as pine, spruce, linden, etc. These materials are very easy to process, and the final result looks good, but only they will not last very long - the lining of the staircase will very quickly lose its original appearance.

What you should pay attention to in the course of facing works

- First of all, try to make the color scale of the steps and the floor in the room coincide.

- Wooden lining of the stairs should not yield to the strength of the floor covering. Ideally, you need to use the same wood species.

- The thickness of the lining material should be not less than 3 centimeters.

- Do not start the finishing work before the concrete surface is completely cleaned and leveled.

- The gap between the marches and the handrails of the ladder should be within fifteen centimeters, but it is not worth doing less than seven and a half centimeters, this is the minimum size. According to the rules of fire safety, the gap can not be made smaller, because through it a fire hose must pass freely.

- You can not make steps of different heights, because the design will be very difficult to align. Use of glue and putty is not recommended for this purpose.

- In the height of risers and treads, deviations of max. 1 cm are permissible.

- If there was a need to level the heights, you need to use a strong concrete mixture and make the reinforcement of the step.

- Even the strongest facing material will not last long if the concrete foundation is not firm. Concrete under regular loads will begin to deteriorate, which in time will lead to complete uselessness of the entire structure.

- The timbered staircase looks very impressive in combination with elements of forging, as well as glass and chrome parts.

- Try to arrange balusters, bolt, railing and steps in one color scheme.

- Do not start the finishing work before the main repair is completed in the room. If everything is done carefully, after the facing works there will not be a lot of garbage left.

- If possible, be sure to use the services of professionals. At least, consult with the designer, he will help you choose the optimal solution specifically for your interior.

- If you are not confident in your abilities, hire workers who have the necessary skills and have a professional tool, they will make the hull much faster and better.

Conclusion

The most modest budget interior can be decorated with spectacular details. Heavy and unattractive concrete staircases were left behind. Today it is customary to create practical and beautiful designs.

If you are confident in your abilities, and have experience in the field of construction and finishing works, you can start safely. But, do not count it superfluous to recall again: do not save on the services of specialists, when you are not sure of your abilities, remember the well-known proverb - miser pays twice.

In the video below, you can find additional information on this issue.