Building bricks are the most popular material widely used for the erection of various types of structures. Even in modern conditions, when building technologies develop at a frenzied pace and new materials and technologies appear almost every day, developers in most cases prefer to erect houses precisely from bricks.

And this is not conservatism, because the building brick is a tested material, warm, eco-friendly, durable, having an attractive appearance and providing good sound insulation.

Content

Types of facing bricks

The facing brick, in contrast to the ordinary private, is more "cute", because it is more finishing than the building material. It is used not only for finishing, but also for the construction of various types of structures - decorative fences, columns, arches, etc. Sometimes used for interior decoration of premises.

The main materials used in the manufacture of facing bricks are clay, cement, limestone and various natural dyes. Facing bricks made of such "ingredients" are resistant to the most severe frost, moisture-proof and eco-friendly. There are several types of facing bricks: ceramic, clinker, silicate and hyper-pressed. Below we will consider each of the listed types of facing bricks in more detail.

ceramic bricks

It can be hollow and full body.

All kinds of ceramic bricks are made from certain types of clay. The appearance of ceramic bricks does not depend on what clay it was made from, but the quality and ability to withstand heavy loads - depends. This must be taken into account when buying ceramic bricks.

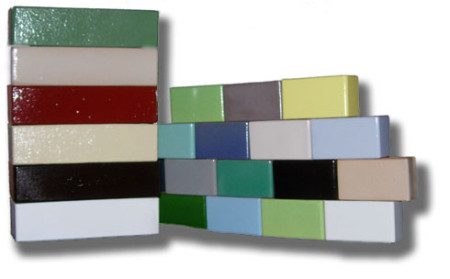

There are quite a lot of ways of decorating the front side of a ceramic brick. Classics - completely smooth surface, matte or shiny. Very popular is the brick with a textured finish, imitating, for example, a natural stone. The glazing of the brick surface is also a very popular kind of decoration.

As a result, the surface of the brick acquires a very elegant and beautiful appearance and a pleasant shine.

clinker brick

It represents the same ceramics in a more modern version. It is made from a special grade of clay. It is fired at a very high temperature. The output is very strong and durable material.

Clinker brick is used in places where there is a constant powerful load, for example, in window and doorways. With such a brick it is possible to pave the courtyard, the path, and lay the base of the house.

This type of brick is very dense and has practically no pores, that is, it does not absorb moisture. This at times increases the frost resistance of clinker bricks.

The area, lined with clinker brick, will serve decades without cracks and chips, preserving its original appearance. However, the high density of the material has a significant drawback - high thermal conductivity.

Since clinker brick is most often used for finishing facades, the choice of colors and shades is huge. In addition, this material does not have any strict standard dimensions. For example, on sale there is a so-called "long brick" - 52.8 centimeters in length. The width is 10.8, the thickness is 3.7 centimeters.

hyperpressed brick

Such a brick is made without roasting. As an alternative to high temperature, a powerful pressure is applied to which preformed preforms are subjected. Sand and clay are not used in the production of hyperpressed bricks, its constituents are limestone, cement-based additives and dyes of all kinds.

The technology of production makes it possible to make the front side of the brick "torn", in the form of a beautiful cleavage, imitating the surface of natural stone. This feature of the material is widely used by designers and allows you to create a very beautiful and original surface. It should also be noted that with hyper-pressed bricks it is very easy to work, and at the same time it does not lose its properties.

Hyper-pressed brick is durable, resistant to frost, has a shape close to ideal, without any irregularities and deviations from the right angle. The only significant drawback is the high thermal conductivity, which, however, is easily eliminated by installing a heat insulator.

facing brick: solid and hollow

The brick intended for facing works can be as solid - without any voids, having a high density and a large weight, and hollow, that is, containing the cavities inside.

From monolithic, full-bricks it turns out to be very strong, but at the same time, "cold" lining. The hollow brick, though more fragile, keeps the heat well and, moreover, has a low weight.

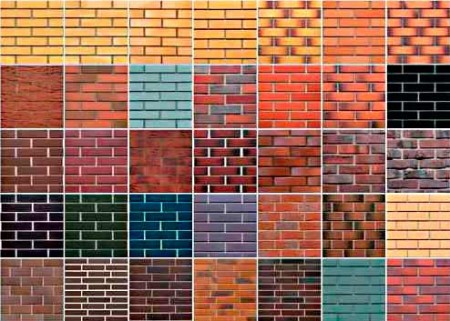

Criteria for choosing the color of the facing brick

Choosing the types and colors of bricks for the facade of the house, designers primarily pay attention to the color of windows, roofs, doors and other elements. In addition, the choice of color largely depends on the shape of the building and its dimensions. If the facade has a small area, then the human eye sees quite a few tones. Many of them are "blurred", for example, a yellow brick will look paler and duller than it actually is.

Therefore, when decorating small facades, choose a brick of bright, juicy, saturated colors, which immediately attract attention, for example, red brick.

If the developer wants to fully reveal a not very bright or dark tone, it is necessary to trim a sufficiently large area with such a brick. For example, to impose on them the whole wall. But in this case it is necessary to take into account the fact that the person's eye often perceives a dark tone simply as a continuous, inexpressive black.

Also, do not forget about the correct combination of colors, because in the aggregate they look completely different than individually. For example, if the colors have approximately the same brightness, then they can, as it were, change in tones. This is especially noticeable when the masonry element of the same color is framed by another.

