It is known that the production of tiles for paving is now spun off into an almost independent industry with an abundant number of enterprises. A solid nomenclature of produced figured elements and forms for paving makes it clear that the creative potential of handicraftsmen is strong. To create garden paths in the course are things reminiscent of the configuration of the mold for manufacturing - polyethylene bowls, welded patterned or undulating ribbon loops on the handles.

Content

The slogan: "The form defines consciousness" has long been outdated and the very form for manufacturing is going through not the best time. How original the pattern given out by the homemade form is unambiguously difficult to say. I want to believe that October 17th will revolutionize the design of garden paths.

New design of garden paths

Autumn is the best time to update the garden design, make or restore paths and borders. Concrete and stone paths are durable and durable due to the best qualities of the material, therefore they are built for pedestrian traffic and access roads.

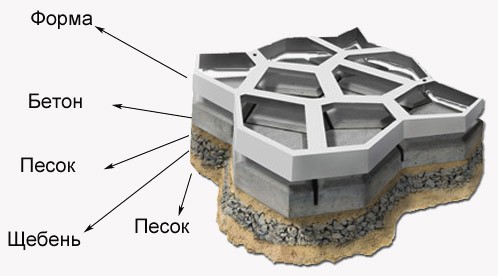

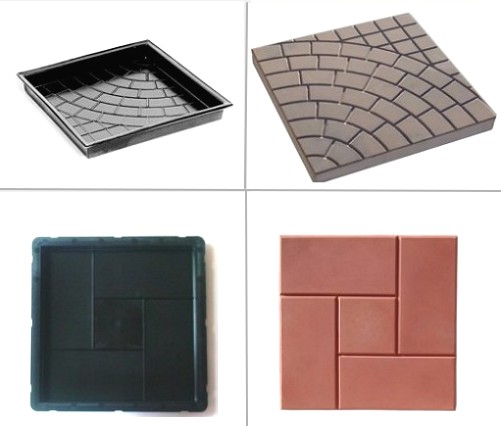

Proposed by manufacturers a great variety of shapes and sizes of garden paths implies certain ways of their construction, using popular and proven building materials: concrete, cement and crushed stone. Traditionally, for the design of garden paths use the classical form of tile geometry - rectangular, hexagonal or triangular. Of course, the classical shape of the tile fits well into the style solution of the suburban area.

Probably, therefore, ready-made reusable forms for making tracks or paving slabs that are available to buy, repeat the stylistics of plate material.

How to create garden paths with low costs with your own hands? The answer will provide information on the basic technology of molding.

Basic molding technology

The basic technology of creating and manufacturing garden paths involves the following activities:

- layout and layout of the placement area

- choice of shape for the garden path

- preparation of a molding solution

- processing of the inside of the mold by machine oil

- pouring the finished solution into a fixed form

- complete cycle of drying and setting

- removal of form and filling of seams with sand or rubble

- additional decoration of the track fragment.

Basic technology is successfully used in creating tracks, and a form for paving slabs for slab material.

we select the form for manufacturing of paths and plates

For the production of fragments of garden paths and slabs in an industrial way, special tools and equipment are used - vibration table with electric motor with amplitude selection, vibropress, hot molds and lubrication.

Ready-made forms of solid polypropylene or ABS-plastic δ = 2-3 mm (primary) have an original geometry and glossy surface and have a specific use cycle of 400-500.

The sizes of the forms are standard - 50x50x5 cm and 60x60x6 cm, the height of the created plate is up to 20 mm, the weight of the mold is from 1-1,5 kg, which fit well on all sides during laying. For convenience, the molds can be equipped with handles.

A special feature of the ready-made tile forms is a slight angle R of the base, ensuring small dimensions of the joints.

These factors allow you to create tracks, pave sidewalks and establish curbs from the form without specific training. The main thing is to choose the composition of the molding mixture correctly.

Helpful Tips

Industrial technology for the production of paving slabs and paving elements requires a certain composition of concrete.

Let's show that the composition of concrete is as follows:

- mineral binder - commodity portland cement M300, M400, M500

- inert aggregate - crushed granite fraction 0.05-0.10 mm

- clean, medium-sized river sand

- plasticizers and dyes

- water.

Naturally, it is recommended to adhere to such a composition of concrete when selecting a molding composition for independent creation of tracks and slabs.

For example, to create a gray tile using molds, it is necessary to use the composition of the mixture,% by weight:

- Portland cement M400, M500 - 23%

- Crushed granite 0,10-0,20 mm - 57%

- Clean river sand - 20%

- Water - up to 30%.

Technologically, it is assumed that the concrete solution is prepared in a concrete mixer with a gate with warm water and a certain mixing time (15 min). It is important to remember that initially dry ingredients are mixed, followed by the addition and injection of a plasticizer.

Create a simple track of gray concrete will help this video.

In order for the concrete composition to acquire a bright and juicy color, we introduce a pigment dye or decorate the outer layer with colored mosaic.

how to make a garden path from round slabs with mosaic

Originality and originality of plates of the round form starts to displace traditional rectangular plates. Unfortunately, forms for round plates are produced in small quantities. Therefore, for your own performance, you can use a product made of durable round plastic - a shallow pelvis (bowl). Quality stamping of the shape of a container of solid polypropylene will ideally provide the creation of garden slabs with the possibility of introducing a mosaic made of fragments of colored glass and tiles.

Step 1. Prepare a mosaic base for the outer layer of the plate of colored fragments.

Step 2. We treat the inside of the form (pelvis) with engine oil.

Step 3. We will place and compose a mosaic on the surface of the form.

Step 4. We paste the mosaic on a rigid transparent membrane, and place it in a membrane up.

Step 5. Prepare a molding mixture of standard composition.

Step 6. From a large-mesh net, cut out a circle or square for the reinforcing layer.

Step 7. Fill the mold with a ready-formed molding compound.

Step 8. Distribute and we will mix the mixture.

Step 9. On top of the molding mixture we place the reinforcing mesh.

Step 10. Flip the shape with the contents and remove the membrane membrane. The mosaic must remain on the stove.

curb making

The technology of creating a paving curb using molds and pouring a ready-made concrete slurry is identical to the technology for making slabs.

Helpful Tips

Let's tell, that time of preparation of a concrete mix before the moment of manufacturing by a manual way of a border on should exceed 70% from the beginning of setting of cement.

Video will tell you how to create a sidewalk curb from the shape.

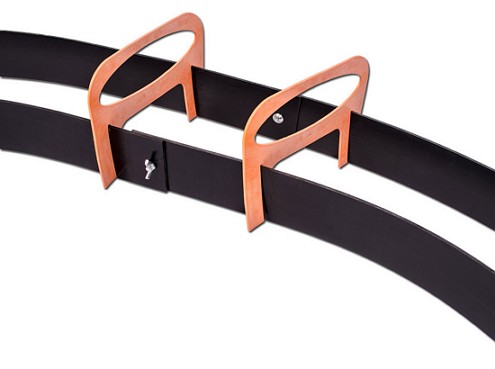

Flexible plastic curb

Flexible plastic curb, manufactured by European technology, is still a wonder in our suburban areas. A feature of this curb is the ability to locate along curvilinear lines, separating the soil from the garden paths.

In addition, this curb is a good barrier to the flow of moisture from the flower bed or lawn. The plastic border is simple for self-assembly and includes a base and special fasteners.

What is a set of flexible borders is shown here.