Water supply of a private house on a level with heating is the basis of comfortable living of owners. Earlier, when there was a question on a laying of any pipes, at once searched for the welder. At present, the laying of metal pipes has remained, basically, in the twentieth century. Now the water pipe is assembled from polypropylene pipes. Such work can produce even an employee - a layman.

Content

Required knowledge and equipment for working with polypropylene pipes

The main equipment is a welding machine and pipe cutter for polypropylene pipes, the equipment depends on the diameter of the pipes to be mounted.

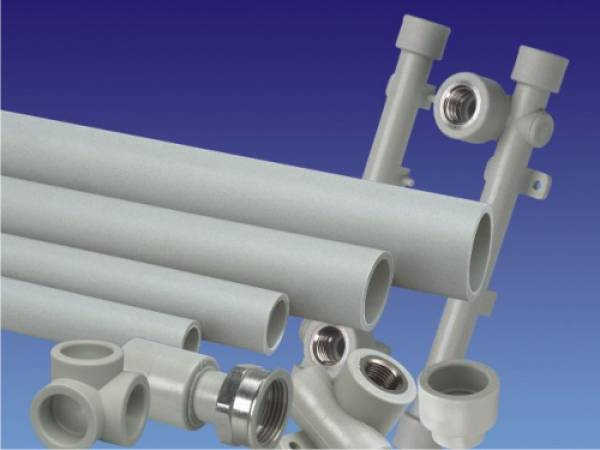

Polypropylene pipes are produced in different versions.

Depending on the operating pressure and temperature of the working fluid, polypropylene pipes are classified as follows:

-PN10 - only for cold water;

-PN16 - for cold and hot water;

-PN20 - for heating and hot water;

-PN25 - only for heating.

Pipes PN20 and PN25 are reinforced with fiberglass or aluminum foil, since a liquid with a temperature above 60 * C moves through these pipes.

At such a high temperature, conventional polypropylene pipes, when expanded, can sag - therefore they are reinforced.

Acquiring pipes and fittings of the required diameter, you should pay attention to the quality of the product, namely:

- The quality pipe and fittings on the cut must have an ideally round shape;

- The thickness of the wall must be the same throughout the diameter;

- there should be no roughness and rush;

-if the pipes are qualitative, then without heating, you can not join the pipe and fitting, since after heating, even high-quality parts are joined with great effort.

Create a project of water supply at home

Before starting work, you need to calculate the number of pipes and parts, and for this you need to make a detailed diagram.

To facilitate the work with the scheme, you need to consult with experienced builders or get knowledge through the Internet, through video clips.

We will tell you about the basic principles of creating a scheme:

-circuit must have the least number of bends and intersections;

- the length of the water pipe must be minimal;

- the connection of the main line can be made in a closed or open way.

If you select a closed method, that is, you must hide all the pipes in the wall.

With this method, it is desirable to conduct a pipeline without joints, since the joints must be accessible for inspection and operation.

Those. closed variant is complicated, exact calculation and work of professionals is required.

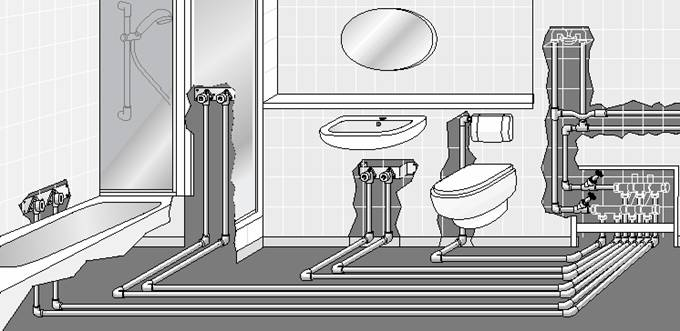

The open wiring is done in the form of a pipe distribution vertically in the corners of the room, and horizontally at the floor level.

Such a system is easy to maintain and install.

Sequential routing of polypropylene pipes

The distribution of water supply can be different.

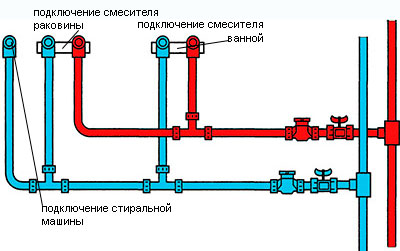

Let's consider a sequential or tee wiring system.

From the riser, on which the inlet locking device is installed, two pipes depart: for cold and hot water, then using tees, they make bends to all points of consumption.

Advantages of this method:

-economy;

-small amount of material;

- Simplicity of installation.

Disadvantages:

- the interdependence of consumer devices, it can only be done by placing additional stop valves on each branch;

- differential pressure with simultaneous operation of several points;

A large-sized tee-node takes up a lot of space.

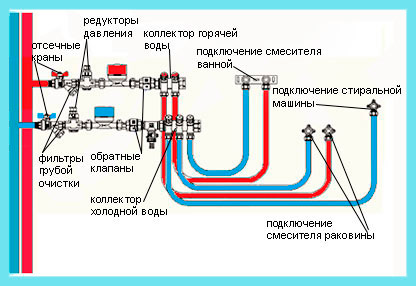

Parallel or manifold wiring of polypropylene pipes

Parallel wiring includes a collector, which has one input and several terminals (depending on the points of water consumption).

Each draw-off has a personal conclusion.

