Screw, or spiral staircases leading to the second floor or attic, occupy much less space than the marching ones and look very elegant and aesthetic. Screw staircases look good in any interior: both modern and classic (old), especially since at the present time, steps for stairs can be made of any material suitable for your interior. Such staircases can be installed in rooms of small areas, and are known under the names: rotary, circular or radial staircase. Screw staircases in a private house can be done independently, this will require drawings and the correct calculation of the necessary materials.

Content

Because of its dimensions, most of all spiral (screw) ladders are suitable for rooms with low ceilings and a small area. Such constructions visually "lift" the ceiling and create the illusion of the remaining free space, because of the "transparency" and elegance of the forms. In addition, spiral staircases are very compact, which allows you to use a minimum of free space, in contrast to the marching constructs.

The second and important advantage is the price of such designs. The prime cost of the most spiral staircase and the works on its installation is much lower than that of the marching ones, although this often looks better than its main competitor. Design ideas for the arrangement of spiral staircases are distinguished by a wide variety of forms and decorations, thus enabling to realize any imagination and to give the interior of the room its original style and individuality.

General design of spiral staircase

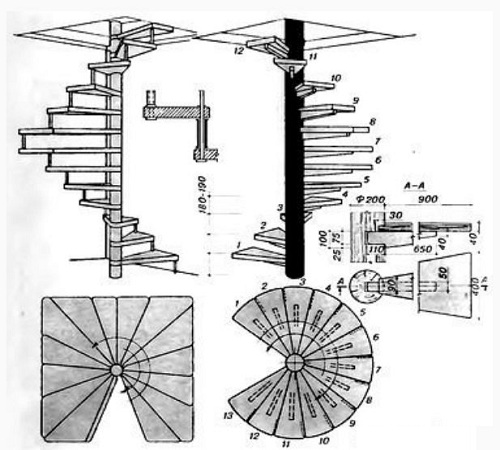

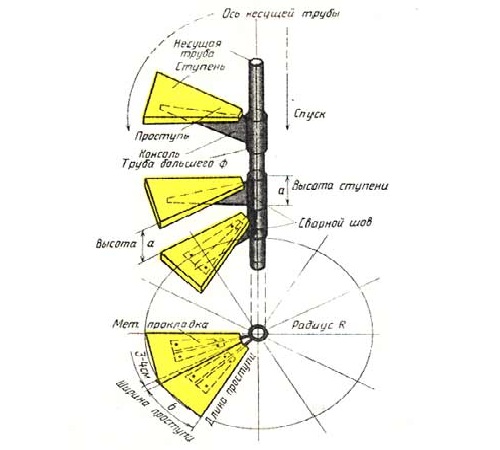

A spiral staircase is a rotary structure. It consists of running steps diverging radially. Also in the design of the stairs are the usual components: rails and supporting elements. Screw staircases can be classified by the type of fastening steps. Since the steps in such a construction are fixed radially, then if you consider a horizontal slice, it will be either polygonal or round.

There is one nuance here: a polygonal shape is more suitable if the staircase is installed next to the wall, this will allow you to save space as much as possible. It is more practical to place a circular structure at a distance from the walls, or in the center of the rooms.

The design of the spiral staircase can be:

- With the fastening of steps in the support column.

- With the location of the steps on the support post.

- With the support of the steps on the bowstring, fencing, Kosower.

- With the support of the steps on the adjacent wall and support post.

Very often the steps of the spiral staircase are fixed on the bolts. In this design, the railings are bearing and create additional rigidity to the entire ladder. Also as supports are spiral-shaped obliques and bowstrings. The angle of rotation of the spiral staircase is 270-360 0.

Here we mean a ladder installed in a standard house. It should be noted that spiral staircases, the dimensions of which are minimal, do not allow a complete turn of the spiral structure, because due to the limited height, the beginning of the movement along the ladder in projection coincides with its end. So it turns out that in rooms with low ceilings it is not always possible to withstand the necessary normative indicators: at least two meters should be between the lower level of the protruding part of the upper platform and the plane of the third from the bottom of the offense.