Lego brick

The name speaks for itself. And it's true - the prototype of this type of brick is really the children's designer "Lego" - it was he who inspired the engineers-technologists to create a unique building material of his kind, which is called: "Lego-brick." In form, it really resembles greatly enlarged details of the child's designer.

advantages of lego brick

One of the main advantages of this building material is its appearance. Technologists did not have to reinvent the wheel, they, if I may say so, simply increased the details of the children's designer, thus creating a real "designer for adults". All bricks have strict standard sizes and special grooves, thanks to which laying the brick is many times faster and easier than usual. The brick is partially hollow, therefore, has a light weight. Holes in the brick can be used for laying communications, for example, electrical wiring.

Lego brick is produced by hyper-injection. The finished product is very durable and does not require additional high-temperature treatment. This method of manufacturing is economically very profitable, since it significantly reduces the cost price. In the process of producing lego bricks, various kinds of fillers are used, after screening, and so on. Adding marble, dolomite, limestone crumbs allows you to get products that differ in appearance and structure. Using various kinds of dyes allows you to get products of unusual beautiful tones and hues.

Since the lego brick is very strong, it is used to build the capital walls. And due to the peculiarities of the brick construction, the walls are perfectly even.

Another advantage of this building material lies in the technique of its laying. Instead of cement mortar a special glue mixture is used. Its consumption is very small - a standard bag is enough to lay several hundred bricks, which is very profitable.

For laying a brick on your own, you do not need special building skills. The main thing is to carefully and exactly lay the bottom row, after which the process will go by itself - you just need to lay the bricks in the grooves. Since the solution does not need to be diluted, strength and time are saved, besides it is much easier and more convenient to work with glue, and the appearance of the finished structure turns out to be more accurate and aesthetic.

So, let's summarize and briefly list the advantages of a brick:

• Light weight with high strength.

• Easy operation.

• Attractive appearance, wide range of colors.

• Ideally flat surface of the finished structure.

• Low consumption of glue mixture.

• High speed construction of building structures.

However, despite the fact that professional builders appreciate the advantages and technical characteristics of the lego brick - resistance to negative temperatures, low thermal conductivity, resistance to moisture, ideal materials, unfortunately, no. The main drawback of the brick is at the moment - small volumes of its production. Consequently, the speed and volume of construction work directly depend on how well the production of the brick is organized in a particular region.

Lime brick

Silicate bricks are made of quartz sand and air lime. In this case, sand is 90%, and 10% - lime and special additives, which affect the color and strength of bricks.

White silicate brick is produced by semi-dry pressing. Thanks to this method it is possible to obtain a high-quality product having the necessary density. A full-bodied silicate brick weighs approximately 4.2-4.5 kg on average. There is also a one and a half hollow silicate brick, inside which there are several air cavities. This product weighs less - about 3.7 kg.

In the process of construction, silicate bricks of different weight and dimensions are used:

• 250х120х65 - single.

• 250х120х88 - one and a half.

• 250х120х138 - double.

silicate brick: advantages

Laying sand-lime bricks practically does not differ from ordinary ordinary ceramic masonry, except that you need to work more carefully, so as not to soil the solution with the front side.

Silicate bricks are very durable, buildings built or lined with silicate bricks are earthquake-proof and durable.

The high density of silica brick provides a good level of sound insulation, which is very important for living quarters.

Silicate bricks are cheaper than ceramic bricks by about 20%, which saves a lot of money.

Thanks to a wide range of colors, you can realize any design project and build an original building that meets the needs and tastes of the owner.

where silicate brick is used

Most often this building material is used for erecting bearing walls and partitions in multi-storey buildings. The walls, built of silicate bricks, are durable and beautiful.

It is not recommended to build from silicate brick foundations, wells, stoves and chimneys. Also, the use of silicate bricks in places with excessive moisture is contraindicated.

Decorative brick

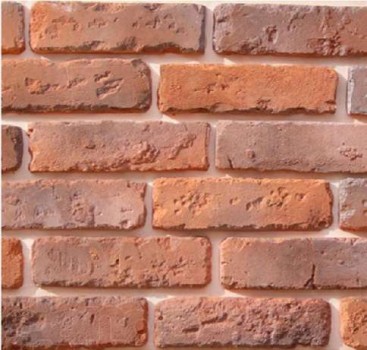

More and more often there are interior design projects, in which the interior spaces are decorated with brick. This fashion came to us from across the ocean. Its popularity began to pick up brick finishing in the middle of the last century.

If a residential building is built of bricks, then in this case everything is extremely simple - leave the walls as is. But when it comes to an apartment with concrete walls or a house made of wood, the room can be finished with an artificial decorative brick.

where decorative brick is used

This type of finishing material is widely used for both exterior and interior decoration. It is most often used for finishing facades, fences, socles and columns, framing arches, etc. Fireplaces decorated with decorative brick look very beautiful.

Since the decorative brick is resistant to moisture and does not show mold, it can be used in rooms with high humidity - in swimming pools, bathhouses, cellars, etc.

advantages and disadvantages of decorative bricks

• A democratic price compared to natural materials.

• Decorative brick does not burn.

• Light weight.

• Environmentally friendly.

• Wide range of colors.

As for the shortcomings, then, for the most part, they lie on the conscience of the manufacturer. To such it is possible to carry:

• Bricks of different shades from different packages.

• Use in the manufacture of dyes of poor quality.

• Various surface defects if the product was cleaned using abrasive materials.