Pluses:

The water is distributed uniformly over all points;

-In case of an accident, you do not need to disconnect the whole system;

- It is possible to install meters and a pressure regulator in each plumbing unit.

Disadvantages:

-There is a large number of pipes;

The cost of the system is more expensive;

-more complex and extensive installation work.

We make installation of polypropylene pipes by our own hands

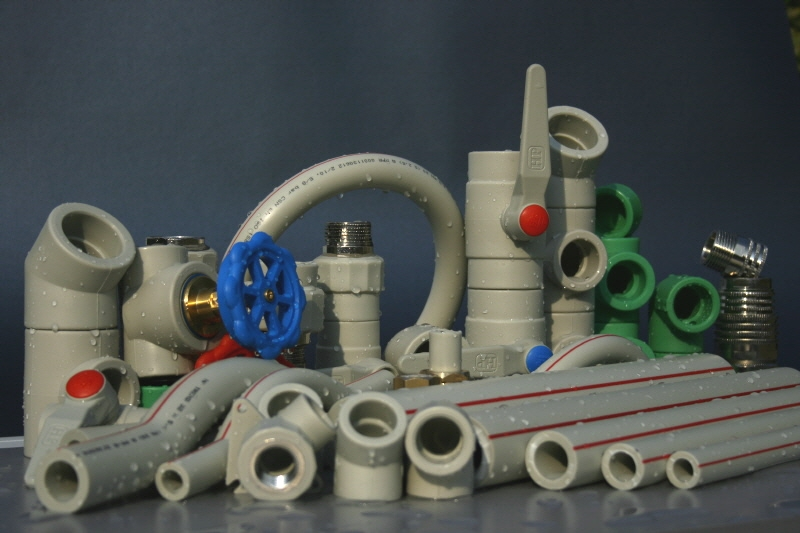

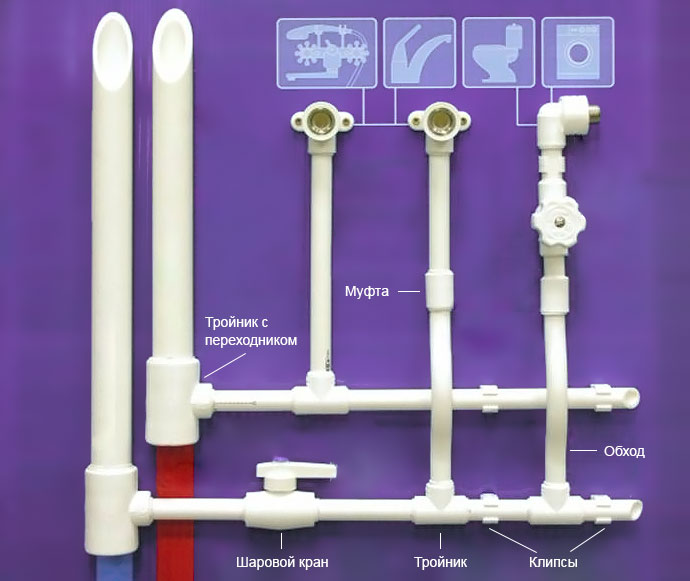

In accordance with the scheme, we purchase the required number of pipes, special couplings (for pipe joints and transition to another diameter), corners (for turns and avoiding obstacles), tees, plugs, crossings, stop valves.

When purchasing, contact the seller-consultant, he will tell you the necessary spare parts.

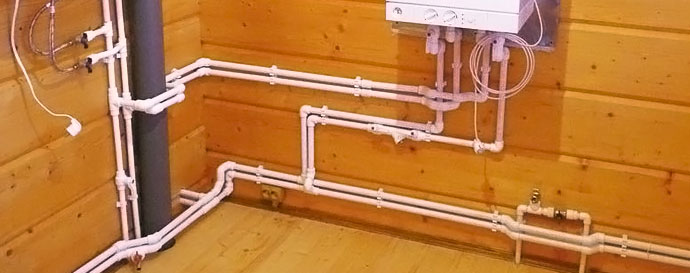

For fastening pipes, on walls, clips are used, they are installed through 1.5-2 meters on straight sections and in each corner joint.

If the pipes are installed one above the other - it is convenient to fasten with double clips.

Stands are fastened with a metal clamp with a rubber gasket.

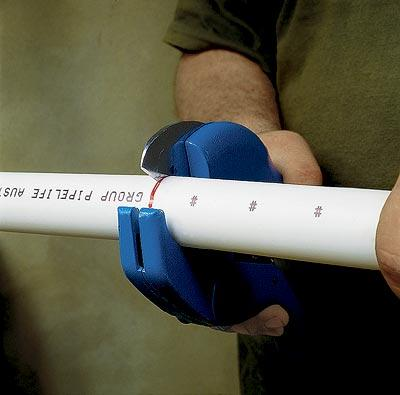

Before the work starts, the pipes of the required length are cut, the pipe section is cleaned and degreased, the nozzle for the soldering iron is selected, it is also degreased.

Install the parts in the device, warm up the device to 260 * C, the lamp goes out on the body - begin to weld.

If there are no skills, train on trimming pipes.

The pipe and fitting are installed in the right place until they stop, after heating the parts they are removed, the work on combining the fitting and the pipe must be fast and accurate, they must be moved to the stop.

You can not do any rotation movements, because the heated parts are plastic, so they need to be fixed until it cools down completely.

After cooling you will get a strong connection, it will last you many years.

Even an inexperienced plumber can do this job.