Wooden objects of everyday life and wooden houses are an amazing man-made skill of mankind. We are fascinated by the pleasant coolness of the interior of the house in the summer and the cozy atmosphere in the winter. And it does not matter from what material the house is built, from a beam or a log. The main thing is to build a house using the technology. We will share useful advice on design and construction.

Content

Designing a house from round logs

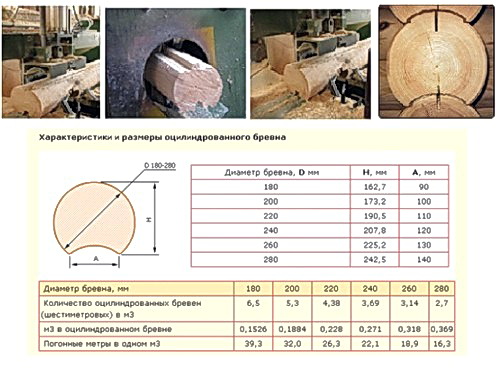

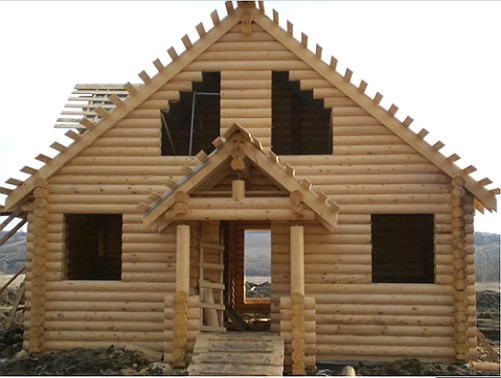

The favorite for the construction of wooden houses is a round log. Developers prefer the product of natural wood for the noble appearance of flat walls and the elegance of the facades.

Therefore, to build a log or a small building out of round logs means to erect a solid and reliable construction. Today, the technology of houses from round logs combines the old techniques of working with wood and new ideas of wooden housing construction.

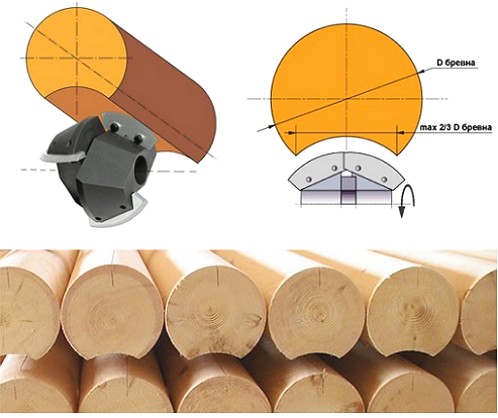

Naturally, the design and calculation of the cost of construction begins with the choice of material logs at home from rounded logs, projects and prices are calculated for any material possibilities. In addition, it is necessary to choose a solid manufacturer of building material, in which the production of rounded logs on lathe-rotary machines does not have any technology violations.

Logs for construction must have a constant section and length calibration and a mechanically cut lengthwise compensating groove. The assembly bowls are cut in place. For reference, the price of a cube of rounded logs depends on the diameter and is 7600-7900 rubles. Therefore, it is first necessary to determine the diameter of the product.

Helpful Tips In practice, the distribution of costs for building a house from logs rounded is as follows:

- design and drawing up of sketches, drawings - 10%

- choice of the construction of the foundation and its creation - 5%

- erection of walls and ceilings from a log - 45%

- engineering equipment and systems -20%

- creation of enclosing structures (doors, windows, roofing) - 15%

- interior finish - 5%.

We will specify that the standard project of a house from round logs is cheaper than a special project.

Technology of building a house from round logs

The technology of construction from logs rounded consists of stages:

- Log Choice

- Foundation construction

- Assembling and erection of walls

- Shrinkage of the assembled structure

- Sealing work and log protection

- External grinding and interior finishing.

The basic technology takes into account examples of construction of houses taking into account the minuses of a round log with a cross section of 220-240 mm of standard length of logs 6,12 m, which are considered to be the best wall material.