At the spiral staircase, the steps are always wedge shaped. In this case, for convenience, you should leave a narrow inner side of 100 mm, and the outer wide - from 400 mm. As if the owners did not want to save space, but the most convenient to operate the ladder with a span of more than one meter. Consequently, the entire structure, taking into account the dimensions of the central pillar, should be from 2.2 m in diameter.

Nevertheless, it should be noted that the independent calculation of the spiral staircase is rather complicated and laborious and is best handled by specialists. Producers offer standard designs of spiral staircases, ready-made components, make and install stairs to order according to standard and individual drawings. At the same time, the cheapest and simplest version is the spiral staircase, where the steps are fixed to the helical handrails (on the balusters) and the central pillar-support.

In general, the spiral staircases are executed in such a way that the movement along them occurs counter-clockwise. This is due to the fact that most people begin the ascent and descent from the right foot. However, there is no fundamental difference, and you can mount a descent along the spiral staircase in any direction.

What to make a spiral staircase

The spiral staircase can be made of all available materials: wood, metal, plastic, ceramics and even concrete. The central pillar is basically a metal with a wall thickness of 4 mm and a diameter of 50 mm. If wooden spiral staircases are installed, they are sometimes provided with a wooden column pillar. By the way, when manufacturing spiral staircases from different materials, the central pillars can be solid and made of natural stone, brick, concrete.

For railing take metal or glued wood of various types of wood. And, naturally, all materials can be perfectly combined with each other. For steps of metal stairs take a thick sheet steel, for handrails - openwork weaving of forged rods. Very beautiful look the degree of the spiral staircase, made of thick tempered glass or high-quality colored plastic.

How to make a spiral staircase as comfortable as possible

Whichever the staircase is, you should always approach the issue of convenience and maximum comfort during operation, as well as the safety of movement around the structure. To ensure that the operating time is long with maximum comfort, the following requirements should be adhered to:

- The installation of the spiral staircase rack is only possible in the place where the floor has been made of solid floors. The area on which the ladder will be mounted must withstand the weight of the structure itself and people moving along it. Fastening of the ladder rack must be rigid. It is best to install the support rod on a separate concrete pad (pillow). Anchor bolts are required for fastening.

- To find the location of the central rod at the bottom, from the chosen point on the ceiling, lower the plumb and lower the point of fixing the central rod on the floor.

- The optimum height of the passage is 2 meters. This size should allow you to move freely along the stairs, without touching the upper elements with your head. Naturally, if the growth of someone from the tenants of the house about two meters, then the height of the passage should be slightly increased (by about 10 cm).

- Steps for a spiral staircase are best done without a riser. This will allow you to maximally comfortably lean your feet on the entire step, even in the narrowest places (directly next to the rack itself). In this case, the width of the middle of the step is from 25 cm. In each complete turn there must be more than 12 steps.

- The steps of the spiral staircase are attached to the central shaft by a narrow side. The height of the sleeve (sleeve) is the same as the height of the riser minus the washer, which is installed between the missteps and bushings. Intermediate washer is necessary for the protection of structures from deformation.

- To further strengthen the ladder design, it is necessary to (overlap) the overlap of the steps (with one approaching another several centimeters). The special strength and safety of the construction is achieved by fastening the steps with brackets (in their wide part), which are installed between adjacent steps.

Exact calculation of the design of the spiral staircase

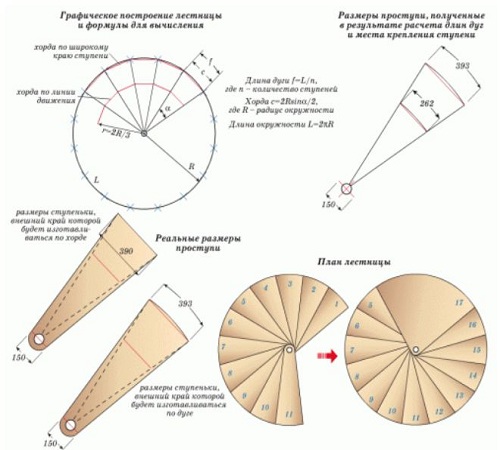

The height of the ladder directly depends on the height of the room. For accurate measurements it is necessary to use a tape measure and a plumb line. The width of most spiral staircases is about a meter. To understand how to properly perform the entire construction, we present the calculation of the spiral staircase according to the standard: height - 3 m, width - 0.9 m. The central pillar - diameter 0.25 m.

