An affordable and cheap option for the appearance in a private house of a heating boiler can be called the device of a pyrolysis boiler, manufactured and installed with its own hand. A thorough study of the layout features, a couple of spent gas cylinders and in a small cozy boiler room the heating boiler puffs. How to realize the centuries-old dream of millions of people who freeze from the cold?

Content

What is a pyrolysis boiler?

Among the variety of heating boilers, solid-fuel boilers are in great demand. Pyrolysis boiler is a kind of solid fuel aggregates, the main fuel of which are wood waste, chips and fuel briquettes.

The principle of the boiler is based on the principle of dry distillation of fuel in the exothermic process. Without going into details and details of the gas-generating process, we add that the boilers of pyrolysis combustion have a high efficiency, reaching 95%.

With high-quality fuel, such efficiency is achievable at the level of the pellet boiler coefficient. Pyrolysis boilers can be called a find for private houses and cottages providing such advantages of living:

• low consumption of cheap fuel

• a long period of burning time during fuel loading

• ecological and quality combustion of fuel

• Low ash content of waste

• high efficiency.

Naturally, the efficiency of the operation of the boilers depends on the connection scheme used and the principle of operation of the pyrolysis boiler.

design of a long-burning boiler: layout features

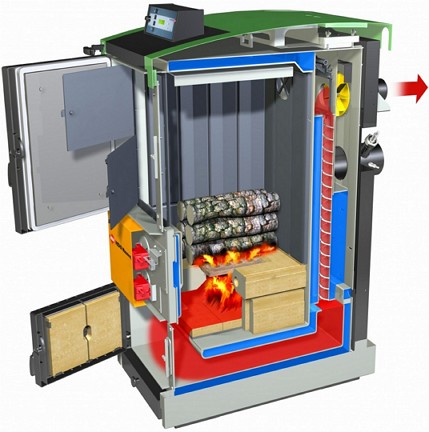

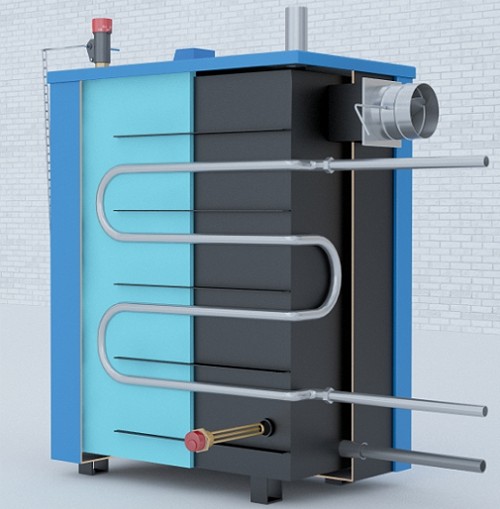

Structurally the boiler consists of the following elements:

• housings made of steel sheets

• a combustion chamber equipped with a cleaning door and an air window

• heat exchanger with water circuit

• Thermal insulation gasket and smoke eliminator

• Automation of control with indication of control.

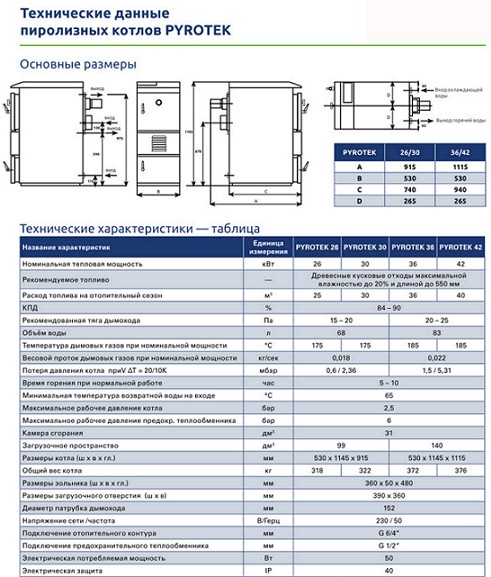

Technical characteristics of pyrolysis boilers

The main technical characteristics of the boilers are:

• heat output and efficiency

• dimensions and volume of the furnace

• type of chimney draft

• the prescribed type of fuel.

Therefore, when selecting a boiler, it is necessary to pay special attention to these parameters. In addition, considering the complexity of the heating unit, it is recommended to study the layout features.

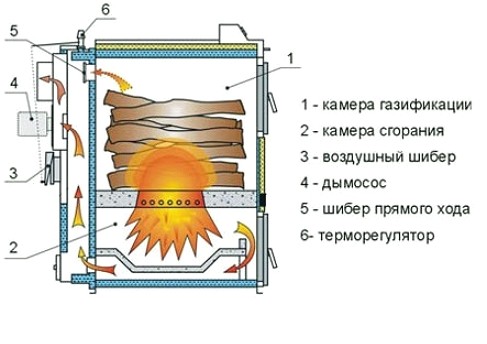

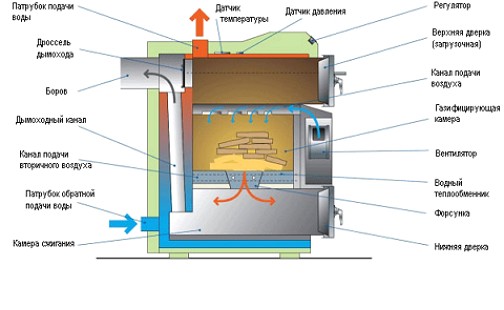

A feature of the pyrolysis boiler layout is the presence of two combustion chambers in the design (for comparison: solid fuel units have one combustion chamber). In addition, to create pyrolysis boilers with a cooling circuit, a cooling coil must be installed.