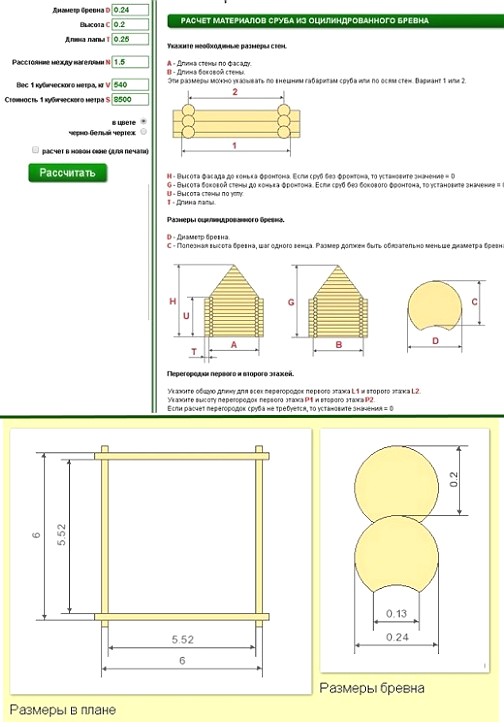

material calculation

To calculate the material for assembling a house from a log, use the free on line calculator. As a result of the calculation of the length of the side walls, the facade and the height of the wall along the corner, the following will be obtained from the initial data: the height of the walls of the main frame and pediments, the number of rims and the total length of logs, the number of nagels, the weight of the log structure (kg), the area and volume of material (m3) .

selection of logs and their transportation

The choice of logs and the cost of rounded cube logs are influenced by:

- appearance and quality of wood

- humidity (naturally-dried wood is more expensive by 50%)

- degree of processing of wood roughing / finishing and the presence of impregnation

- material parameters (length, section, type of rounding or profiling).

According to the developers, round logs are the best more expensive by 15%. By the way, transportation of logs to the construction site is considered important. The numbered logs from the manufacturer before transportation are fixed in motor vehicles. The unloading of logs is carried out to the ground in order of numbering for the convenience of subsequent assembly.

Helpful Tips Construction technology is complex and time-consuming.

Preferably use the services of companies and companies that offer standard equipment technology:

- Free sketch design and building facades

- Assembly and installation of walls of the first and second floors and partitions

- Laying of the flax linen insulation

- Impregnation of the bowls with biosecurity composition ECOSEPT 440

- O-ring gasket between foundation and crown

- Erection of the rafter system from the bar 220x70 mm, step 800 mm.

The finished house set consists of a set of lumber rounded logs and beams, a set of standard fasteners (nagels, expansion joints and intervent insulation).

preparation of the construction site and mapping of the relief

Before the construction of the foundation on the site, the axes are broken and leveled. The general decision on the choice of the foundation is determined by the configuration of the site on the basis of geological calculations based on the initial data of the building spot. Specialists consider the preferred variant of the soil for the construction of a house from logs rocky soils of a monolithic massif with insignificant water saturation. The relief map for planning is made using hydraulic level marks, the connected points should have the same height.

foundation erection

Round logs have an impressive weight, so preference is given to a ribboned shallow foundation with a width of up to 300 mm or columnar with a cross section of 300x300 mm columns located at a distance of up to 2.0 m from each other. A variant of the combined basement is possible - the residential part of the house is placed on the belt, extensions and terraces on the columnar.

Useful tips for calculating and erecting a shallow, shallow foundation, shown here http://svouimirukami.ru/articles/lentochnyj-fundament-kak-pravilno-rasschitat-fundament.html

After the construction of the foundation and its waterproofing, the laying of the lining bar is made according to the working drawing of the scanning of the wall parts.

walling

Before laying the logs of each crown in the longitudinal groove, lay and fasten the cloth of the interventure heater with a width of 200 mm and a thickness of 5 mm. The edges of the jute canvas are folded and straightened in a bowl. Between each other, the crowns are fastened together using a nagel, placed in a staggered manner with a step of 1 m.

Full assembly of walls is shown in the video.

After assembling the frame of the house from the log it is left to shrink the structure for 1 year. The final stage of the construction is polishing and protection of logs with subsequent internal and external finishing.