Beautifully executed brickwork is distinguished by an impeccable line of seams. The strict geometry of jointing can be confidently called the final chord of the construction of the masonry. However, it is necessary to make a screed by the rules, clearly and smoothly leading a special knife. How is it recommended to do the shaving so that the hand does not flinch?

Content

Features of brick masonry

Brick masonry when erecting partitions and walls of the house is performed according to a certain scheme - dressing. Bandaging allows you to build a wall with a uniformly distributed load over the entire surface.

At the end of the process of erection masonry made of bricks, it is planned to make the seams. The following factors influence the final result of erection of brickwork:

• size and color of bricks

• Seam configuration, finish and color

• Qualitative alignment of the masonry seam.

Qualitative alignment and sealing of the seam is an obligatory measure. For finishing works of masonry seams use such techniques:

• compaction and plastering.

When sealing the masonry joint, the molded or plastered seams can have triangular, rounded and rectangular profiles. The type of profile depends on the depth of the knife room for embedding into the seam and its slope angle when working.

Recall that, according to SNiP, the size of the seams of brickwork is: for a vertical seam 8-15 mm, for a horizontal joint 10-15 mm.

Types of brick masonry

There are the following types of masonry joints:

• flush (rectangular to trim)

• rectangular recessed

• concave semicircular

• beveled.

The flush joint is the most commonly used type of joint seal. The technology consists of filling the seam with a solution, then cutting off the surplus using a special knife and then processing the seam with a brush with a long hard pile. The flush edge is distinguished by a clearly defined seam line. The depth of the seam reaches 5 mm.

Rectangular embroidered screed is used when creating decorative masonry trim. Technologically, the cutting involves the initial removal of mortar from the joints, and then the subsequent filling with a new solution (depth up to 6 mm) and compaction with the rounded end of the nagel.

The concave semicircular scraping has a characteristic profile, which is created using a semicircular knife while cutting the surplus solution from the seam. The seam has a depth of 4-6 mm.

The oblique view of the screed is based on the specific position of the crocheting knife, pointed at an acute angle when cutting the solution. For these purposes, use sharp sharpened knife, which allows to lower the instrument into the suture material to a depth of 4 mm.

Naturally, it is possible to produce the embroidery only with the use of a special tool.

Which tool is used for jointing

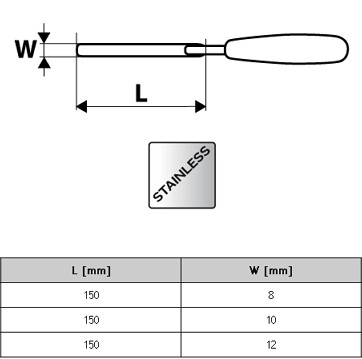

The hand tool for embroidery is a trowel with a long handle. Trowels for masonry joints can have a flat, semi-circular outer and inner working part with a width of 8 to 12 mm.

The end of the trowel knife forms the seam profile on the masonry. The tool for embroidering the seam is made of steel.

Grout solution

Mortar, for example BASICS BRICFORM T, is designed for masonry of brick, which has an average water absorption.

For the veneer use a ready masonry mortar, which has a consistency of moist soil. Composition of mortar of cement-lime mixture: 1 part - cement, 1 part - lime, 10 parts - fine-grained sand.

The water content in the expansion solutions should not exceed 15 percent.

The selected granulometric composition of the mortar mix allows simple and quick seaming, and the strength of the mortar (more than 15 MPa) ensures the durability of the joint. In addition, the composition of the solution prevents the appearance of highs on the surface of the brickwork, ensuring the stability of the suture material.

The application of the grouting solution to the work surface is carried out in a dry manner. Therefore, it is not difficult to manufacture the seam by hand.

colored suture solutions for embroidery

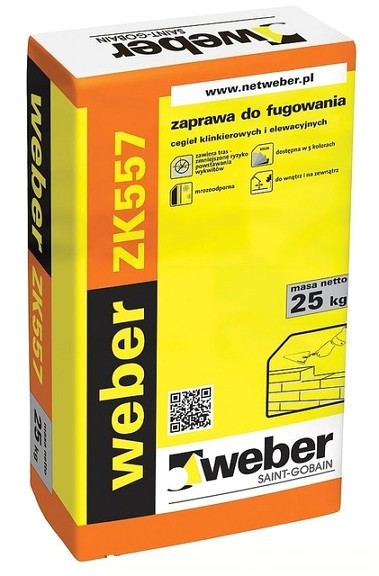

Color solutions are suture, for example weber ZK557, are used for decorative purposes for ceramic, silicate masonry, clinker bricks and blocks. The material has the same qualities as the basic solution for the shearing.

Long-term color of the joint is supported by color pigments of inorganic origin, which are part of the mixture. Naturally, the color crocheting seam can decorate any properly laid brickwork.

How to make joints by hand

It is important to remember that the process of embedding of brick seams and jointing of stone joints implies strict observance of the processing sequence. Initially, all vertical and then horizontal seams are treated. To create a smooth suture, the corners are initially constructed to track the thickness of the seam. Then pull the thread for each masonry row. Recall that the thickness of the seams horizontally is 12 mm, and vertically 10 mm.

The seam is produced by a certain technology. These are the main technological steps:

• Preparation of brickwork

• preparation of working solution

• Seam splitting using a tool.

To make the weld smooth, we recommend using a level or rule when working.

Before applying the masonry solution, the working surface is abundantly moistened with water, and after applying the casing material, the stitches are cleaned with a stiff brush.

This video will help to make the correct expansion of the brick seam.