Floor coverings have an unpleasant property, quite quickly wear out due to high load. This particularly applies to linoleum, low-grade floorboards, ceramic tiles, etc. And in the process of repair, the question arises: what material should be given preference? The question is really important, because the choice in the stores is huge. One of the most popular materials today is laminate flooring, or laminate.

Content

What is laminate

Laminate, this floor covering can imitate anything, because of what, in fact, and enjoys a good demand. Of course, not the least role is played here and the price, as far as not everyone can afford to trim the floor with natural high-quality materials. In this regard, laminate is an excellent solution - and looks beautiful, and the price does not bite too much.

Where do they laminate? Yes everywhere: at home, in offices, cinemas, museums, car dealerships, saunas, warehouses, etc., etc.

When choosing a floor covering, it may seem that, for example, piece parquet or cork flooring is a better solution. Yes, it looks beautiful, but it does not fit everywhere and not always. Do not just focus on the appearance, you need to consider also things like: wear resistance, the complexity of installation, resistance to temperature changes and high humidity. In rooms where the floor is heavily burdened, such as: public premises, offices, shops, etc., a beautiful floor of a piece of parquet or cork will soon require at least repair, and even replacement. A laminate - no. It will last many times longer, provided that it meets the requirements for durability.

According to some characteristics, the laminate is very similar to parquet from natural wood: it is eco-friendly, and it is difficult to distinguish it from the real mass. However, it costs several orders of magnitude less, is not inferior to wood in strength, and even surpasses its service life. Laminate floor is not susceptible to most solvents, it is not flammable, and at high temperatures it does not release toxic substances into the air, the surface of the laminate can be cleaned without fear with an ordinary rag using detergents.

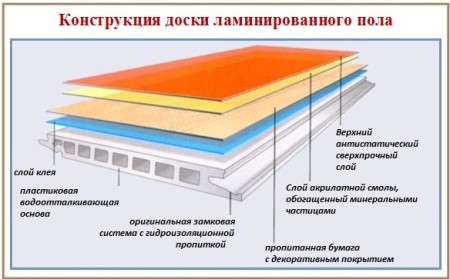

All producers of laminate floor have their own characteristics and production secrets, but any laminate consists of four layers:

• Protective top layer (very strong film made of special resins).

• Decorative layer (most often paper impregnated with resin on the surface of the picture).

• The main layer is a solid wooden tile.

• Lower stabilizer layer - paper impregnated with paraffin or special resin.

The first layer protects the next, decorative layer from chemicals, stains, mechanical damages, etc.

The main layer of the laminate is made of a very high density wood board (HDF) - this allows the material to withstand heavy loads for a long time, and provides high resistance to shocks.

How to choose the right laminate

Do not buy a laminate floor, tempted by a beautiful appearance. First of all, it is worth considering - for which room is it intended? Since the loads for different rooms are very different - for example, in what comparison can there be a load on the floor, say, in a store, with the load on the same floor in the hallway of the apartment? Proceeding from this, manufacturers produce two types of laminate: household and commercial.

laminate classification: stiffness, density, abrasion

In accordance with European standards, the classification of laminate implies the existence of 6 levels of abrasion of the protective and decorative lamella coating. Each category corresponds to the ability to preserve the original appearance when processing its surface with a special abrasive head - the so-called taber test. The greater the number of revolutions withstands the surface without changes, the higher the class of products. The transition between classes is determined by the appearance of obvious signs of damage to the lamella surface during the test.

With regard to the degree of stability of the laminate, it is designated by a special marking: ACx, where x is a certain category, which 6. But this is in Europe. On the territory of Russia and the CIS countries, a slightly different marking is used, consisting of seven figures 21, 22 (discontinued because of too short a lifetime), 23, and 31, 32, 33, 34. The higher the figure, the higher the wear resistance rating, and the stronger the protective coating of the laminate.

Of great importance are also indicators such as rigidity and density of products. They are determined using the so-called Brinell technique. The technology consists in the following: in the lamella, gradually squeeze a ball with a diameter of 1 centimeter. After that, the indicators are taken based on the parameters of the print from the ball. Based on the results obtained, products are assigned to one or another class. For example, if the diameter of the dent is small and shallow, this indicates that the material is hard and sturdy. And vice versa - a deep imprint indicates a low abrasion resistance and stiffness of the material.

So, there are six classes of laminate. The higher the level, the stronger and more durable the material. The strongest is products that have 33 class. There is also the 34th, intended for special use - sports and industrial, but it is not officially registered. Laminate 33-class is the most expensive, it is stewed in offices, shops, gyms, cafes, etc. The products of the 31st and 32nd class are also very high quality and are used in public premises, which are visited by a large number of people every day. For example, the 31st class can be used in a conference room or a meeting room. And the laminated floor of the 32nd class excellently proved itself in small shops, boutiques, reception rooms, classrooms, etc.

Of course, this does not mean that such material should not be used in living quarters. Rather, on the contrary - it will easily transfer all the hardships of "communication" with young children who like to pick up the floor with something sharp, frequent visitor visits, and other hardships. Such a sturdy material is worth using, of course, in the hallway and living room, but for the bedroom and the kitchen you can take the laminate is cheaper - class 23 is quite suitable. By the way, this t class can be used for all apartment premises except for the bathroom.

thickness, water resistance, sound insulation

When choosing a laminate, one should take into account such a criterion as the ratio of the thickness of the lamellae and the area of the room. If the area is large - for example, a storage room, and the laminate is thin, then when walking there may be clinking sounds, and on such a floor you can walk silently only barefoot :).