combustion chamber - location and route of fuel

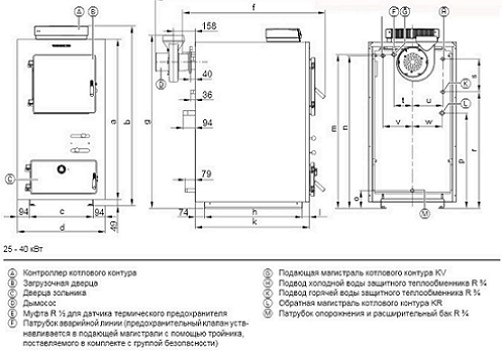

The location of the combustion chambers depends on the design of the air supply: forced feed or natural draft.

According to the forced ventilation option, the gasification chamber is located at the bottom, and the combustion and afterburning chambers are on top. The air mass follows the fuel route from top to bottom.

With natural draft, the combustion chambers are located in the boiler body one above one, with the upper gasification chamber. Combustion chambers are made of heat-resistant alloy steel with a thickness of 5 mm. Air mass passes along the fuel route from below - upwards.

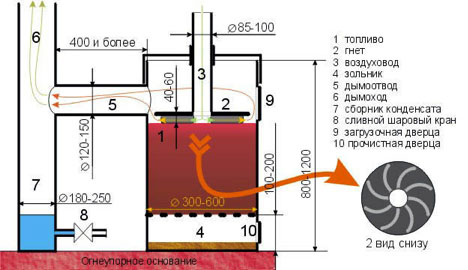

Exaggerated pyrolysis boiler is a famous stove-burzhuyk. Therefore, an important stage is the organization of a method of supplying combustion-supporting air.

organization of air supply method

The method of supplying air to the chambers of the pyrolysis boiler of prolonged combustion is carried out by forced feeding and by the natural draft of the chimney.

Forced air flow can be implemented in such ways:

• fan settings in the discharge mode

• Installation of a smoke exhaust at the outlet of the chamber.

Let's say that creating a forced air supply method will require certain knowledge and skills.

The principle of the boiler is clearly shown in this video.

Installation of pyrolysis boilers from the manufacturer

The main producers of pyrolysis boilers are:

• Atmos

• Bosch

• Buderus

• Viadrus

• Verner.

The process of installing pyrolysis boilers from the manufacturer is terribly expensive, as, indeed, the cost of the boiler itself. But the cold-hammered hands of home Masters are impatient to build an oven with their own hands.

Water bubafony with accelerator on sawdust

materials for manufacturing

The home-made pyrolysis boiler "bubafonya" is a unique offer for the century, like the iPhone, and an accessible invention of folk craftsmen. To create the furnace, you need a gas cylinder with a capacity of 50 liters of propane-butane, a steel sheet designed to cut 2 circles corresponding to the diameter of the gas cylinder.

Metal strips up to 4 mm in thickness and 40 mm in width for blades and reinforcing bars of 14 mm for a grate located above the combustion chamber will also be required.

operating principle

The principle of the boiler, let's call it so - "Bub iPhone", is genius simple. The blades located on the lower "pancake" of the pipe are the generator of the vortex flows of air entering the pipe. The obstruction along the route of the air masses prevents the appearance of fire under the pipe.

Fuel (in most cases it is dry sawdust) is only smoldering under the resistance of the piston, receiving an influx of air masses from the pipe. The water and gas-vapor vapors evaporated during the smoldering process condense in the welded vertical pipe of the boiler.

boiler arrangement

The boiler arrangement consists of the stages:

• manufacturing of firebox

• manufacture of the lid and clamping wheel

• manufacturing chimney and door.

The gas cylinder is cut using the bulgaria on the upper part from the beginning of rounding. In the future, the top part can be used as a cover. To do this, the cut is ground to create a sealed connection. Reconciliation we cut out a hole for installation of a chimney pipe (piston). The gap should be 2-3 mm. We weld the lid on the diameter with a steel strip. If it is intended to produce a furnace with cooling (water jacket), an additional external cylinder will be required to create a pyrolysis boiler with a water circuit.

For these purposes, you can use a pipe of impressive diameter with thick walls.

It should be remembered that the difference in pipe diameters creates a two-stage thrust, and the straight angle of the chimney of the pipe lowers the rate of removal of the gas-air mixture. Therefore, the lateral outlet of the pipe can reach 0.15 m, and the vertical one - 0.20 m. Lowering the pressure of the mixture supports the pyrolysis process for 10 hours.

Then, using a welding machine made of reinforcement, we make a lattice that will ensure the decomposition of the decayed fuel into the bottom of the combustion chamber. To clean the ash chamber at the bottom of the cylinder, it is necessary to provide a door with a dense porch.

How to make a pyrolysis boiler in one's own hand is presented here.