The issue of thermal insulation of buildings for various purposes in our time sounds very relevant. But if you want to get the maximum heat savings, keep the environment-friendly construction, consumers also want to save their money. That is why it is very often possible to find articles with comparative characteristics of insulating materials, in which the advantages of some and the shortcomings of others are vigorously exalted.

For example, a comparison of expanded polystyrene and expanded polystyrene is made solely from their technical characteristics. As a serious argument, it is also reported that in Western Europe, construction workers prefer polystyrene foam. But at the same time, it is practically never mentioned that the houses built in these countries are initially equipped with a perfect forced ventilation system, which has not yet received a very wide distribution. Let's figure out what exactly the advantages of this or that insulation are and how important they are in housing construction.

Content

- 1 Styrofoam or expanded polystyrene - what are these materials and how fair are the rumors of their fire safety

- 2 Foamed polystyrene materials - thermal insulation characteristics and service life

- 3 Water vapor permeability

- 4 Ecological compatibility

- 5 Styrofoam or expanded polystyrene - which is better

- 6 We choose the material for external insulation of the walls of the apartment house

- 7 We heat the roof and the walls of non-residential premises

- 8 How important is the strength index

Styrofoam or expanded polystyrene - what are these materials and how fair are the rumors of their fire safety

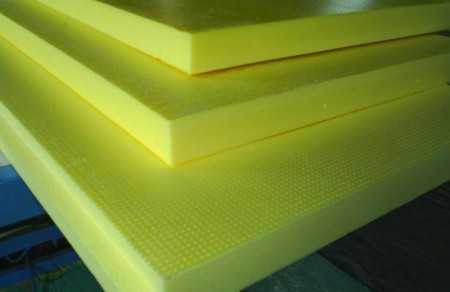

Discussions and arguments about the advantages of these two materials are very active, although both have much in common. As a raw material for their production, polystyrene is used, and the process is based on foaming technology. Some differences in characteristics are explained in the difference between the methods used in their manufacture, the process of manufacturing foam is the processing of polystyrene beads with steam, leading to their foaming. During extrusion, polystyrene pellets are mixed at high pressure and temperature, using a foaming reagent. Quality penoplex has a closed porous uniform structure with cells from 0.1 to 0.2 mm in diameter. To begin with, it should be clarified that, in fact, expanded polystyrene is the same polystyrene, only extruded, and penopolx is its domestic name.

The first of the myths about EPS polystyrene insulators is the statement about their fire safety. Both materials are flammable, in order to impart to them the properties of self-extinguishing they are impregnated with fire retardants, which reduce the combustibility of the material, but at the same time significantly increase the smoke evolution during ignition and increase the toxicity of the smoke. As a positive point, it can be noted that polystyrene treated with flame retardants will not ignite from falling on it a spark or a cigarette butt.

The real characteristic of fire hazard can be made on the basis of their classification: they both belong to the class D (combustible), expanded polystyrene to group G3 is normally flammable, and extruded polystyrene, due to its air saturation, to group G4.

Several conflicting data on the combustibility class can be found for the reason that there are several systems for the classification of flammability of building materials and manufacturers can choose one or the other at their discretion.

Foamed polystyrene materials - thermal insulation characteristics and service life

And the statements that the materials made of expanded polystyrene are the best thermal insulation materials can be considered quite just. Any heat insulator of other origin can only aspire to achieve similar low heat conductivity values (tending to 0.030 (W / m · 0C), but it can not exceed them.If we compare the similar characteristics of foam (0.038) and extruded polystyrene, lower - 0,029 - 0,034 W / m · 0C.

About what the actual service life is characterized by the material can be argued - it all depends on the conditions in which it will be operated. If the construction of the insulated wall provides complete isolation from too high temperatures, the effects of ultraviolet rays, then the service life will tend to 60-80 years. But the open air and the rays of the summer sun will lead them to a fairly rapid destruction.

Water vapor permeability

Continuing the conversation about what is best: extruded polystyrene foam or polystyrene, it should be noted that both materials are not prone to absorbing moisture, the best performance in this case is extruded material - 0.2% vs. 0.4%. The quality characteristics are practically not affected by the numerous freeze-thaw cycles experienced by materials.