If, while walking, the laminate floor creaks, this may indicate that the lamellas are defective, with broken geometry, or when installing the floor, a gross error was made. Quality and properly laid laminate will never creak.

Like the vast majority of floor coverings, the laminate floor is categorically "not friendly" with water. The specialists of many manufacturers have long been working hard to eliminate this problem. The results are already today, some types of laminate can be used even in the bathroom.

This is a material with an absorption coefficient of no more than 2%. This requirement must be met by the lamella base - HDF. In order to further increase the water resistance of the laminated floor, the joints of the lamellas are treated with a water repellent impregnation and are glued together with polymer waterproof glue when laying.

To strengthen the sound insulation of the laminated floor and minimize noise when walking, a laminate is laid under the laminate. It can be special porous rubber, natural cork, foamed polystyrene or polyethylene - there are a lot of options. Sometimes the manufacturer produces a material with increased sound insulation, already equipped with a sound-insulating substrate.

Laminate is a light-resistant material, its surface does not fade, in addition, it does not cause allergic reactions. This allows the use of laminate flooring without restrictions in children's rooms, kindergartens and schools, hospitals, etc.

Simulate the depth of the picture of natural wood or stone is very difficult. But modern technologies are developing really fast, thanks to which already many laminate manufacturers can so accurately imitate natural materials, their color, texture and texture (even a varnish coating) that at first glance you will not understand what is really under your feet - laminate or wooden parquet.

When choosing a laminate, do not be lazy to pay attention to the manufacturer's warranty. Its term should be at least 2 years, on average 6. Some manufacturers give 10 or more years of warranty.

Types of laminate for decorative qualities

All the laminate floors produced today are divided according to their decorative qualities into:

• Silky glossy / glossy.

• "A tree under oil paint".

• Country.

• Matt.

• Relief / texture.

• Waxed.

• Natural.

Glossy laminate, as is clear from the name itself, has a brilliant polished surface. Its main drawback is that on the surface there are always prints of bare feet and stains from rags. In addition, it is slippery. This is the most common material.

Natural lamellas are more like wood. All details are thoroughly traced: cracks, knots, pores. A light silky shine may be present.

The waxed laminate is a bit like a tree that has been thoroughly waxed. If there is a light shine - in front of you high-quality material.

Texture lamellas are a fairly good imitation of natural wood. All the roughness and roughness of this tree are drawn very carefully, which allows to achieve the maximum coincidence.

The relief laminate has a symmetrical unevenness, it does not coincide with the pattern. You can mention one more variety, not listed in the list - laminate with chamfer. In the laid out form, it is very similar to wide boards.

On the laminate with matte coating there are no traces of bare feet and rags, in this respect it is more profitable than glossy.

Country laminate is also a relief material.

Each plate is similar to a hand-worked piece of wood. To varieties of relief style refers to the so-called aged laminate. It is masterfully simulated all the chips and protuberances, and the lacquer coating beautifully emphasizes and shows them.

The tree under the oil paint - probably, you do not need to explain anything - the imitation of the painted floor, looks simple and natural.

types of laminate joints

The lamellas can be fixed to each other with a lock or with glue. The second method is very time-consuming and time-consuming. The finished coating is very difficult to repair, since in the case of damage to one or more lamellae, they have to be literally cut from the web.

But this is all in the past - modern manufacturers completely abandoned the glue, and gave full preference to the locking joints - more simple, quick and economical. Such a laminate floor is assembled with the help of special fasteners, which are on each lamella.

types of locks for joints

All the existing types of locks for laminate are divided into two types:

• Lock-locks.

• Click-locks.

The lock-lock or, as it is also called, the lock-latch is a rather simple design. On one side of the lamella there is a spike, on the other - a groove. In the process of packing with a rubber mallet, the thorn is slammed into the groove, that's all.

By the very lamellas to knock with a hammer it is impossible to do this only through a wooden block, and not very much so as not to spoil the part.

Despite the seeming simplicity of the process, the floor assembly is better entrusted to the pros for several reasons: if you do not know all the features of the lock connection, the lamellas are very easy to damage. If suddenly there is a need to transfer the coating to another room or replace the damaged part, you will not be able to do this without the experience.

Click-lock (collapsible joint) is a more advanced development in the production of laminate flooring. Its design is more complex, and does not have the disadvantages of a Lock-lock. A cover with this type of lock can even collect a beginner in this matter. The lamellas simply connect at an angle of 45 degrees. In this case, no need to exert any effort.

Due to the design of the lock, the floor covering is very simple and easy to disassemble and put in a different place. Another important advantage: due to the design of the lock, the floor does not deform with time, and there are no crevices between the lamellas. When laying the laminate it is desirable to work with special sealant joints between the lamellas. This will protect them from moisture drops in the room.

A huge variety of colors, textures and drawings, as well as the ability to choose a material with different types of locks, allow you to choose the material that suits you best and design your house in accordance with your own understanding of the style. Before buying the material, it is highly recommended to consult with specialists in order not to fall for a fake and choose a laminate with the best price / quality ratio.