Finished projects and facilities of a bath from a bar amaze with the dearness. Therefore, the question arises of own construction. How to select materials and stage-by-stage construction?

Content

Calculation of a bath from a bar

The construction of a bathhouse involves the carrying out of design and construction activities.

At the design stage of the bath from the bar, it is necessary to calculate the future structure according to the dimensions of the bath from the bar with the detailing of the rooms.

The construction measures for the erection of the structure assume:

- laying and arrangement of the foundation of the sauna from the bar

- waterproofing straps

- preparation of water supply and draining

- erection of log walls with subsequent insulation

- floor and ceiling with roof assembly

- sheathing and warming of the walls of the steam room

- installation of a furnace, laying of water supply and sewage pipes

- electrical wiring

- interior decoration.

Naturally, the preliminary calculation of the necessary materials for construction and costing will prompt the expediency of the event.

Helpful Tips

According to experts who built more than one bath building, the best option for the layout of rooms are the dimensions of the bathhouse 6x4m. Such dimensions are enough to compactly place the shower and the steam room, as well as a rest room and a small hallway. With the availability of funds, it will be possible to attach a veranda or terrace.

The cost of building a bath

we select the material

To build a bath you need to pick up materials. For example, what bar to choose for a bath with a size of 6x4 m, a total area of 24 sq.m and a terrace area of 4x1.2 m?

For the erection of a log house you will need:

- dry profile, dimensions 45x135mm and 90x135mm

- profile beam, dimensions 100x100mm and 150x150mm

- glued beam, dimensions 150x150mm

This material is the basic kit for the construction of a timber bath. For each case it is recommended to make a calculation that fully provides information in order to know how to build a sauna from a bar.

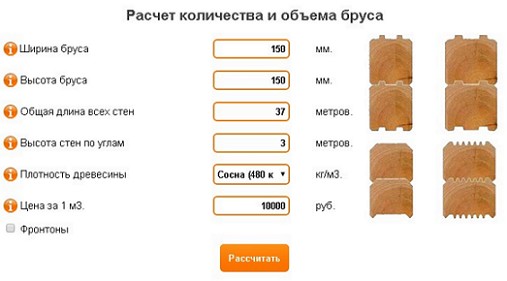

automated settlement

To calculate the construction of a log frame from the beam by yourself, use the online calculator http://stroy-calc.ru/raschet-brusa, with automatic counting of the number of crowns, nagels, intervent insulation and anti-corrosion impregnation.

As a result of the calculation, data will be obtained on the basis of which it is possible to purchase materials for the bath device:

- The volume of timber (the number of sawn timber in cubic meters) and the weight

- Total area of walls for the choice of insulation

- Number of rims and rows in one wall without gable

- Number of roll insulation for all rims (total length of the beam)

- Number of nagels, their diameter

- The amount of protective impregnation from 2 layers

- Wall load on the foundation (for selecting the type of foundation).

Now you can proceed to the construction of the foundation of the bath.

Helpful Tips

Naturally, you can make a calculation manually. But why create a bicycle, if the Internet is already full of comprehensive information. The calculation algorithm was worked out by specialists with knowledge of norms and rules, as well as calculation methods. Trust their experience, in just 5 seconds you will have a lot of reliable information.

Step by step construction of a bath

erecting the foundation of a bath from a bar

reinforcement and waterproofing

Recall that the function of the foundation of the bath from the bar is the placement and retention of the frame of the log, roof and heating furnace. The average weight of structures can reach 2-3 tons. Therefore, for the foundation, it is expedient to use a strip foundation with the laying of reinforced concrete slabs in the steam room and shower room.

To create a foundation for digging a trench along the perimeter of the future structure, the width exceeding the width of the lower rim (it is necessary to count). Align and clean the trench walls, and then place the rubble and sand in a 50/50 ratio on the bottom. The layer is tampered with a manual rammer. To strengthen the corners of the foundation we use reinforcement A-I and A-II, from which we form the interstorey ladder.

The docking of the structure is made using vertical reinforcing bars placed along the height of the foundation. For elevation and lifting above the zero mark, we construct a formwork from the boards of multi-ply or edging boards. In the formwork, it is necessary to provide for the location of the outlet of the drain and the supply of water. Formwork rigidly fixed with the formation of the box. Pour the concrete into the formwork box.

Waterproofing is made on top of the finished foundation: the first layer of bituminous mastic, the second layer - the roll waterproofing material.

At the end of the reinforcement, pouring concrete and waterproofing the foundation, the installation of the lintel bar is made, on which the walls of the frame are formed.

erection of the walls of the bath

The construction of the walls of the log house of the bath is carried out along the following chain:

"Sorting of wood" - "waterproofing the foundation" - "preparation of joints of the timber".

first crown

To create the first log frame on the surface of the waterproof foundation, lay the wooden slats, which are a kind of barrier for germs and mold.

The first beam is laid on the slats and verifies the horizontal. The first (oprichnoy) crown is fastened with steel staples on the outside.

On a folding crown we place a heater. In the corners of the beams we join the butt-joint in such a way that each previous seam is blocked by the next one. For this, the end joint is cut at an angle of 90 degrees.

subsequent crowns

The subsequent wreaths of the log are installed in a similar way, fixing their position with a nail or a pin into the unloading holes. It is necessary to strictly observe the compliance of the diameters of the unloading holes and the diameters of the nails.

A slight deviation from compliance is acceptable. The last upper crown of the log is left loose and go to the device of the ceiling beams and the roof of the bath.

floor the floor with our own hands

A practical option is the rough flowing floor on the log joists, when the logs rest on a folding crown. The internal floor of the structure from the board is laid with allowance for the gap. The logs are placed on brick support chairs, under which monolithic platforms are laid. For the construction of chairs, dig a pit of 40 cm, corresponding to the width of the supporting chair.

At the bottom lay a layer of crushed stone and rammed. All supporting chairs are located in a single level, so their verticality is strictly controlled. Then concrete is poured into the formwork. The final stage of preparation for the chairs and lag is waterproofing.

Helpful Tips

For a non-leaking variant, it is recommended to create a slope of 10 ° with the use of cuts in the bar. For flooring, use sheet pile boards instead of trimming products. The technology of creating and warming the floor is as follows: "rough floor" - "claydite insulation" - "roll waterproofing".

All the useful tips for the construction of the bath from the bar, are presented in the video.