- The total diameter of the spiral staircase: two widths of steps add up with the diameter of the rack:

0,25 + 2х0,9 = 2.05 (m). - To calculate the trajectory of motion, a circle with the resulting diameter (2.05 m) is applied to the sheet of millimeter paper, and then another one is added to it, which will also indicate the trajectory of the movement along the ladder. The radius of the inscribed circle is obtained by dividing in half the sum of the width of the ladder and the diameter of the support post:

(0.9 + 0.25) / 2 = 0.58 (m). - In order to correctly calculate the number of stages in one turn, the average value of the width of the steps (0.2 m) is divided by the circumference (2RR) of the trajectory:

2х3,14х0,58 / 0,2 = 18,06 (m). Thus, we obtain 18 steps per one turn of the ladder. - To properly calculate the height of the turn, the circle of the ladder must be divided into 18 parts. In this case, between the first and last step in the coil should be not less than 1.85 m + margin of 0.1 m. The thickness of the steps is 0.05 m.

0.05 + 0.1 + 1.85 = 2 (m). - The height of each stage is calculated from the height of one turn and the total number of steps:

2/18 = 0.11 (m). - To obtain the total number of steps, it is necessary to divide the height of the ladder (3 m) by the height of one step:

3 / 0.11 = 27.3 (m). From which it follows that the required number of steps is 27 pieces. - The final height of each stage must be obtained by dividing the height of the ladder by the total number of steps:

3/27 = 0.11 (m). Here we obtained a similar result (see clause 5), but sometimes it may differ slightly and be corrected.

How to assemble a ladder yourself

For the correct assembly and installation of the spiral staircase, you will need to execute its drawing and to determine the exact order of the installation of individual elements. Any spiral staircase, the drawing of which has already been completed, is installed in the following sequence:

- Support stand.

- Treads and intermediate sleeves.

- The distribution of the steps along the circumference (the landmark is the correct setting of the first and last steps).

- Support brackets.

- Fastening the last stage (to the ceiling).

- Balusters and handrails.

There is a spiral staircase with their own hands in the following order:

- At the selected location, for the subsequent installation of the support post, a thrust flange is installed, which is the supporting lower assembly.

- The first stage is installed on the floor. It inserts the central rod (stand), is wound into the flange and fixed. Verticality of the central core is checked by the building level.

- On the central core (casing) should be "strung" steps and bushings. This work is carried out in a certain order (according to the drawing). All elements are fixed. At the same time, it is always necessary to check with a pre-drawn drawing or instruction (in the case of a ready-made prefabricated structure).

- The staircase, or the upper stage of the spiral staircase, is attached to the side walls of the opening at the level of the second floor.

- The support rod is fixed in the upper part of the structure.

- Completing the assembly of the spiral staircase by installing fences and handrails.

Attention! The ways of mounting the spiral staircases can vary depending on the design and type of materials. In each case, you must strictly adhere to the drawings and installation instructions.

How beautifully to finish

The most pleasant work is finishing. And here the flight of fantasy is unlimited. The only condition is one - the finish must match the style of the stairs and fit well into the overall interior of the room.

Depending on the material of manufacture, for example, the steps can be tiled. On the balusters and railings to install a beautiful LED lighting, you can highlight every step - ideas are an unimaginable number!

In conclusion, it should be noted that when choosing a place for a spiral staircase and installing it, you should strictly follow the safety rules and recommendations for the assembly itself. Neglect of the basic requirements for the size and stability of the entire structure can be damaged during operation. The highest degree of reliability is provided during the manufacture and installation by specialists.