The significant difference between foam and expanded polystyrene is the vapor permeability index, for foam it is much higher and is 0.05 mg / (m · h · Pa), which is almost equal to that of natural wood. Penoplex has an index tending to zero, if more accurately 0.013 mg / (m · h · Pa), i.е. it is practically impenetrable for steam.

Choosing as a heater polystyrene derivatives should not expect good sound insulation - both materials have a low noise absorption index. If noise insulation is necessary, it is more rational to use mineral wool materials.

Ecological compatibility

The environmental friendliness of both materials is determined by the content of impurities harmful to humans. Most of these are flame retardants, if they were used in production, then the material should not be considered absolutely safe. You can get information about whether the expanded polystyrene treatment has been processed by the store manager, in which the purchase is made.

The danger is also smoke from the ignited material, albeit in varying degrees, but from the fact that it has been treated with flame retardants and from untreated.

Styrofoam or expanded polystyrene - which is better

Taking into account the characteristics of the materials considered above, it can be said that they are both excellent heat insulators. In addition, the materials differ:

- a small specific gravity,

- simplicity of processing,

- compressive strength,

- ease of installation,

- possibility as an external finish to use plaster,

- their transportation does not cause any problems.

The decisive moment in the choice of a particular material is the field of its application.

We choose the material for external insulation of the walls of the apartment house

In pursuit of the goal of obtaining maximum heat savings at minimum costs, one should be guided by common sense. Since the thermal insulation properties of extruded and ordinary expanded polystyrene differ insignificantly (about 15-20%), the main criteria will be vapor permeability, which determines the comfort of living in the house and the cost of material, the account of which will help to rationally spend money.

Since the foam is the best vapor permeability, and its price is much lower, it is possible, without much doubt, to give preference to it. Savings will also be provided by the refusal to equip the vapor barrier on the internal surfaces of the walls - with good air permeability of all structural elements, it will not be needed.

It is worth noting that in certification documents for facade insulation systems, extruded polystyrene is not registered. However, in the technical documentation of trademarks that the thermal insulator is intended for the insulation of facades, too, is not mentioned.

We heat the roof and the walls of non-residential premises

If the funds permit, then one or the other material can be used with equal efficiency. And both of them will cause problems if necessary to insulate surfaces that are uneven and have curvature.

Expanded polystyrene, ordinary and extruded, is rationally used for the warming of even bases. For example, such as a flat roof. In this case, the main criteria in the choice of material will be low moisture absorption and excellent heat-saving properties.

Both materials will perfectly cope with the insulation of the ceiling, balcony or loggia.

Extruded material is rationally used in structures associated with direct exposure to moisture: for the insulation of foundations, floors of the ground floor, including warm, socle rooms.

If it is planned to use penoplex for thermal insulation of a residential building, then it is necessary to immediately plan the arrangement of high-quality supply and exhaust ventilation, otherwise there is a risk of dampness on the walls, and subsequently - mold and fungi.

How important is the strength index

When comparing the characteristics of materials also pay attention to the index of strength, in the emitted it is much higher. This is important when using the material as a basis for the construction of roads and railways, large sports and industrial facilities, etc. In ordinary housing construction, there will be quite a margin of safety, which is possessed by polystyrene foam. The technical requirements for the floors of buildings indicated that the load per square meter of the area should not exceed 350 - 400 kg. Actually, for compression of foam plastic with a thickness of 100 mm to 90 mm, it will be necessary to attach 1400 kg / sq. M, and for foamed foam - 5100 kg / sq. M.

If we take into account the above, then it is easy to draw such conclusions:

- It is unambiguous that when the basement, the socle and the inversion roof are insulated, it is more rational to use extruded polystyrene foam.

- It should also be used for warming of loggias and balconies, floors, especially on the first floor of the building.

- For insulation of walls, it is possible to use foam foam only if an effective forced ventilation system is used.

- The use of the material is required in structures where there is a risk of severe mechanical stress.

- It is preferable to warm the walls of the apartment house from the outside with ordinary foam.